International law requires ships to carry documents and certificates attesting to their compliance with various international conventions. The documents and certificates, as well as the equipment and systems they attest to, are inspected periodically to ensure the provisions of the laws are being complied with.

A survey is therefore an inspection of a system or equipment to determine and ensure that it is suitable for its intended purpose.

Ship surveys are carried out by an independent third party and are critical to ensuring the safe and efficient operation of ships. The verification of the integrity of a system, or equipment on board a ship, by an independent third party, is vital from the safety aspects, as it potentially removes the probability of bias.

The International Maritime Organization (IMO) has enacted legally binding standards for the protection of ships through the implementation of a number of conventions.

For example, the International Convention for the Safety of Life at Sea (SOLAS) outlines in chapter I of its annex the specific standards that must be met in order for ships to be surveyed and certified. In resolution A.1120 (30), the IMO has compiled the scope and scheme of all ship safety surveys.

Ship Survey Types

Surveys are carried out either by Port States, Flag states, or organizations they empower to carry out the surveys on their behalf. The following are the types of surveys carried out on ships:

Initial Survey of the Ship

An initial survey is a comprehensive examination of the condition of a vessel and its compliance with national and international safety requirements. It is usually carried out by surveyors from classification societies on behalf of the vessel’s flag state before the equipment or system is put into operation.

The survey includes an assessment of the vessel’s structural integrity, safety equipment and systems, and compliance with the SOLAS convention.

The initial survey should consist of the following:

- a review of the plans, diagrams, specifications, calculations, and any other forms of technical paperwork to ensure that the building, its machinery, and its equipment are in accordance with the requirements of the specific certificate;

- An inspection of the structure, machinery, and equipment to ensure that the materials, scantling, construction, and arrangements, as appropriate, are in accordance with the approved plans, diagrams, specifications, calculations, and other technical documentation; an examination to ensure that the workmanship and installation are satisfactory in all respects.

- a verification that all the certificates, record books, operational manuals, and other instructions and documents demanded by the prerequisites for the specific certificate have been brought aboard the vessel.

- an analysis of the blueprints and sketches.

A request for an initial survey should be supported by plans and designs, as required by Administration or Class Society, depending on the circumstance, as well as the following items:

- details regarding the ship itself;

- any exemptions that are requested;

- any further unique requirements.

Periodical Survey

A Periodical survey of a ship is the practice of inspecting a ship periodically to ensure it is seaworthy and compliant with all regulations.

It involves the inspection of the items relating to the particular certificate to ensure that they are in satisfactory condition and fit for the service for which the ship is intended.

These surveys are typically conducted by third-party organizations on behalf of the ship’s owner or operator.

Renewal Survey

Renewals surveys are conducted every five years and are required in order to renew the vessel’s certificate of documentation. The survey includes a hull and machinery inspection, as well as an examination of the vessel’s cargo gear and other equipment.

The purpose of the survey is to ensure that the vessel is fit for its intended purpose and that it meets all applicable safety standards. The renewal survey process is as per the periodical survey but leads to the issue of a new certificate.

Intermediate Survey

An intermediate survey is carried out during the half-year validity of the certificate. The purpose of an intermediate survey is to ensure that the vessel is still in compliance with all the applicable regulations and that it is safe to continue operating.

During an intermediate survey a number of specified items. will be thoroughly examined by the surveyors. They will check all the critical systems and components of the vessel, as well as its overall condition.

Annual Survey

An annual survey is an inspection that is carried out once a year on a ship. This inspection is carried out to ensure that the ship is in compliance with all the necessary safety regulations.

The survey covers a wide range of items, from the condition of the hull to the functioning of the engine. It involves a general inspection of the items relating to the particular certificate to ensure that they have been maintained and remain satisfactory for the service for which the ship is intended.

Pre-purchase Survey

A Pre-purchase Survey is an extensive inspection of a vessel that is typically conducted before a buyer finalizes a purchase. This survey is crucial for assessing the overall condition and value of the ship.

Pre-purchase Survey involves a thorough examination of the ship’s structure, machinery, equipment, and overall maintenance. The surveyor checks for any signs of damage, wear, or necessary repairs, and evaluates the ship’s seaworthiness.

The findings help the potential buyer make an informed decision about the purchase, understand the vessel’s current state, and anticipate any future maintenance or repair needs. Essentially, it’s a detailed health check of the ship before buying it.

Dry Docking Survey

A Dry Docking Survey is a comprehensive examination of a ship that is carried out when the vessel is placed in a dry dock. During this survey, parts of the ship that are usually underwater, such as the hull, propellers, rudders, and other related structures, are thoroughly inspected.

The survey allows for close inspection of areas that are not easily accessible when the ship is afloat. It is crucial for identifying any damage, corrosion, or necessary repairs that might not be visible during regular operations.

This survey is essential for maintaining the structural integrity and safety of the vessel.

On/Off-Hire Condition and Bunker Survey

An On/Off-Hire Condition and Bunker Survey is conducted when a vessel is chartered (rented). There are two main components to this survey:

- Condition Survey: This part assesses the physical condition of the vessel at the time of chartering (on-hire) and when it is returned (off-hire). It documents the vessel’s overall state, including any damages or defects, ensuring that any changes in the condition during the charter period are noted and accounted for.

- Bunker Survey: This survey measures the quantity of bunker fuel (ship fuel) on board at the start (on-hire) and end (off-hire) of the charter period. It’s crucial for calculating fuel consumption during the charter and for financial settlements between the charterer and the ship owner.

Surveys for Ship Recycling

Before a ship undergoes recycling, specific surveys are conducted to ensure the process is done safely and in an environmentally responsible manner. These surveys include:

- Inventory of Hazardous Materials (IHM) Survey: This survey identifies and documents all hazardous materials on the ship. It’s crucial for planning the safe and environmentally sound recycling of the vessel.

- Pre-cleaning Survey: This survey assesses the need for cleaning the ship of operational wastes and possibly hazardous substances like oils, chemicals, and sludge before recycling.

- Final Survey: Conducted just before recycling, this survey confirms that the vessel is ready for recycling in accordance with all relevant safety and environmental regulations.

These surveys are essential to comply with international regulations, such as the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, which sets global standards for safe and eco-friendly ship recycling.

Additional Survey

Special surveys are inspections, either general or partial according to the circumstances, to be made after a repair resulting from casualty investigations or whenever any important repairs or renewals are made. They are inspections that are conducted to ensure that the vessel is safe and fit for operation.

Special surveys can typically also be required for vessels over 20 years old, deemed to be high-risk, or have a history of accidents or incidents. During a special survey, the surveyor will conduct a thorough examination of the vessel. This will include an inspection of the hull, superstructure, machinery, and equipment. The surveyor might also interview the crew and review the vessel’s maintenance records.

The Harmonized System of Ship Survey.

In order to cover the survey and certification requirements of SOLAS, 1974, the Loadline Convention, 1966, MARPOL 73/78, the IBC Code, the Code for the Construction and Equipment of Ships Carrying Dangerous Chemicals in Bulk (BCH Code), and the Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk, (IGC Code)., the IMO established the “Harmonized System of Surveys and Certification” (IMO Resolution A746 (18)) on February 3, 2000

The provisions of the conventions call for the issuance of certificates to demonstrate that specifications have been satisfied, and this must be done through surveys that might require the ship to be taken out of service for a number of days.

A ship shouldn’t have to enter a port or a repair yard again to conduct a survey required by one convention right after performing the same task in connection with another instrument thanks to the harmonized system, which will solve the problems brought on by survey dates and intervals that don’t coincide with one another.

The harmonized system offers the following:

- a standard survey interval of one year based on initial, annual, intermediate, periodic, and renewal surveys as necessary;

- a plan for allowing the necessary flexibility for the execution of each survey, with the proviso that the renewal survey may be finished within three months of the current certificate’s expiration date without reducing the validity of the certificate;

- a five-year maximum validity period for all certificates for cargo ships;

- a Passenger Ship Safety Certificate with a maximum validity duration of 12 months;

- a procedure enabling certificates to be extended for a maximum of three months (or one month for ships on short journeys) to allow a ship to complete its journey;

- After an extension has been granted, the new certificate’s validity period will begin on the date that the old certificate would have expired without the extension.

Current Survey Practices

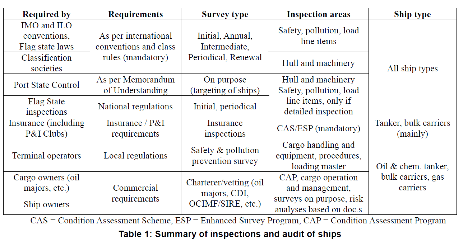

The ship’s inspection system currently has several participants and consists of a mandatory part (statutory and class) and a non-mandatory part (industry-driven). The mandatory part, based on the international legal framework which was normally to be enforced by the flag and Port states, is nowadays more and more being performed by recognized organizations.

From “A Review of Ship Survey Practices and Marine casualties Partly Due to Aging Effects.” by Rizzo and Nigro, 2008, Proceedings of the ASME 27th International Conference on Offshore Mechanics and Arctic Engineering, P. 10

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply