Ever wonder how the ship maintains its desired speed and course to meet both the charterer’s and the owner’s timetable? Each ship is composed of the main propulsion engine and auxiliary engines which hand-in-hand help each other to sustain the desired temperatures, pressure, and speed that are needed to keep the ship running.

The maritime industry has been serving as the backbone of the world economy. Thus modern ships are equipped with main engines and auxiliary engines to deliver cargo and shipments faster and with no delay. However, we need also to attain the knowledge and skills to make the most precise and accurate maintenance needed for the engines to make it on schedule.

Kinds of Engines as Main Propulsion system

The engine that is responsible for running the ship is the main engine that serves as the one that gives the main propulsion for the ship. It is connected to the propeller with the help of the intermediate shaft. It can go forwards and backward depending on what order is given to the engine. Moreover, as technology advances, mankind has invented kinds of main propulsion systems for ships.

Direct Drive Propulsion System

Most of the ships use this kind of system. This propulsion system has a very basic engine-propeller arrangement for the ship and is an invariable choice for low-speed diesel engines. Maneuvering of the ship is done by changing the directions of the propeller along with the speed of the main engine.

Geared Drive Propulsion System

Nowadays, ship owners along with their shipbuilders generally use this. Its function is to reduce the number of revolutions from the output of the engine in such a way that the system can give maximum propeller efficiency. Also, pitch propellers are added to make reversing done easily.

Electrical Drive Propulsion System

Most electrical drives consist of medium or high-speed diesel engines as their means of the prime mover. The only disadvantage of this kind of system is that it is kind of expensive when compared to geared drive. This is mainly because of lower mechanical efficiency and higher consumption of fuel.

What Kinds Of Engines Are Used On Ships?

Generally, that are two types of engines that are used on ships- a two-stroke diesel engine and a four-stroke diesel engine. Two-stroke diesel engines are low-speed engines and are used mainly for

ship’s propulsion, while four-stroke engines are high-speed engines and are typically used as a prime mover for alternators to produce electrical energy onboard. When it comes to power, we rely on two-stroke engines, because propulsion efficiency, power, and torque are mostly greater on low-speed engines which are likely needed by the ship.

Meanwhile, a four-stroke engine makes two revolutions of its crankshaft between one power stroke, meaning it can have twice the rpm produced, and the alternator needs that to produce large amounts of electrical power.

Why Two-Stroke Engines Are Used On Ships?

Two-stroke engines generate more power output, because it has 1 power stroke in 2 strokes, unlike four-stroke engines, which only generate 1 power stroke in four strokes or two revolutions. Aside from

the adequate power and torque that it can produce, two-strokes are used on ships simply because they can move in a reverse manner, ahead or astern. But take note, you can only change the rotation of this engine by stopping it first, then once it stops, you can crank it on the rotation that you need to use.

Since the shaft and the propeller is connected to this engine directly, you can just shift to ahead or stern after stopping. The strokes of this engine (intake/compression, power/exhaust) made the rotation possible to be reversed because there is no restriction for any opening of the intake and exhaust valve, unlike the four-stroke engine.

Furthermore, as stated before, since they are low-speed engines, there’s no need to install a reduction gear or speed reduction arrangement, as required for the four-stroke engines.

What about the four-stroke engine? Four-stroke engines can’t move in reverse because they have intake and exhaust valves that open according to the stages of stroke (intake, compression, power, and exhaust). Let’s say we try to run in reverse, the exhaust will open while needing intake air, which surely it can’t supply because the intake valve is in charge of giving air for compression, thus making the engine unable to run.

What Machineries Support The Main Engine?

The main engine onboard is incapable of sustaining itself, that’s why we have supporting machinery for them to continue running. Supporting machinery onboard is called auxiliary machinery and is composed of generators, boilers, purifiers, compressors, freshwater generators, and steering gear. Let’s take a closer look at each of them.

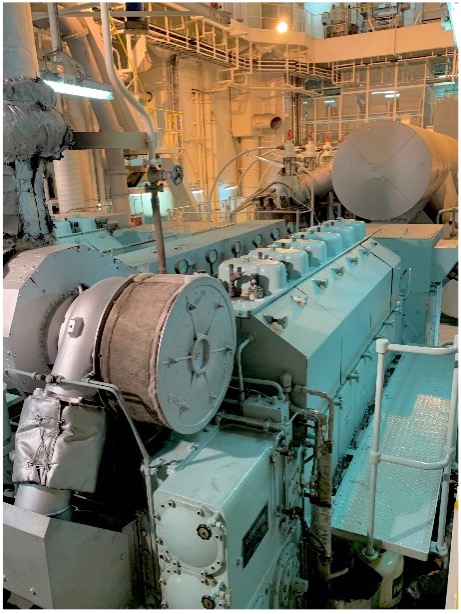

Generators

This machinery is very important to the ship. Generators are high-speed diesel engines that are connected to an alternator its function is mainly to supply electrical energy on board. Each ship consists of 2-4 generators, which are enough to give the desired power supply needed for the ship’s voyage and its operation.

Boilers

Steam production is very essential onboard. That’s why boilers are used to provide steam production to maintain the desired fuel and water temperature needed by the engines. Steam is produced by applying heat to water. It helps adjust the viscosity of the fuel, which is very important for the proper combustion of the engine.

Steam supplied by boilers is distributed thru tracing lines, heaters, and pipes, which are covered mainly by insulation materials because they tend to become hot and might cause a burning sensation if accidentally touched on the skin.

There are also what we call Composite Boilers, these boilers can run with two systems, either by utilizing the exhaust of the main engine or by the conventional oil firing and burning to create steam.

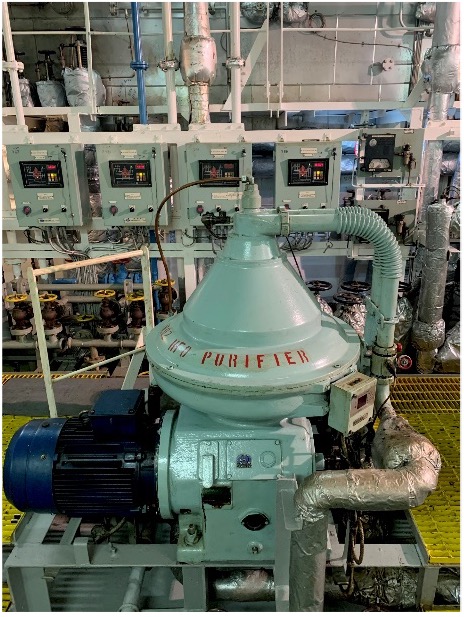

Fuel Oil Purifiers

Fuel or bunkers delivered onboard needs to be purified due to the minerals mixed with them during a refining process. Along with that, purifiers are introduced to remove the sediments and sludge. Purifiers operate a centrifugal force to separate dirt from the clean fuel.

As the bowl inside rotates at high revolutions, the sediments will be pushed outside the disc, and the clean fuel that is produced will be pushed upward the center bore of the discs exiting through the outlet pipe and then will be used for consumption of the main engine and generators.

Compressors

These types of machinery compress air and then deliver it to the air reservoir. They start and stop at a certain pressure. Now, the compressed air inside the reservoir will be used for starting the main engine and generator.

Also, the compressed air will be used to blow the ship’s whistle, automation, instrument various pieces of machinery, or operation of quick closing valves.

Fresh water generator

The sea is obviously abundant in water, and it’s our source of fresh water on board. The freshwater generator generates distilled water by using an ejector which creates a vacuum inside, and in that state, water will start to boil around 40-50 degrees centigrade by using the jacket cooling water of the main engine.

After it is boiled and evaporates, it will be filtered by a demister and then will be condensed by seawater. The distilled water that is produced will be delivered to the freshwater tanks which will be used for general purposes like main engine cooling and accommodation use.

Steering Gear

This machinery is provided on ships to turn the ship left (port side) or right (starboard side) during sailing or maneuvering according to the commands given from the navigational bridge by the steering wheel or by internal telecom.

All ships are equipped with main steering gear and auxiliary or emergency steering gear. Modern ships use kinds of means to operate the steering gear, these are namely- fully hydraulic type, electro-hydraulic type, and fully electric type.

All these auxiliary pieces of machinery play a vital role in the ship’s system. Without one or the other, problems may arise and complications may be unsustainable in the long run. That’s why proper care is needed for them to last.

Which Companies Make Ship Engines?

There are three leading companies that manufacture the engines for ships:

- Wärtsilä of Finland

- MAN Energy Solutions of Germany

- Mitsubishi Heavy Industries of Japan.

These companies still thrive to improve the engines they make as the years pass, for their challenge is to produce cleaner and more efficient types of engines that the environment needs.

What Is The Biggest Ship Engine?

Who do you think made the breakthrough to create the biggest engine? Well, Wartsila of Finland won its title for introducing a massive 14-cylinder low-speed engine last 2006.

The 14-cylinder Wartsila RT-flex96 engine is not only the largest but is also the most powerful engine with an output of 80,080 kW at 102 rpm. This engine is a two-stroke, turbocharged diesel engine made and designed to power large container ships.

What Kind Of Engine Does A Cruise Ship Have?

Mostly, cruise ships are using four-stroke engines to drive their generators and generate enough electricity to supply their voyage, hotel rooms, and restaurants. Without it, they would only be like floating hotels in the middle of the ocean.

Apparently, their means of propulsion are electrically-driven because it is powered by their generators. Azipods are the new cruise ship propulsion systems. Azipods are driven by an electrically powered propulsion motor that controls the rotation of the propeller. They provide better maneuverability, reduce bad emissions, and maximize speed.

What makes it unique is that it can turn in all directions (360 degrees) with or without a rudder, thus providing thrust in any direction needed. It is said to be a combination of both steering and propulsion systems.

Furthermore, azipods’ speed is controlled by a frequency controller. This is used to change the frequency that is supplied by the supply transformers so that the rotating motor speed can be controlled.

What Engines Do Container Ships Use?

Container ships use a low-speed, two-stroke diesel engine as their means of prime mover for their propulsion system in order to transport goods around the globe.

Two-stroke engines as stated before, produce more power and they have a high power-to-weight ratio which is beneficial for the ship for it can carry more cargoes to transport.

Also, the other reason why they choose two-stroke engines as their prime mover for propulsion is because of their reversing capabilities. Meanwhile, as for their source of electricity, they use a four-stroke diesel engine to drive their alternators and produce electrical power for the ship to use.

There are common types of propulsion that naval ships use, these are diesel propulsion, nuclear propulsion, and gas turbine propulsion. All warships and naval battleships require high-performance, low-maintenance, efficient, and durable propulsion systems. For they tend to go in and out on any unpredicted wars and exercises.

Diesel propulsion converts thermal forces into mechanical energy, allowing it to propel through water and it is also the most common type of ship propulsion.

Aside from this, they utilize also use nuclear-powered propulsion, where they use complex systems along with nuclear fissions and water reactors to fuel the vessel. Furthermore, nuclear reactors are also used to generate electricity for the ship.

Meanwhile, some naval warships use gas turbines as their means of propulsion. It compresses air and with the right ratio, it is mixed with fuel and burned at extremely high temperatures thus creating hot gasses. Hot gasses are used to spin the turbines, they glide through the blades causing them to spin quickly.

Outline

Furthermore, all these types of machinery equipped on the ship must be checked and inspected mostly on a day-to-day basis. That’s why it is essential to learn and study them before the responsibility is given to us by the owner. So to avoid delays in their shipments and cargoes, we need to maintain them to their best to give the maximum output needed.

So, we have learned that the main engine is mostly a two-stroke engine because of its reversing capabilities and can produce efficient power and torque needed for the ship’s propulsion. Moreover, two-stroke diesel engines are widely used by most ships as their prime mover for their propulsion system while four-stroke diesel engines are used commonly for driving the alternator to create electrical energy.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply