Can you identify the difference between and compare carbon fiber vs fiberglass? Contrary to what many people think, they are not the same thing.

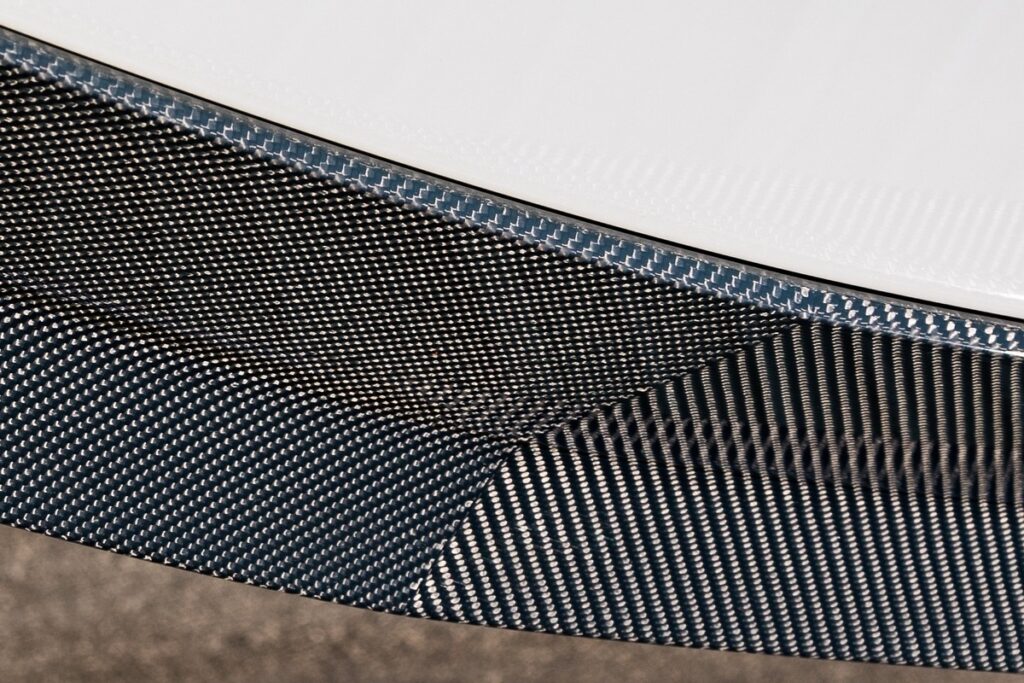

Both carbon fiber and fiberglass are composite reinforcing materials. Although both carbon fiber and fiberglass are composite materials, the fundamental distinction between the two is that while carbon fiber is created from strands of carbon atoms, fiberglass is made from melted glass strands.

But you’ll need to be aware of the distinctions between them to determine which is best for you in terms of both physical and mechanical properties. You’ll discover that each carbon fiber and fiberglass material have distinct qualities and offer unmatched performance in a variety of applications.

In this article, we will get into more detail to find out the main characteristics of both fibers, their significant differences, and so on.

Main Characteristics Of Fiberglass

Fiberglass is commonly used because it is considered to be a “cheap” and affordable material. If made properly, it delivers enough rigidity and strength. They are normally used as material to make boats, pools, and other structural elements.

The glass is made from specially chosen raw materials in a special oven that operates at a temperature of about 1.550 °C (E-glass). The white-hot mass is then taken out of the oven and forced into a platinum alloy bushing.

The “fibring technique,” which involves straightening the molten glass at high speed after it is withdrawn from the bushing’s perforations, creates a single glass thread. This technique generates threads that range in size from 50 to several thousand at once, characterized by their diameter (between 5 and 24 microns; 1 m = 1/1000 mm). To construct the strand, the threads are gathered together.

To create the roving, the strand (an assemblage of threads) is wound on reels, and to create yarn, the strand can also be twisted.

What Are The Different Classifications Of Fiberglass?

Fiberglass can be classified into the following.

- E-Glass: Cheapest, most common, and a good compromise is E-Glass.

- S Glass: + 25% tensile strength, regarded as a strategic material (military), and not commercially available

- 2 Glass: This type of fiberglass has the same composition as glass S, but is of inferior quality overall despite having longer fibers than glass S.

- R Glass: Made in France and comparable to S2

- C Glass: Excellent chemical resistance; utilized in chemical tanks

Main Characteristics Of Carbon Fiber

The polymer known as carbon fiber is also known as graphite fiber. Additionally noted for being strong and highly resilient. Crystalline carbon filaments reinforce the substance. Carbon fiber is exceedingly thin, so it only gains strength when it is weaved together. Additionally, it is lighter and more resistant to chemicals. It is frequently found in race cars, the aerospace industry, and other highly advanced products.

PAN, rayon, or pitch-based polymers are used to create the majority of carbon fiber. PAN makes up 90% of the carbon fiber produced, with the remaining 10% made of rayon or pitch-based polymer. Precursor polymers are used to create this fiber. These organic polymers are lengthy, carbon-atom-bound compounds. Precursor composition and the mechanical process used to spin the filament may differ for various manufacturers.

By 2031, the carbon fiber market is predicted to reach a value of over $8.9 billion, demonstrating how widely used and well-liked it is. On the other hand, carbon fiber has come to be associated with high performance and speed. Both carbon fiber and fiberglass are high-quality fibers that may reinforce engineering-grade products when used in 3D printing.

What Are The Different Classifications Of Fiberglass?

Based on the modulus, tensile strength (of the fiber components), and temperature of the final heat treatment, there are various varieties of carbon fiber. Temperature exposures during the carbonization process range from 1000°C to 2000°C, and each level of exposure gives fibers a unique feature.

The following are the main classifications,

- Various carbon fiber types based on modulus

- Ultra-High Modulus (Modulus > 500GPa)

- High modulus (Modulus 300-500GPa)

- Intermediate Modulus (Modulus 100-300GPa)

- Low modulus (Modulus 100GPa)

- Various Carbon Fiber Types Based on the type of Materials

- PAN (polyacrylonitrile)

- Based on mesophase pitch, carbon fiber

- Isotropic carbon fiber based on pitch

- Carbon fiber made with rayon

- Depending on the Final Heat Treatment Temperature, several types of carbon fiber

- Type I: The final heat treatment temperature for this carbon fiber is still above 2000°C. This kind of carbon fiber has a high modulus.

- Type II: This type’s final heat treatment temperature includes at least 1500°C, and this temperature produces high-strength type carbon fiber.

- Type III: This type’s final heat treatment temperature is approximately or below 1000°C, and at this temperature, low-strength carbon fiber is produced.

For instance, the high strength type is processed at 1500°C, the high modulus type at 2000°C, and the low modulus and low strength type at 1000°C.

The Significant Differences Between Carbon Fiber and Fiberglass

Although carbon fiber and fiberglass have similar qualities and are frequently used interchangeably in industrial and domestic applications, the following are the primary differences between the both

- Strength

Even though both materials are significantly more durable than steel, industrial carbon fiber is more than 20% more durable than the best fiberglass. Carbon fiber’s strength-to-weight ratio is almost twice that of fiberglass.

- Stiffness

Carbon fiber is the preferred material for applications where stiffness and rigidity are critical since it is substantially less flexible than fiberglass ex. mechanical components. The tensile modulus of carbon fiber is four times that of fiberglass.

- Weight

compared to fiberglass composites, carbon fiber typically weighs 15% less. Given their inherent strength, carbon fiber and fiberglass materials are incredibly lightweight in comparison to metals like steel and aluminum. Both materials are in great demand and utilized relatively regularly in contexts and applications where minimal weight is essential (aerospace or car racing, for example).

- Heat Expansion

In contrast to most substances, carbon fiber has a negative coefficient of thermal expansion, which causes it the substantially expand in colder temperatures. Although the carbon fiber itself has a negative coefficient of thermal expansion, the matrix does carry a positive coefficient, and the two usually cancel out to produce a coefficient of thermal expansion that is nearly neutral overall.

In technical terms, this means that carbon fiber materials do not contract in the cold, unlike fiberglass products. So, carbon fiber might be a better option if thermal expansion is a concern and extreme heat or cold is a factor.

- Corrosion Protection

You’ll be glad to know that either carbon fiber or fiberglass is quite resistant to corrosion or chemical abrasions, which is important if your application will be exposed to dangerous chemicals, acids, or abrasive environments.

- Cost

In general, fiberglass components are thought to be more affordable than their carbon fiber counterparts. This is large because fiberglass is used in a wider range of applications and has significantly lower manufacturing costs. There are fewer well-established manufacturers in the carbon fiber sector and the manufacturing process is much more complex.

Summary

Knowing the advantages and disadvantages of each material makes it simpler to choose between fiberglass and carbon fiber. You can use this information to determine which is best for your operations.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025