A free surface effect on a ship or road truck can have a significant impact on the stability of the maritime or road vessel. This can’t be ignored and requires a clear understanding!

The free surface of any confined space can be defined as the interface between two different states of matter and in our case on ships, it is the interface between liquid and air.

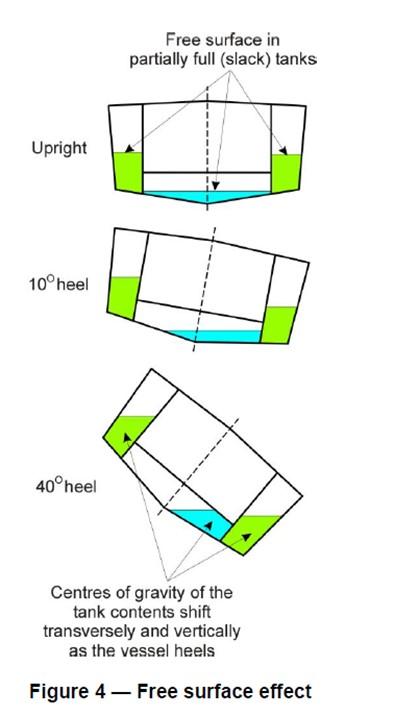

Let us take the example of an oil tanker, once the cargo is loaded into the tanks the fluids take up the shape of the tanks due to the effect of gravity, now if there are tanks that are partly filled, also called slack tanks, there is a free surface interface between the liquid cargo and air inside the tanks. The free surface effect can have an adverse effect on ships’ transverse stability.

Correlation Between Vessel Free Surface And Stability?

A vessel plying in the sea is subjected to external forces mostly from the waves which can affect her equilibrium and can give rise to motions in the six degrees of freedom mainly surge, sway, heave, roll, pitch, and yaw.

Let us consider a case where a vessel is subjected to roll motion, when the vessel rolls towards the port or starboard side correspondingly the liquid cargo inside the tanks tends to orient itself orthogonal to the force of gravity, or the liquid moves to the lower sides whereas if it was solid cargo, it would have maintained its position.

Due to the shift in the shape of the liquid cargo, weight also gets more concentrated to either side as per the phase of the roll motion which can bring a shift to the overall center of gravity along with a change in underwater volume.

Australian Maritime Safety Authority

Now this phenomenon is directly related to vessel stability as it decreases the values of initial metacentric height and the righting lever whereas it increases the values of the center of gravity.

Now as the vessel attains a new underwater volume, the center of buoyancy also changes and the downward force exerted by the center of gravity will be much more than the upward force from the center of buoyancy, which can cause the vessel to heel further and eventually capsize.

The effect of free surface also depends on the ratio of the density of the fluid within the tanks with respect to the density of the fluid in which the vessel stays afloat.

Which Type Of Vessel Has The Highest Free Surface Effect?

Generally, it can be observed that vessels that carry liquid cargo will have a higher free surface effect than those which carry bulk cargo or containers. Now further it can be noted that in the category of liquid tankers, oil tankers have the highest free surface effect as tanks are not fully filled taking into consideration that the oil inside the tanks needs to expand due to external temperature.

Analytical Tools For Computations

The flow inside any tank despite being either laminar or turbulent can be computed with the help of the Reynolds number. The analysis of the Reynolds number is done by studying the flow behavior with numerical computational software like CFD (Computational Fluid Dynamics).

There are further detailed studies done when the fluid inside tanks exerts a force on the vessel itself due to sloshing from external forces which can give rise to shallow water waves. All of these phenomena and their effects are studied with a specific set of numerical methods.

How To Reduce The Free Surface Effect On Vessels?

The generalized equation for the loss in stability due to free surface is provided below,

GM (Loss due to free surface) = Free surface moment X Specific gravity of liquid in a tank / Displacement of the vessel.

The following are the methods utilized to reduce the free surface effect on a vessel,

- Keeping slack tanks to a minimum.

By doing so we restrict the motion of the fluid which can further affect the stability of a vessel. During ballasting for different reasons, we should also consider either ballast a centerline ballast tank or transverse pair of ballast tanks to its maximum capacity.

- Tank subdivision

Tank subdivisions are done so as to reduce the effect of the free surface from effective damping by introducing transversal bulkheads within the tank which can reduce the moments within.

The bulkheads are also provided with an adequate number of openings so that there is no disruption of fluid flow without compromising on the effects which can arise due to free surface.

Regardless of the position of the tanks, the free surface effect can affect the vessel no matter if there is a tank on the uppermost or lowermost decks.

- Tank Geometry

The tank geometry also plays a crucial role in determining the vessel’s response to the free surface effect as the reduction of stability is directly linked to the area moment of the free surface alongside the tank’s midplane.

This implies that the lower the value of transversal area within a tank, the lower the moment of inertia associated along the tank’s midplane or centerline which corresponds to lower reductions in values of metacentric height and righting lever.

We should also be aware to reduce the effect of pocketing which is an effect caused when the liquid meets the top surface of the tank.

Conclusion

The free surface effect can play an adverse role in reducing the vessel’s intrinsic stability and can also decrease the comfort of passengers and crew onboard the vessel. The sloshing effect inside the tanks can also give rise to stresses acting on the tank walls, which may cause strain accumulations in the long run.

Proper measures should be considered to reduce the free surface effects before and during the voyage to ensure the safety of both the crew and the vessel.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025

Leave a Reply