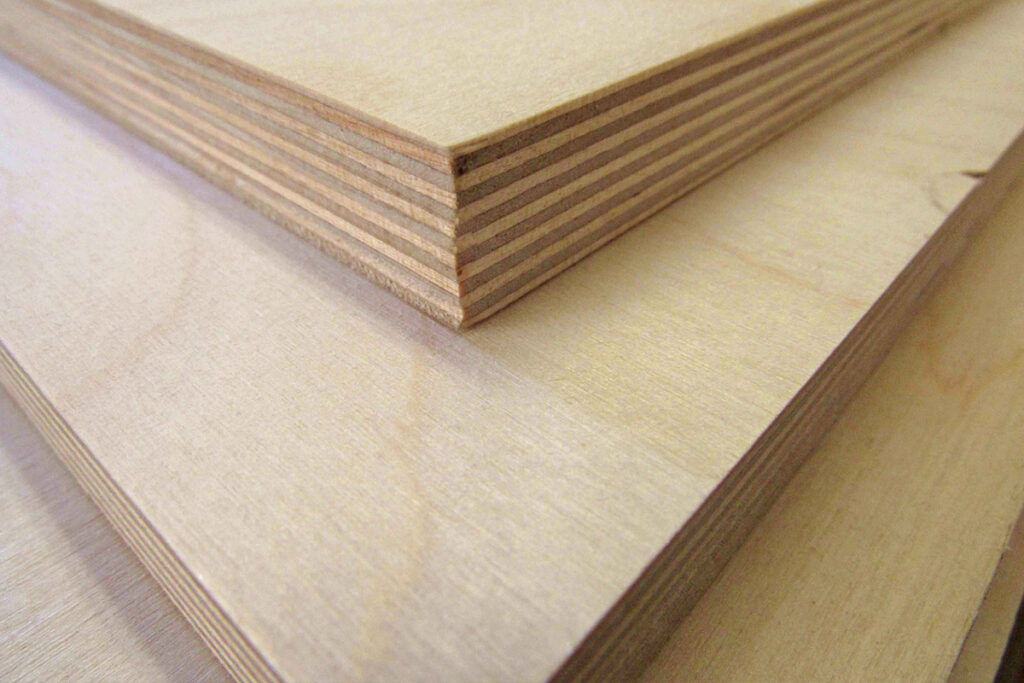

Marine plywood is a specialized type of plywood that is designed to withstand exposure to water and moisture. It is often used in boat building, docks, and other outdoor applications where water resistance is critical.

Marine plywood comes in different grades, each with unique properties and characteristics that make it suitable for specific applications. In this article, we will explore the different grades of marine plywood, their features, and how to choose the right grade for your project.

What are the Grades of Marine Plywood?

Marine plywood is made from hardwood veneers bonded together with waterproof adhesive. It is designed to be highly resistant to moisture, rot, and warping, making it ideal for use in marine applications. Marine plywood is available in different grades, each with unique features and qualities that make it suitable for specific applications.

Here is a comprehensive comparison table for all types of grade marine plywood, including MDO and HDO:

| Grade | Description | Strengths | Weaknesses | Recommended Use |

|---|---|---|---|---|

| A-A | High-grade marine plywood with no visible defects, knots or voids | Excellent water resistance and durability, high stability and excellent appearance | Most expensive grade of marine plywood | Below the waterline applications, yachts, boats, docks, piers, decks and other marine applications. |

| A-B | High-grade marine plywood with some visible defects, knots or patches | Good water resistance and durability, high stability and good appearance | Not as expensive as A-A grade but still relatively expensive | Above-the-waterline applications, yachts, boats, docks, piers, decks and other marine applications |

| B-B | Lower-grade marine plywood with visible defects such as knots or voids, but still some quality | Moderate water resistance and stability, affordable price uniform surface finish | More noticeable defects, less stable and prone to warping, swelling, etc. | Outdoor applications such as subfloors, roofing, sheathing and some marine applications such as decking |

| MDO | Marine plywood with a layer of MDO or HDO on one or both faces improving water resistance | Good water resistance and durability, high stability and smooth, uniform surface finish | More expensive than B-B grade, but still affordable compared to A-A and A-B grades | Signage, concrete forms, and some marine applications such as docks, and piers |

| HDO | Marine plywood with a layer of HDO on one or both faces improving water resistance and | Excellent water resistance and durability, high stability and smooth, uniform surface finish | More expensive than MDO and B-B grades, but still affordable compared to A-A and A-B grades | Marine applications such as docks, piers, and boats |

It is important to choose the appropriate grade of marine plywood based on the specific application and project requirements. The higher the grade of marine plywood, the better its water resistance, durability, stability, and appearance, but also more expensive. MDO and HDO grades offer improved water resistance and a uniform surface finish, making them suitable for certain marine and outdoor applications.

Grades of Marine Plywood

A-A Grade Marine Plywood

A-A grade marine plywood is the highest quality marine plywood available in the market. It is made from top-quality hardwood veneers that are carefully selected for their uniform color and grain pattern, with no defects, knots, or voids. The veneers are bonded together with waterproof adhesive using a process called cross-banding, where each layer is oriented perpendicular to the previous layer.

The cross-banding process gives A-A grade marine plywood superior strength, stability, and resistance to warping and twisting. The plywood is also sanded smooth to provide a uniform surface finish that is free of bumps, rough spots, and patches.

A-A grade marine plywood is highly resistant to water, moisture, and rot, making it ideal for boat building, docks, and other outdoor applications where water resistance is critical. It is also suitable for applications where appearance is important, such as cabinetry, furniture, and decorative panels.

When using A-A grade marine plywood, it is important to follow proper installation techniques and use the appropriate fasteners and sealants to ensure maximum performance and longevity. A-A grade marine plywood can be more expensive than other grades, but its high quality and superior performance make it a worthwhile investment for many marine applications.

A-B Grade Marine Plywood

A-B grade marine plywood is a high-quality plywood that is commonly used for marine applications. It is made from hardwood veneers that are carefully selected for their uniform color and grain pattern, with no defects, knots, or voids. The veneers are bonded together with waterproof adhesive using a process called cross-banding, where each layer is oriented perpendicular to the previous layer.

The cross-banding process gives A-B grade marine plywood good strength and stability, although not as much as A-A grade marine plywood. It is also sanded smooth to provide a uniform surface finish that is free of bumps, rough spots, and patches.

A-B grade marine plywood is highly resistant to water, moisture, and rot, making it suitable for boat building, docks, and other outdoor applications where water resistance is important. It is also suitable for applications where appearance is not as critical, such as subfloors, roofing, and sheathing.

Compared to A-A grade marine plywood, A-B grade marine plywood may have slight color variations and some minor defects, such as knots or voids, that do not affect its performance or durability. However, it is still a high-quality plywood that is suitable for many marine and outdoor applications.

When using A-B grade marine plywood, it is important to follow proper installation techniques and use the appropriate fasteners and sealants to ensure maximum performance and longevity. A-B grade marine plywood is often more affordable than A-A grade marine plywood, making it a good choice for those on a budget who still require high-quality plywood for their marine or outdoor projects.

B-B Grade Marine Plywood

B-B grade marine plywood is a lower-grade marine plywood that is still suitable for some marine and outdoor applications. It is made from hardwood veneers that may have some defects, such as knots, voids, or patches but are still selected for their uniform color and grain pattern. The veneers are bonded together with waterproof adhesive using a process called cross-banding, where each layer is oriented perpendicular to the previous layer.

The cross-banding process gives B-B grade marine plywood some strength and stability, although not as much as A-A or A-B grade marine plywood. It is also sanded smooth to provide a uniform surface finish that is free of bumps, rough spots, and patches.

B-B grade marine plywood is resistant to water, moisture, and rot, but not as much as A-A or A-B grade marine plywood. It is suitable for some marine applications, such as decking, but not recommended for below the waterline applications. It is also suitable for outdoor applications where appearance is not as critical, such as subfloors, roofing, and sheathing.

Compared to A-A and A-B grade marine plywood, B-B grade marine plywood may have more noticeable defects, such as knots or voids, that may affect its appearance and durability. However, it is still a decent-quality plywood that is suitable for some marine and outdoor applications.

When using B-B grade marine plywood, it is important to follow proper installation techniques and use the appropriate fasteners and sealants to ensure maximum performance and longevity. B-B grade marine plywood is often the most affordable option for marine and outdoor projects, making it a good choice for those on a tight budget who still require decent-quality plywood for their projects.

Medium-density overlay (MDO) grade marine plywood

Medium-density overlay (MDO) grade marine plywood is a specialized type of plywood that is made by overlaying a resin-impregnated fiber on top of a traditional plywood panel. This overlay is typically made of paper, but it can also be made of fiberglass or other synthetic materials. The overlay is then bonded to the plywood core under high heat and pressure, resulting in a strong and durable panel that is resistant to water, weather, and other environmental conditions.

MDO grade marine plywood is commonly used for outdoor and marine applications, such as signs, billboards, exterior doors, boat building, and concrete formwork. The overlay provides a smooth and even surface that is ideal for painting, while the underlying plywood core provides strength and stability.

MDO grade marine plywood is available in a range of thicknesses, from 1/4 inch to 1 inch or more. It is typically sold in sheets that are 4 feet by 8 feet, although other sizes may also be available. The grade is categorized based on the quality of the overlay surface and the core veneers, with A and B grades being the most common.

One of the main advantages of MDO-grade marine plywood is its durability and resistance to moisture and weathering. It is also relatively easy to work with, as it can be cut, drilled, and shaped using standard woodworking tools. Additionally, MDO grade marine plywood is less expensive than other marine-grade plywood options, making it a popular choice for budget-conscious projects.

However, MDO-grade marine plywood also has some disadvantages. The overlay surface can be prone to cracking or peeling if not properly maintained, and the plywood core may not be as strong as other marine-grade plywood options. Additionally, MDO-grade marine plywood is not recommended for applications that require high levels of impact resistance or structural support.

Overall, MDO-grade marine plywood is a versatile and cost-effective option for outdoor and marine applications. It provides a strong and durable surface that is resistant to moisture and weathering, making it a popular choice for a wide range of projects.

High-density overlay (HDO) grade marine plywood

High-density overlay (HDO) grade marine plywood is a specialized type of plywood that is similar to MDO grade marine plywood but with a higher density overlay. The overlay is typically made of resin-impregnated paper, and it is bonded to the plywood core under high heat and pressure to create a strong and durable panel that is resistant to water, weather, and other environmental conditions.

HDO-grade marine plywood is commonly used for applications that require high levels of strength and durability, such as concrete formwork, industrial flooring, and exterior structures like bridges and buildings. The high-density overlay provides a smooth and even surface that is ideal for painting or other finishes, while the underlying plywood core provides strength and stability.

HDO grade marine plywood is available in a range of thicknesses, from 1/4 inch to 1 inch or more, and it is typically sold in sheets that are 4 feet by 8 feet. The grade is categorized based on the quality of the overlay surface and the core veneers, with A and B grades being the most common.

One of the main advantages of HDO-grade marine plywood is its exceptional durability and resistance to moisture, weathering, and abrasion. The high-density overlay provides a hard and smooth surface that is resistant to wear and tear, making it an ideal choice for applications that require high levels of strength and durability.

However, HDO-grade marine plywood also has some disadvantages. It is typically more expensive than other marine-grade plywood options, and it can be difficult to work with due to its high density and hardness. Additionally, HDO-grade marine plywood may not be suitable for applications that require high levels of impact resistance or flexibility.

Overall, HDO-grade marine plywood is a strong and durable option for applications that require exceptional strength and resistance to moisture and weathering. It provides a hard and smooth surface that is ideal for painting or other finishes, making it a popular choice for industrial and commercial projects.

How to Choose the Right Grade of Marine Plywood

Choosing the right grade of marine plywood is essential for ensuring that your project has the necessary strength, durability, and moisture resistance to perform well in marine or outdoor environments. Here are some quick tips for selecting the right grade of marine plywood for your project:

- Consider the application: The grade of marine plywood you choose will depend on the specific application. If appearance is important, such as for a high-end yacht or boat, A-A grade marine plywood may be the best option. For applications that prioritize strength and durability, A-B or B-B grade marine plywood may be suitable. MDO and HDO grades are ideal for applications that require exceptional strength and a smooth, even surface.

- Evaluate the veneers: Look closely at the face and back veneers of the marine plywood. A-A grade will have a high-quality veneer on both sides, while A-B grade will have a high-quality veneer on one side and a lower-quality veneer on the other. B-B grade will have lower quality veneers on both sides.

- Check for voids: Check the core of the marine plywood for any voids or gaps. The presence of voids can weaken the strength and durability of the plywood.

- Consider the cost: Higher grades of marine plywood typically come at a higher cost. Consider your budget and the specific requirements of your project when selecting a grade of marine plywood.

By considering the application, veneers, voids, and cost, you can choose the right grade of marine plywood to ensure the success of your project.

Conclusion

Marine plywood is an essential material in boat building, docks, and other outdoor applications where water resistance is critical. Understanding the different grades of marine plywood can help you choose the right grade for your project. Whether you need a high-quality plywood with a smooth surface finish or rough plywood suitable for subflooring, there is a grade of marine plywood that is suitable for your needs.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025