Have you ever wondered what the interior of a commercial ship hull looks like? What might be the different subdivisions, tanks, and so on?

The aft peak tank is the last tank which acts as the primary structural support towards the aft of the vessel. It lies towards the aft of the aft peak bulkhead.

This compartment spans from the after-peak bulkhead to the stern frame and aft end of the ship. Let us get into more details to learn about the aft peak tanks’ uses, composition, and so on.

How Are The Aft Peak Tanks Designed?

Ships have had severe load issues in the fore and aft sectors over time, which has resulted in damage.

When compared to the fore half, the aft end is less affected by local loads. Fortunately, contemporary load prediction methods and FEM tools have created several opportunities for creative, reliable, and secure designs.

It is often used to store fresh water or ballast, and it protects all compartments ahead of the aft peak bulkhead. They are typically employed as ballast to ‘trim’ the ship, to maintain its level.

The majority of ships with current designs are highly resilient to aberrant local loads even in extremely choppy sea conditions. Ships are now safer thanks to more sophisticated strengthening techniques that are cost-effective.

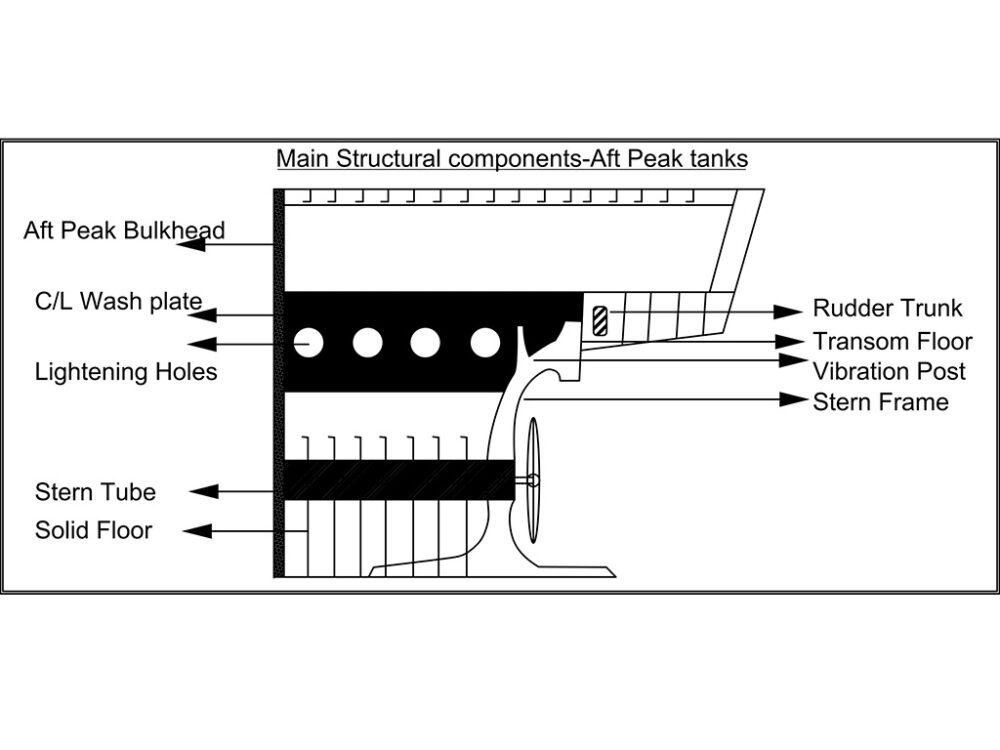

What Are The Main Structural Components In Aft Peak Tanks?

We restrict our discussion to the strengthening provisions made to the stern frame in response to resisting limited forces created in the rearward region, such as propeller-induced vibrations, sternward wave disturbances, and, to a lesser amount, panting and hammering.

Since the aft of the vessel is the part that houses the propeller and generates forces to drive the vessel forward, the aft peak comprises a majority of structural members and components such as,

- Stern frame

- Stern Tube

- Wash Bulkheads

- Cant Beams

- Rudder Trunk

- Transom Floor

Let us go more into the details of these components.

Stern Frame

The stern frame is used to house and support propulsion machinery such as the shaft, propeller, and rudder. The stern frame connects the shell plating at the aft end. The stern frame’s form is determined by the design of the stern, propeller, and rudder arrangement. Castings are most commonly utilized; however, fabrications and forgings are sometimes employed

The stern frame of single screw ships features a boss on the centerline for the tail shaft to pass through, as well as an appropriate aperture for the propeller to work in.

The rudder post may be supported by the lower half of the stern frame or gudgeons for the rudder pintles may be provided by an overhang section. Twin screw ships feature a stern structure that only supports the rudder pintles and is thus substantially less in size.

Various elements of the stern frame serve as connection points to the aft end construction’s various levels. Two distinct connections are the transom post and the vibration post. These connectors guarantee that propeller-induced vibrations are kept to a minimum.

The bossing configuration will alter for ships with more than one tail shaft. Excessive trim on the vessel should be avoided during drydock since it increases the risk of stern frame damage because the stern frame hits the block first.

Stern Tube

The aft peak tank also houses the stern tube through which the propeller shaft and bearings can be found. The propeller shaft within the stern tube might be oil or water lubricated.

The bearings are constructed of white metal, a tin alloy, for oil lubrication. Oil seals are necessary for the stern tube’s inboard and outboard ends. Oil seals have mostly replaced water-lubricated ones on modern ships due to increasing bearing loadings caused by slow-speed shafts and larger propellers.

Bearings for water-lubricated stern tubes are constructed of lignum vitae (a species of wood) or synthetic materials. The outboard end of the stern tube is not waterproof in this case to enable circulation of seawater within the stern tube, but the inboard end of the stern tube must be watertight to keep the engine room dry.

Wash Bulkheads

A centerline longitudinal wash bulkhead is typically installed to prevent free surface effects. Vertical stiffeners and girders are used to stiffen the centerline wash bulkhead as needed to withstand the forces from sloshing.

Cant Beams

Cant beams are an intriguing element of aft-end strengthening solutions. Cant beams help to provide longitudinal and transverse strength to the stern arrangement. They are radial in nature and are directly welded to the shell plate, resulting in a web frame structure. Cant beams are frequently paired with cant frames to provide additional strength.

Rudder Trunk

The rudder trunk is a portion at the stern that allows the rudder stock to enter the steering gear area. The trunk above this is then built to be waterproof, with just the rudder stock penetrating it. The bottom section of the rudder trunk is exposed to the water but normally has an inspection hatch for accessibility and maintenance.

Transom Floor

A large centerline girder and side girders are installed. Every frame, from the aft peak bulkhead to the aft end of the vessel, has transverse solid plate flooring. Aft peak also has a similar system of stringers with 2.5m of spacing.

The graphical representation can be found on this diagram of the aft peak tank.

The Aft Peak Tanks Differences On Bulk Carriers And Tankers

In Bulk Carrier and Container vessels, the engine room is often where the Ballast Water Treatment System (BWTS) is located. The main ballast or a separate fire pump, Bilge and Ballast Pumps may be linked to the aft-peak tank. The BWTS may be attached to the aft peak tank in either situation.

On Tankers, the gas safe zone is where the aft peak tank is located at. The main ballast tanks’ ballast is regarded as “hazardous.” Even though the Filter and other components of certain Slip-Stream BWTS may be situated inside the engine room, they are in a dangerous area. Consequently, the Aft Peak tank and the main ballast system’s water should not be mixed. Installing a separate Ballast Treatment System for the Aft Peak is a quick but pricey solution.

Summary

The aft peak tank is one of the most important sections of a hull as it not plays a huge role in the safety of a vessel but also helps with controlling trim, and housing important machinery and structural members in a vessel.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply