Fuels are the lifeblood of marine diesel engines. With fuel problems that may occur on board, cargo and shipments will not be delivered on time, which we must prevent to keep the business running.

That’s why it is very important that the correct grade of fuel is supplied to the ship. Furthermore, it is imperative for it to be maintained in a clean condition, and temperature and pressure must be met accordingly to ensure the maximum efficiency of the engine.

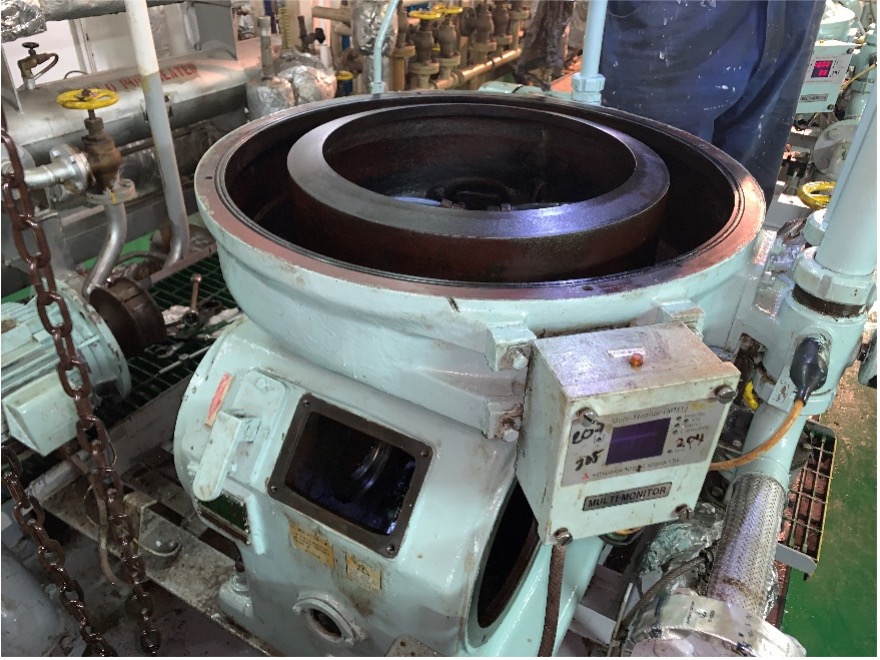

A fuel oil purifier is a device used onboard ships to remove sediments, sludges, and water content on HFO. This is achieved by using an electric motor as means of the prime mover to rotate the bowl at a very high speed, thus generating a centrifugal force for separating two liquids with different densities.

As the bowl inside rotates at high speed, the sediments, sludges, and some particles that are mixed during the refining process will be pushed outside the disc, and the clean fuel that is produced will be pushed upward the center bore of the discs (due to centrifugal force) exiting through the outlet pipe.

The produced purified fuel will be sent to the fuel oil service tanks and later will be used for consumption by the main engine and generators.

Clean fuels can be attained through the use of purifiers onboard, but first of all, let’s take review the parts and functions of fuel oil purifiers in order to know how it operates to produce clean fuels.

Fuel Oil Purifier Parts And Functions

Fuel oil purifier consists of the following parts and groups of parts.

- Frame and cover assembly

This group constitutes basically covers, pipes, frames, etc. Here we can find the labels of the purifiers, which includes their specifications, brand, motor capacity, and safety reminders.

- Vertical shaft section

This section rotates the bowl which is mounted on its top. The vertical shaft is incorporated by a pinion gear which increases the revolution given by the horizontal shaft, thus giving a higher speed to rotate the bowl. In order for this to rotate stably, it is supported by upper spring and leaf springs radially incorporated at 6 points on the upper bearing section and lower springs in the lower bearing section.

Along with this, the water chamber is part of the vertical shaft section. The water chamber is the one responsible for delivering water inside the bowl to open or close the main cylinder for it to discharge accumulated sludge during the operation.

It also supplies sealing water along with the replacement water inside the bowl.

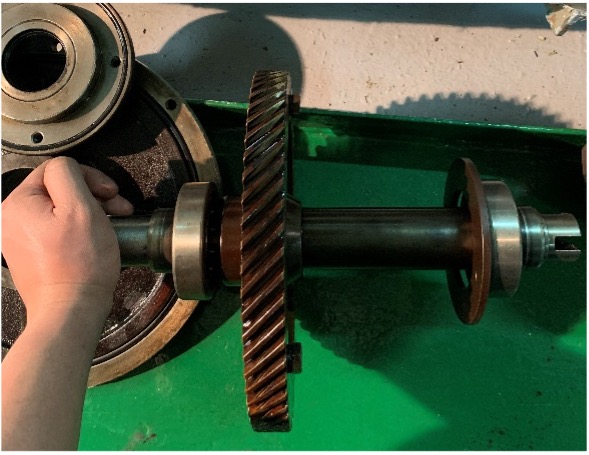

- Horizontal shaft section

The horizontal shaft is rotated directly by the motor with the help of the friction clutch. However, some purifier uses belts instead of horizontal shafts.

A friction clutch is provided for accelerating the purifier gently, thereby preventing the motor from overloading. The shaft of the motor is equipped with a friction boss, where the friction clutch is attached, while the horizontal shaft is provided with a friction pulley.

As the motor starts, it instantly turns at a critical speed, thus pushing the friction clutch outward via centrifugal force and pressing it to the internal surface of the friction pulley. The friction clutch slides through the friction pulley and gently rotates the friction pulley along with the horizontal shaft where it is connected.

The horizontal shaft is supported by two ball bearings and between them- the spiral gear. The spiral gear is directly coupled to the pinion gear of the vertical shaft to transmit the power and rotate it.

- Bowl assembly

The bowl section consists of the bowl body, main cylinder, pilot valve, disc, bowl hood, and nut. The bowl incorporates a separation chamber composed of discs and a distributor, which distributes feed liquid from the bowl inlet to the separation chamber uniformly.

The main cylinder slides vertically with the help of water pressure delivered by the water chamber to discharge sludge and other sediments that are accumulated on the inner wall of the bowl during operation.

Moreover, there are pilot valve assemblies located outside the bowl. They are used for controlling the movements of the main cylinder, either sliding for closing or opening.

Furthermore, the fuel oil is introduced through the feed liquid inlet pipe, then through the distributor, up until the separation chamber and passes through the gaps between discs. During this period, solids, sludges, and water are separated as the bowl rotates generating a centrifugal force.

Purified oil produced after the separation is continually delivered outside by the centripetal pump (light liquid impeller) located on the top of the bowl. Meanwhile, separated water is continuously discharged outside through the heavy liquid impeller.

Fuel Oil Purifier Operation On Ships

The dirty heavy fuel oil that is delivered onboard must be purified before it is used. After receiving the bunker, it is stored in fuel oil storage tanks before it is transferred to fuel oil settling tanks.

From settling tanks, it is then delivered to the purifying system to remove the sediments and sludges.

During the purifying process, the fuel inside the settling tank is suctioned by the HFO purifier feed pump, passing it to an oil heater to increase its temperature before it is fed to the purifier.

Fuel oil purifiers are equipped with a temperature control valve (TCV) to regulate the temperature of the fuel inside the oil heater as it goes to the purifier.

However, not all the fuel will enter the purifier because the feed of the purifier is controlled at the inlet valve to keep the produced fuel at range (liters/hour), depending on the ship’s consumption and case. The excess fuel will be delivered back to the settling tank.

Once it is inside the purifier, it goes through the separation zone which is done by the distributor. While the separation is ongoing, the heavy liquid with solids and sediments goes to the outer periphery of the bowl with the help of the centrifugal force, and light liquid (clean fuel) moves inside the center bore of the discs and is discharged by means of the light liquid impeller.

The accumulated sludges are discharged with the help of the water-supplying device and the pilot valve of the bowl. The water-supplying device supplies water to operate the pilot valve to open the bowl and closes the bowl as well by filling the water in order to lift the main cylinder.

Moreover, clean fuel is delivered to the service tank and will be stored for further consumption by the ship main engine and generators onboard.

Why Is Fuel Oil Treatment Necessary?

Heavy fuel oil supplied onboard is a heavy residue from cracking most of everything from crude oil. It is mixed with a mechanical catalyst and heated to produce lighter gas oils during the refining process.

Unfortunately, these sediments and sludges may block the filter if not purified and treated and may reduce the pressure needed to sustain proper combustion.

Some sediments may be so small that they may pass the filter and into the injectors of the engine, resulting in blocking the atomizer and reducing the efficiency of the engine performance.

Why Does A Heavy Fuel Oil Purifier Need Heating?

Heating plays a vital role in treating the fuel oil supplied onboard. It helps for the proper separation of water from fuel inside the purifiers as well as ensures a smooth pumping of the fuel oil at different processes and consumption.

Moreover, maintaining the desired temperature for the viscosity of the fuel helps proper combustion of fuel inside the combustion chamber, thus giving maximum efficiency to the engine.

Remember, fuels supplied onboard are residues from refining crude oil so it is necessary to make a routine inspection and maintenance of the purifier in order to provide purified fuels for the consumption of the engines.

Furthermore, maintain desired temperature range for the fuel to be able to pump them accordingly and avoid any problems.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply