According to naval architects, ships must always be capable of dealing with a wide range of external and internal factors that may affect their seaworthiness and the safety of their crew or passengers.

For timber deck cargoes, the stowage and cargo securing arrangements should allow for a safe yet sensible securing of the cargo so that it is satisfactorily prevented from shifting.

The Intact Stability Criteria for Timber Deck Cargo ensures that timber deck cargoes are loaded, stowed, and secured in such a way as to avoid damage or danger to the ship and persons on board as much as possible throughout the voyage, as well as cargo loss overboard.

The International Maritime Organization developed the Code of Safe Practice for Ships Carrying Timber Deck Cargoes in 1972, which was later amended in 1978.

The code was revised and amended as needed to reflect the capability of today’s ships and the equipment available on board, as well as to account for expected future innovations.

The Code is intended to assist parties involved in timber carriage or manufacturing timber lashing equipment, as well as administrations involved in timber carriage legislation.

Ships carrying timber on their exposed decks are thus thought of as benefiting from additional buoyancy and therefore a higher level of protection from the sea. Ships arranged in this manner are given a smaller freeboard than would otherwise be assigned.

This write-up explains practices for the safe transportation of timber deck cargoes, methodologies for safe stowage and securing, and design principles for securing systems to be included in ships’ cargo securing manuals.

Why Is It Important To Have Intact Stability Criteria For Timber Deck Cargo?

Stability refers to the ability of a ship to remain upright and afloat in water. A ship must have enough stability to resist the forces that act on it, such as the wind, waves, and current. If a ship is not stable, it will eventually capsize or sink.

There are two types of stability: static and dynamic. Static stability is the ability of a ship to return to its upright position after being tilted. Dynamic stability is the ability of a ship to resist capsizing when it is moving through the water.

A ship’s stability is affected by several factors, such as its size, shape, and weight distribution. Properly managing these factors is essential to ensuring a ship’s safety. For timber deck cargo the Intact Stability Criteria ensures that timber cargoes carried on deck are loaded, stowed, and secured so as to avoid damage or hazard to the ship and persons on board as much as possible throughout the voyage, as well as cargo loss overboard.

It ensures the ship’s stability always stays positive and is usually computed by always taking into consideration the following factors:

The increased weight of the timber deck cargo as a result of the absorption of water and, if appropriate, the accumulation of ice, variations in consumables (such as the use of fuel from tanks low down in the ship); The weight of water that is trapped in broken gaps within the timber deck cargo, particularly logs, and the free surface effects of liquids that are stored in tanks are also taken into account.

In addition, because ships carrying timber deck cargoes should as much as possible operate with a margin of safety with respect to the metacentric height (GM), the intact stability criteria for Timber Deck Cargo recommends the metacentric height should preferably not exceed 3% of the breadth of the ship in order to prevent excessive accelerations in rolling that would cause large racking stresses and high stresses on cargo lashings, both of which could result in cargo loss or shift.

What Are the Intact Stability Criteria for Timber Deck Cargo?

As per Chapter 4 Regulation 4.1 of the Code on Intact Stability, the minimum intact stability requirements for cargo ships 24 meters in length and over-engaged in the carriage of timber deck cargoes that make use of their timber load line should also comply with the following requirements:

1. The area under the righting lever curve (GZ curve) should not be less than 0.08 meter-radians up to θ = 40° or the angle of flooding if this angle is less than 40°.

2. The maximum value of the righting lever (GZ) should be at least 0.25 m.

3. At all times during a voyage, the metacentric height GMo should not be less than 0.10 m after correction for the free surface effects of liquid in tanks and, where appropriate, the absorption of water by the deck cargo and/or ice accretion on the exposed surfaces. (Details regarding ice accretion are given in chapter 5).

4. When determining the ability of the ship to withstand the combined effects of beam wind and rolling according to 3.2, the 16° limiting angle of the heel under the action of steady wind should be complied with, but the additional criterion of 80% of the angle of deck edge immersion may be ignored.

How Can You Ensure That Your Timber Deck Cargo Is Securely Lashed?

To achieve a secure stowage for timber deck cargo, I would ensure that uprights designed in accordance with the relevant flag state rules are used when required by the nature, height, or character of the timber deck cargo.

Where timber uprights are used, it is the responsibility of the Master to use timber of a type and grade proven satisfactory for the purpose. Uprights would be used for all timber deck cargoes with the exception that, where only packaged timber is to be carried, uprights may be omitted.

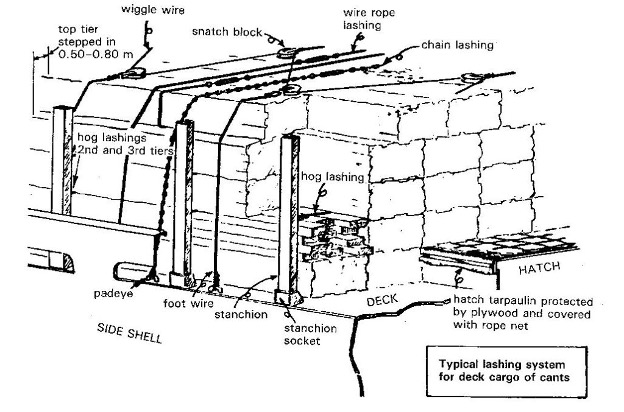

To ensure support for the uprights, deck sockets would be used to provide strong “footholds”, along with a locking pin, of adequate strength to hold the uprights in place. Strong permanent bulwarks, or efficient rails of especially strong construction, would be fitted. They are acceptable as supports for uprights, provided they have adequate strength, and substantial sockets are built for each upright.

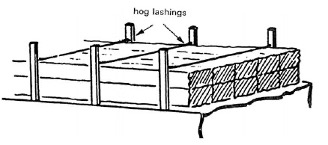

The spacing of the uprights is to be suitable for the length and character of the timber to be carried but is not to exceed 3 meters, with each upright extending above the top of the cargo and fitted with a strap or bracket support at the top of the bulwark to hold it upright whilst loading. Hog wires that run transversely are used at approximately three-quarters of the height of the stow to connect the respective port and starboard uprights. They are connected by pad eyes attached to the uprights at this level.

The timber deck cargo is to be secured along its length by appropriate top-over lashings with the spacing of lashings being such that lashings are positioned as close as practicable to the ends of each continuous timber deck stow. Lashings and fittings must have adequate strength for the proposed timber loading and must not show any permanent deformation.

Every lashing is to be provided with a tightening device or system, situated so that it can be safely and efficiently operated when required.

Slip hooks or other appropriate methods may be used for quick and safe adjustment of lashings.

Once the lashings are secured, the tightening device is to have not less than half the tightening capacity available for further use. Pelican hooks, when used, are to be moused.

There must be arrangements made for the safe emergency jettisoning of cargo.

What Else Should You Consider Carrying Timber Deck Cargo?

The timber deck cargoes will be stowed and lashed in accordance with the vessel’s cargo securing manual The stow will extend for at least the entire available length, that is the total length of the well or wells between superstructures. If there is no limiting superstructure at the back end, the timber will extend at least to the back end of the last hatchway. In Athwartships the timber deck cargo is to extend as close as possible to the ship’s side, with due allowance being made for obstructions..

The timber would be stowed as solidly as possible to at least the standard height of the superstructure other than a raised quarter-deck. It is not to interfere in any way with the safe navigation and necessary work of the ship. On a ship within a seasonal winter zone in winter, the height of the deck cargo above the deck exposed to weather must not exceed one-third of the extreme breadth of the ship.

A walkway will be provided over the timber deck cargo if there is no convenient passage on or below the ship’s deck. This walkway will be located at or near the ship’s centerline and will be made up of two sets of guard wires separated by about a meter, with each side made up of three wires separated by more than three courses of wire. The guard wires must be attached to stanchions. The stanchions must be no more than 3 m apart and secured to the timber cargo with spikes or other equivalent means.

A safe walking surface of at least 0.5-meter width will be installed over the cargo and securely fastened to the top of it in line with the walkway or adjacent to the lifeline. All lines must be tautened with tightening devices. Access to the top of the timber deck cargo must be made safe using properly constructed ladders, steps, or ramps equipped with guard lines or handrails. A wire lifeline will be installed along the ship’s centerline, adequately supported by stanchions spaced no more than 10 m apart.

Openings in the weather deck must be able to be properly closed and secured tight, and ventilators, air pipes, and other fittings enclosing openings must be adequately protected against damage. Access hatches, vents, air pipes, fire hydrants, hoses, valve operating positions, sounding pipes, and other critical equipment will be clearly labeled and accessible.

Conclusion.

The Code has been created to ensure that stowage and cargo securing arrangements for timber deck cargoes allow for a safe yet rational securing of the cargo, and also satisfactorily prevents it from shifting. It considers the acceleration forces that the cargo may experience during the voyage.

It specifically addresses safe transportation practices, methodologies for safe stowage and securing, design principles for securing systems, and guidance for developing procedures for inclusion in ship cargo securing manuals.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply