A steering gear system is a group of equipment working together for the sole purpose of providing direction for the ship while it is moving at the sea. The steering gear system allows the ship to turn from port (left) to starboard (right), starboard (right) to port (left), or to hold a certain heading to the boat as directed.

In modern days, vessels are equipped with either a hydraulic system or a combination of electric and hydraulic systems (electro-hydraulic).

Ship Steering Gear Working Principle

Usually, the steering gear system of a vessel is operated at the wheelhouse or bridge control or in some small crafts also in the flybridge.

In emergency cases, the steering gear is also operated locally – the steering gear room is a boat space where the steering gear power unit, telemotor cylinders, rudder stem, etc. is found. The steering gear room is located normally on the first bulkhead right above the rudder blade/s.

In a typical ship operation the captain or pilot issues the heading the ship must go on a course, the helmsman then turns/set the rudder blade angle thru the steering controller that order and keep it steady until the next order is given. The rudder angle is confirmed by the rudder angle repeater also located at the wheelhouse.

In an emergency operation, the helmsman is operating the steering system locally thru a manual operating wheel or a solenoid valve that is pressed in either direction as so to move the rudder port or starboard. The captain’s order is given thru a telephone accessible at the local operating station.

Like other crafts, planes, and even some cars, the vessel is equipped with autopilots. These autopilots take over the steering control once activated whenever the vessel sailing in the open sea. The autopilot is electronic equipment that controls the movement of the rudder to follow the waypoints plotted to complete a voyage.

Ship Steering Gear SOLAS Requirement

The steering gear system is a critical system aboard as explained above steering system is vital for maneuvering the vessel. The international convention for the Safety of Life at Sea (SOLAS) has issued requirements and regulations to be kept by every ship to be considered seaworthy. On a technical note, a few points relating to the ship’s steering gear system are as follows;

- The steering gear room must be an isolated section from vessel machinery and is always/ readily accessible.

- The vessel must be equipped with a main and auxiliary steering gear arrangement

- The main and auxiliary steering gear system must be able to work independently in any case of system failure one system the ship still has the means to maneuver at sea

- The main steering gear system must be able to move the rudder from 35 degrees to 30 degrees either port to starboard or starboard to port within 28 seconds while at full speed and full load condition. The same criteria apply for full astern propulsion

- The auxiliary steering gear system must be able to move the rudder from 15 degrees to left 15 degrees or vice versa within 60 seconds on a speed not less than 7 knots at full loaded conditions.

How Does A Ship Steering System Work?

Generally, the steering gear works through the linkage between its three main parts – a telemotor, a control unit, and a power unit. The order to change the rudder angle by means of a telemotor which has a transmitter and receiver end.

The transmitter end is like the order input where the wished rudder angle is given. The telemotor then transports this order to its receiver end which is connected to a control unit. The control unit, as the name suggests, controls the power unit which moves the rudder from one position to another and the order the control unit receives until the next one. This power unit produces force to displace the rudder/s at which the control unit is ordered to.

The power unit is linked to rudder stem/s which synchronizes the motion of the rudder blade and the power unit. The rudder is also linked with a rudder angle transmitter which fed information to the rudder angle repeater on each steering gear control station (steering gear room, wheelhouse, and flybridge) or in some designs even on the captain’s office/cabin.

In clarification, the working principle of the steering gear tackled until this point is the follow-up (FU) mode of steering gear used in the ship. To emphasize, the FU steering gear mode turns the rudder on an angle it is ordered to and remains in position while the other mode is called non follow up (NFU) mode.

The NFU mode moves the rudder to the angle it is directed to but upon reaching the ordered position the rudder angle goes to an off position or amidship position.

Types Of Steering Gear In The Ship

There are two types of steering gear in ships. The types are classified based on the power unit or the driving force it uses. They can be either fully hydraulic or electro-hydraulic.

Fully Hydraulic Steering Gear

Fully hydraulic type, the manual hydraulic pump is moved clockwise or counterclockwise. This movement pumps the oil to a solenoid directional valve which moves the ram that is attached to the steering control.

The ram movement that is parallel to the rudder, left or right turns the rudder blade on a certain angle port and starboard. This type of hydraulic linkage is purely mechanical in nature and does not require electricity to be operated.

They are widely used during earlier times but are still fitted in present times as auxiliary steering gear arrangements on small boats.

Electro-hydraulic Steering Gear

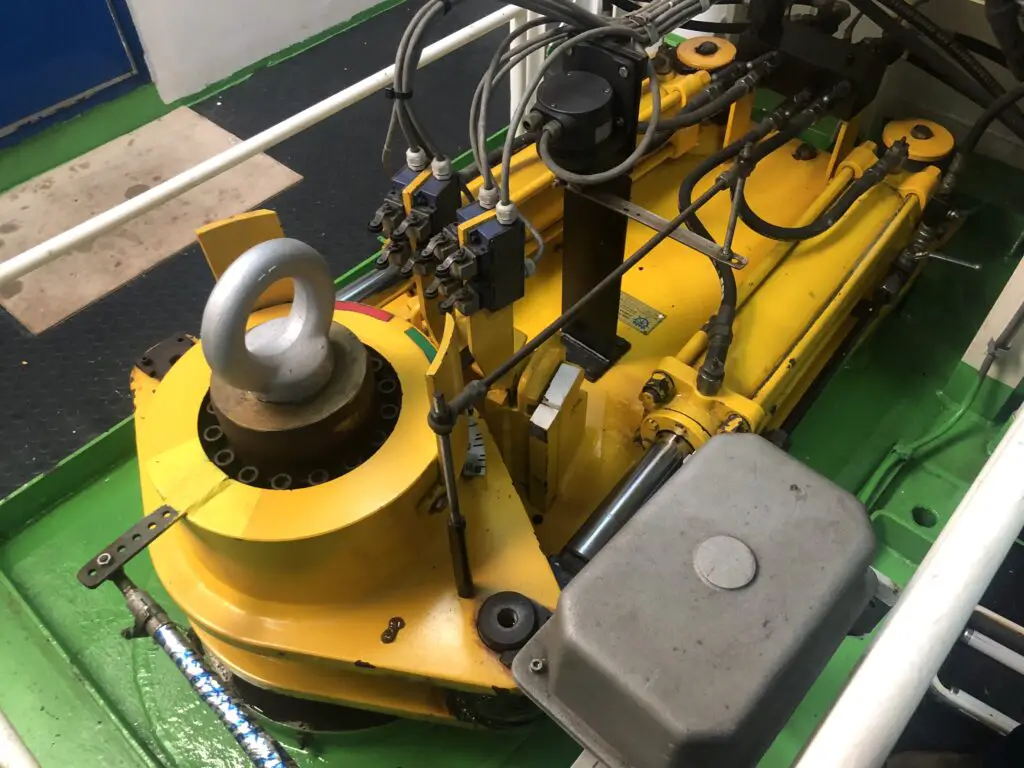

Electro-hydraulic type is the type of steering gear arrangement that is vastly used by merchant marine ships nowadays. The same principle applies only to this arrangement uses electric motors to drive the hydraulic fluid to the cylinder and allow movement of the rudder blades.

They are commonly operated by a tiller joystick that is fitted on the wheelhouse. The joystick gives an electrical signal to the control unit to open and close hydraulic valves to move the rudder at the desired direction and angle.

The auxiliary arrangement of such types is connected to an emergency power source usually emergency alternators to power up the system and provide ship steering means even at times of power failure.

The Main Parts Of The Marine Steering Gear System

Three main parts of the marine steering gear system were briefly discussed earlier. The main parts of the marine steering gear system are the telemotor, the control unit, and the power unit. These parts shall be discussed deeply in the following section of this article.

Steering Gear Telemotor

Telemotor is the unit where the desired angle is ordered to. The telemotor carries the information/order from the wheelhouse or steering control station to the steering gear room by mechanical or electrical means.

A transmitter is placed on the wheelhouse which forwards the order to a receiver located in the steering gear room that is directly connected to a control unit.

Telemotor in a broad sense is the assembly consisting of the steering wheel or tiller joystick and pipes and electrical cables or mechanical linkage going to the steering gear room. For more details about telemotor functions read this article.

Steering Gear Control Unit

The Control Unit is the part where it receives and processes the information given by the telemotor. This unit consists of a motor pump that controls a small hydraulic power unit which consists of a tank solenoid valve and ram. The control unit upon receiving the order from the telemotor pumps the oil in a certain direction to allow movement of a cylindrical ram. This cylindrical ram moves lateral and is connected to a floating or hunting lever attached to the power unit’s main pump.

Steering Gear Power unit

The power unit is the last phase of the steering gear system where the order is delivered. The power unit provides the power and torque needed to move the rudder blades to the angle it is desired to. And as mentioned as well in some arrangements it generates the force required to hold the rudder on its position/angle.

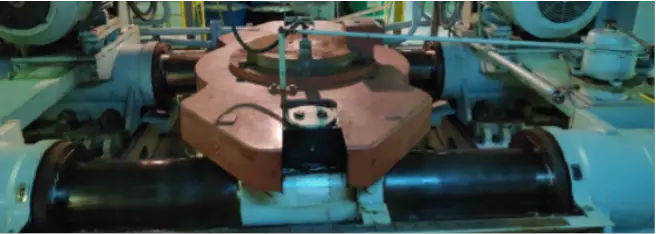

The power unit is a hydraulic pump (radial piston type or axial piston type) driven by a big electrical motor which like in the control unit pumps the oil to a cylindrical block that moves parallel to the rudder. With the help of mechanical linkage, cylinder movement is translated to rudder movement.

Ship Steering Gear Preparation and Onboard Drills

Quarterly, the ship’s crew is trained through ships safety drills in operating the ship’s emergency steering gear control. On how it is operated and the scenario role-playing in the emergency situation. This drill is also a regular means of checking the communication equipment between the steering gear room and the wheelhouse. As well as, ensuring that the emergency steering gear is in good working condition.

Twelve (12) hours before vessel departure, main and auxiliary steering gear operation, control, and power supply are tested and ensured for good operating condition. Correctness/calibration of the rudder angle in the local operating station is checked to be in parallel with the wheelhouse rudder angle feedback.

Lastly, it is also ensured that the communication system between the steering gear room and bridge is established and is in ready for operation

One hour before the vessel’s departure, a control test or functionality test is also made. This test is executed by powering up the steering control and turning the rudder at different angles.

Final words

The described system is commonly called ram type steering gear system. As the technology keeps rapidly evolving many designs of the steering gear are created although its core principle still remains intact on each system. One also known steering system design is the rotary vane steering gear system, the difference it has from the one greatly discussed is that instead of a ram it uses vanes that rotates in a fixed housing.

In addition, in this steering gear discussion as vital, it is being redundantly reiterated it is maintained often and regularly aboard.

FAQs About Steering Gear in Ships

What is the purpose of a steering gear system on a ship?

The purpose of a steering gear system on a ship is to provide direction and control the movement of the vessel while it is at sea, allowing it to turn from port (left) to starboard (right), starboard to port, or maintain a specific heading as directed.

How does a ship’s steering system work?

A ship’s steering system works through the linkage between its three main parts: the telemotor, control unit, and power unit. The telemotor receives the desired angle order from the wheelhouse and transmits it to the control unit, which in turn controls the power unit. The power unit generates the force necessary to move the rudder blades to the desired position, synchronizing their motion with the control unit’s orders.

What are the types of steering gear systems used on ships?

There are two types of steering gear systems used on ships: fully hydraulic and electro-hydraulic. Fully hydraulic systems use a manual hydraulic pump to control the movement of the rudder blade, while electro-hydraulic systems utilize electric motors to drive the hydraulic fluid and control the rudder’s direction and angle.

What are the main components of a marine steering gear system?

The main components of a marine steering gear system are the telemotor, control unit, and power unit. The telemotor receives the desired angle order, the control unit processes the information and controls the power unit, and the power unit delivers the power and torque needed to move the rudder blades to the desired position.

What are the SOLAS requirements for a ship’s steering gear system?

The Safety of Life at Sea (SOLAS) requirements for a ship’s steering gear system include the following:

The steering gear room must be an isolated section, readily accessible, and separate from other vessel machinery.

The vessel must be equipped with both a main and auxiliary steering gear arrangement.

The main and auxiliary steering gear systems must be capable of working independently, ensuring maneuverability in the event of a system failure.

The main steering gear system must be able to move the rudder from 35 degrees to 30 degrees port or starboard within 28 seconds while at full speed and full load condition. The same criteria apply for full astern propulsion.

The auxiliary steering gear system must be able to move the rudder from 15 degrees to left 15 degrees or vice versa within 60 seconds, at a speed not less than 7 knots under full loaded conditions.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply