When it comes to transporting goods, containers are a vital part of the process. But just how secure are they while in transit on ships at sea?

On the open sea, ships face harsh conditions and are subject to extreme forces. If containers are not secured properly, rough weather can quickly become a recipe for a disaster. So how are containers secured on ships for ocean voyages?

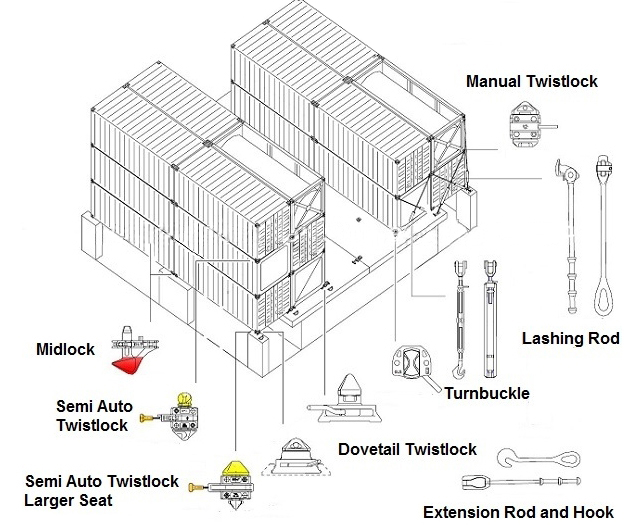

The containers are secured to each other in a stack and to the deck by twist locks or stacking cones, and each stack is secured additionally to the deck by lashing bars, which are anchored to the deck and container and tensioned by the use of turnbuckles.

Container Lashing is the process of securing the containers to minimize the possibility of them shifting while being transported on a ship. Lashing becomes extremely essential, especially when the containers are loaded on deck where the external forces are constantly encountered because of the motion of the ship in various directions.

Failing to secure containers correctly is one of the most common causes of container collapse. In this article, we shall look at the process of securing containers, which parties are involved, and the equipment used in securing containers.

How Are Containers Secured For Sea Transport?

The size of containerships has been increasing over the years, and this trend is expected to continue in the future. The largest containerships can carry up to 20,000 TEUs (Twenty-Foot Equivalent Units). However, large containerships are susceptible to strong rolling motion in heavy seas, which can place an excessive strain on the cargo securing systems.

This problem was highlighted in 2020 when heavy seas caused over 1800 containers on the MV ONE OPUS operated by Ocean Network Express to be lost or dislodged from its lashings. The incident was one of the increasing incidents that highlight the need for better cargo securing systems on large containerships.

In order to transport containers safely on the deck of a container vessel, they must be firmly attached to the ship. This is done by the use of twistlocks, which are inserted into slots in the container’s corner castings.

The twistlock’s revolving lug engages the slot holes in these corner castings and locks the containers together. In addition, lashing rods link the bottom two or three layers of the stacked containers to the deck of the ship.

Stowing stacks of containers on deck in such a way that the various stacks are connected to each other laterally, using specific stowage equipment such as bridge fitting was a typical practice at first. In contrast, today each stack stands alone, allowing it to be packed or unloaded without affecting adjacent stacks.

A ship transporting containers on deck thus transports a kind of “forest” of independent towers that sway back and forth in heavy seas because of the elasticity of the lashing material in much the same way that ears of corn in a field do.

Besides the twistlocks, lashing rods are positioned crosswise in front of and behind each container stack, to absorb lateral stack movements. Lashing bridges, as they are called running across the ship between the rows of containers, are provided to enable workers to stand on to lash higher-tier containers. This facilitates easier lashing of the 5th and higher tier containers, especially for bigger container ships.

Who Is Responsible For Container Securing On Board Ships?

Container lashing, the process of securing containers together on board a ship, is one of the greatest areas of risk in the marine cargo handling sector. It is therefore a task that requires a great deal of expertise and because of the expertise required, the shipowner contracts stevedores to carry out lashing and de-lashing jobs in port. The stevedores might or might not be employees of the container terminal where the vessel berths.

Regulations stipulate ships carry a cargo securing manual that contains instructions on how cargo should be secured in accordance with class standards. Because the approval of the arrangements in the manual presupposes the master uses good seamanship to lessen the forces operating on the cargo stowage arrangements, the master thus retains the ultimate responsibility for securing containers on his/her ship.

The container Lashing is regularly checked by the ship’s crew during the voyage to avoid any type of accidents because of improper lashing. The Shipmaster through the Chief Officer of the ship is, however, responsible for the safe stowage of the containers on ships.

Container Lashing Equipment

Container lashing equipment is used to keep cargo containers in place while they are being transported. Regulations stipulate that all container lashing equipment be approved and listed in the Cargo Securing Manual. There are a few different containers securing equipment, but the most common are twistlocks and lashing bars.

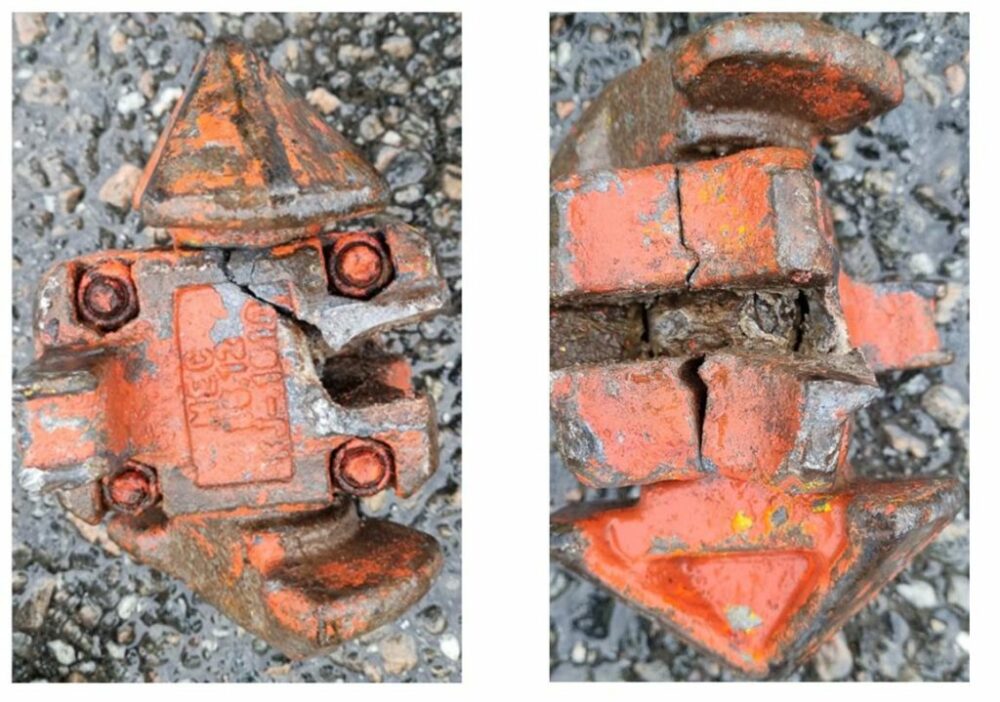

Twistlocks

Twistlocks are mechanical devices that are used to secure shipping containers to the deck of a ship or other cargo transport. They are inserted into sockets on the corners of the container and twisted to lock them in place. There are several different types of twistlocks, each with its own specific function and application.

When using twistlock, try to insert the twist locks into the bottom holes of the four bottom corners of the container before pushing the handle Twist the mushroom head 90 degrees to lock the container. There are two major types of twist locks: manual and semi-automatic.

What is the difference between manual and semi-automatic twistlocks?

Manual twistlocks and semi-automatic twistlocks are two different types of twistlocks used to secure shipping containers to the deck of a ship or other cargo transport. The main difference between the two is in the way they are operated.

Manual twistlocks are operated by hand, meaning they require manual labor to insert and twist the twistlocks into the sockets on the corners of the container to secure it in place. This can be done by a worker using a twisting wrench or a similar tool. They are commonly used in smaller ports or ships where the cargo handling capacity is lower.

Semi-automatic twistlocks, on the other hand, are operated using a machine or mechanical assistance, which reduces the amount of manual labor required. The twistlocks are inserted into the sockets on the corners of the container using a machine, and then locked into place using a handle or lever. This allows for faster and more efficient loading and unloading of containers. They are commonly used in larger ports or ships where the cargo handling capacity is higher.

It’s worth mentioning that, semi-automatic twistlocks can be further divided into two types: hydraulic and mechanical. The hydraulic twistlock uses hydraulic power to insert and lock the twistlock in place, while the mechanical twistlock uses a mechanical lever or handle to insert and lock the twistlock in place.

Lashing Rods

The lashing rods are used to secure the container stacks to the ship. Normally it is the second and third tiers that are lashed. The process uses short rods of 2500 mm in length and long rods of 4500 to 5000 mm, both with a hook with a swivel at one end and a turnbuckle at the other end.

The hook goes into the hole on the container casting and the other end with the turnbuckle is secured to a d ring welded onto the deck. For higher stacks, the turnbuckles are attached to the lashing bridges.

Container Bridge Fittings

Container bridge fittings are specialized equipment used to secure shipping containers to the deck of a ship or other cargo transport. They are also known as lashing bridges and are placed over the top of the containers to secure them in place.

The container bridge fittings typically consist of two main parts: the bridge and the lashing gear. The bridge is a metal structure that sits on top of the container, and the lashing gear is used to secure the container to the bridge. The lashing gear typically consists of turnbuckles, lashing rods, or other tensioning devices that are used to apply tension to the lashing gear and secure the container to the bridge.

Container bridge fittings are used in situations where the ship is not equipped with twistlocks or other types of container securing equipment. They are also used when the containers being loaded onto the ship are not equipped with corner castings or other features that would allow them to be secured using twistlocks or other types of container securing equipment.

In addition to being used on ships, container bridge fittings can also be used on other types of cargo transport, such as railcars or trucks. They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport.

It’s worth noting that, container bridge fittings are less common than twistlocks or lashing rods, and are typically used in specific situations or when other types of container securing equipment are not available.

Lashing turnbuckles

Container lashing turnbuckles are specialized equipment used to secure shipping containers to the deck of a ship or other cargo transport. They are also known as tensioning devices and used in conjunction with other lashing equipment such as lashing rods, lashing bridges, and D-rings.

A container lashing turnbuckle is a metal device that consists of a long rod with a threaded end and a handle or lever. The rod is inserted through holes in the container’s corner castings and then tightened using the handle or lever. This applies tension to the lashing equipment and secures the container to the ship’s deck.

Turnbuckles are typically used in conjunction with other types of lashing equipment, such as lashing rods or D-rings. The turnbuckles are used to apply tension to the lashing equipment and secure the container to the ship’s deck, while the lashing rods or D-rings are used to physically connect the container to the ship’s deck.

They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport. The turnbuckles are typically made of durable materials such as steel or aluminum, and are designed to withstand the rigors of sea travel and the forces exerted on the containers during transport.

It’s important to note that, container lashing turnbuckles are used in conjunction with other lashing equipment, and are not designed to be used alone. They also need to be regularly checked, adjusted and maintained to ensure that the container stays secure during transport.

Container Stacking Cones

Container stacking cones, also known as stacking cones or stacking chocks, are specialized equipment used to secure shipping containers to the deck of a ship or other cargo transport. They are used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges to provide additional stability and security for the containers.

A container stacking cone is a cone-shaped device that is placed between the containers to prevent them from shifting or sliding during transport. They are typically made of durable materials such as rubber or plastic and are designed to withstand the rigors of sea travel and the forces exerted on the containers during transport.

Container stacking cones are typically used in situations where the containers are stacked on top of each other and need additional support to prevent them from shifting or sliding. They are typically used on ships that transport large numbers of containers or containers that are carrying particularly heavy or sensitive cargo.

Stacking cones are placed between the containers, and typically used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges, to provide additional stability and security for the containers. They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport.

Container Midlocks

Container midlocks, also known as intermediate locks, are specialized equipment used to secure shipping containers to the deck of a ship or other cargo transport. They are used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges.

A container midlock is a mechanical device that is used to secure the middle of a container to the ship’s deck. It typically consists of a locking mechanism that is inserted into a socket on the container and tightened to secure the container in place.

Midlocks are used in situations where standard twistlocks, which are designed to secure the corners of the container, are not sufficient to keep the container stable during transport. They are typically used on ships that transport large, heavy containers or containers that are carrying particularly sensitive or valuable cargo.

Midlocks are typically used in conjunction with other types of lashing equipment, such as twistlocks or lashing rods, to provide additional stability and security for the containers. They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport.

Lashing Pots & Securing Points

Lashing pots and securing points are specialized equipment used to secure shipping containers to the deck of a ship or other cargo transport. They are used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges to provide additional stability and security for the containers.

A lashing pot is a circular or cylindrical metal pot that is typically welded to the ship’s deck. It is used to secure the container to the ship by providing an anchor point for lashing equipment such as lashing rods or turnbuckles.

A securing point is an anchor point on the ship’s deck which is used to secure the container to the ship. It can be a D-ring, a lashing point or other type of anchor point.

Lashing pots and securing points are typically used in situations where the containers are stacked on top of each other and need additional support to prevent them from shifting or sliding. They are typically used on ships that transport large numbers of containers or containers that are carrying particularly heavy or sensitive cargo.

They are commonly used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges, to provide additional stability and security for the containers. They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport.

Elephants Foot

An elephants foot is a specialized piece of equipment used in container lashing on ships. It is a device that is placed between the containers and the ship’s deck to provide additional stability and prevent the containers from shifting during transport.

An elephants foot typically consists of a rubber or plastic base with a metal rod or bar that extends upward. The base of the elephant’s foot is placed between the container and the ship’s deck, and the metal rod or bar is inserted into a socket or hole on the container. The elephant’s foot is then tightened to secure the container in place and prevent it from shifting during transport.

Elephants feet are typically used in situations where the containers are stacked on top of each other and need additional support to prevent them from shifting or sliding. They are typically used on ships that transport large numbers of containers or containers that are carrying particularly heavy or sensitive cargo.

They are commonly used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges, to provide additional stability and security for the containers. They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport.

Container D Rings

Container D-rings, also known as D-rings or D-shaped rings, are specialized equipment used to secure shipping containers to the deck of a ship or other cargo transport. They are used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges.

A container D-ring is a D-shaped metal ring that is welded to the ship’s deck. It is used to secure the container to the ship by providing an anchor point for lashing equipment such as lashing rods or turnbuckles. The lashing equipment is passed through the D-ring and then tightened to secure the container in place.

D-rings are typically used in situations where the containers are stacked on top of each other and need additional support to prevent them from shifting or sliding. They are typically used on ships that transport large numbers of containers or containers that are carrying particularly heavy or sensitive cargo.

D-rings are commonly used in conjunction with other lashing equipment such as twistlocks, lashing rods, and lashing bridges, to provide additional stability and security for the containers. They are commonly used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport.

Twistlock Operation Rods

Twistlock operation rods, also known as twistlock handles or twistlock wrenches, are specialized tools used to operate twistlocks, which are mechanical devices used to secure shipping containers to the deck of a ship or other cargo transport.

A twistlock operation rod is a long metal rod that is used to insert and lock twistlocks into place. It typically has a handle on one end and a socket or adapter on the other end that is designed to fit into the twistlock. The operator uses the handle to insert the twistlock into the container’s corner casting, and then turns the handle to lock the twistlock into place.

Twistlock operation rods are typically used in ports or other cargo handling facilities where containers are loaded and unloaded from ships or other cargo transport. They are commonly used by cargo handlers and stevedores to secure the containers to the ship’s deck.

Conclusion

As boundaries of mega-sized containerships get pushed, a continual focus on preventing container lashing failure becomes even more important. There are now Ultra Large Container Vessels (ULCVs)- the very largest container vessels, capable of carrying almost 24,000 TEUs in service and capable of loading 11 levels on deck.

These ships belong to EVER A-class container ships built by two shipyards for Evergreen Marine Corporations. The first launched ship was Ever Alot and became the largest container ship in the world holding this title for over 2 years.

As a result, the integrity and reliability of container lashing have become of much more concern to ship officers because of higher deck loads, which require more stringent lashing arrangements.

It is therefore critical that ship officers be aware of new lashing arrangements and technologies being deployed such as the RSCS+ enhanced Route Specific Container Stowage that permits heavier and higher deck loads and/or less strict lashing arrangements at certain stowage locations depending on the routes and seasons the ship trades.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply