Supramax bulk carriers have become an essential part of the global shipping industry. These massive vessels are known for their impressive carrying capacity, versatility, and efficiency.

In this article, we’ll explore the key features of these ships, discuss their specifications and how they compare to other types of carriers like the Ultramax, and take a look at some of the leading shipping companies like Pacific Basin that operate Supramax vessels.

The Supramax Carrier: Size and Specifications

A Supramax vessel typically ranges in size from 50,000 to 60,000 deadweight tonnage (DWT), making them larger than Panamax carriers but smaller than the largest bulk carriers. Some of the key specifications of a Supramax bulk carrier include:

- Length: 180-200 meters

- Beam: 32-35 meters

- Draft: 11-14 meters

These dimensions allow Supramax vessels to navigate through a variety of waterways, including those with shallower depths or narrower widths, such as the Panama Canal.

Supramax carriers are equipped with onboard cranes, making them “geared” vessels. This feature allows them to load and unload cargo in ports without the need for specialized equipment, adding to their versatility and reducing dependency on port infrastructure.

The Origin of the Term Supramax

The term “Supramax” is derived from the combination of the Latin prefix “supra-” and the word “max,” which is short for “maximum.” In this context, “supra-” means “above” or “beyond.” The term “Supramax” was coined to describe a class of bulk carriers that are larger than the Panamax vessels but smaller than Capesize vessels.

The Panamax vessels are designed to fit within the size limitations of the Panama Canal, and the term “Panamax” itself refers to the maximum size of a ship that can pass through the canal. Supramax vessels, being slightly larger than Panamax carriers, are not constrained by these size limitations, offering greater cargo-carrying capacity and more versatility in terms of the waterways they can navigate.

The term “Supramax” highlights that these vessels go beyond the maximum size constraints of Panamax ships, while still being smaller than the even larger Capesize vessels.

The Fuel Consumption of a Supramax Bulk Carrier

The fuel consumption of a Supramax bulk carrier can vary depending on factors such as the ship’s size, age, engine type, and speed at which it is traveling. However, on average, a Supramax vessel can consume between 25 and 35 metric tons of fuel per day while sailing at a typical speed of around 12-14 knots.

It is important to note that these figures are approximate and can be influenced by factors such as weather conditions, sea state, and the specific load being carried by ship. Additionally, technological advancements and improved energy efficiency measures, such as the use of scrubbers or slow steaming, can help reduce fuel consumption and the associated costs for ship operators.

Supramax Vessel Structure and Design

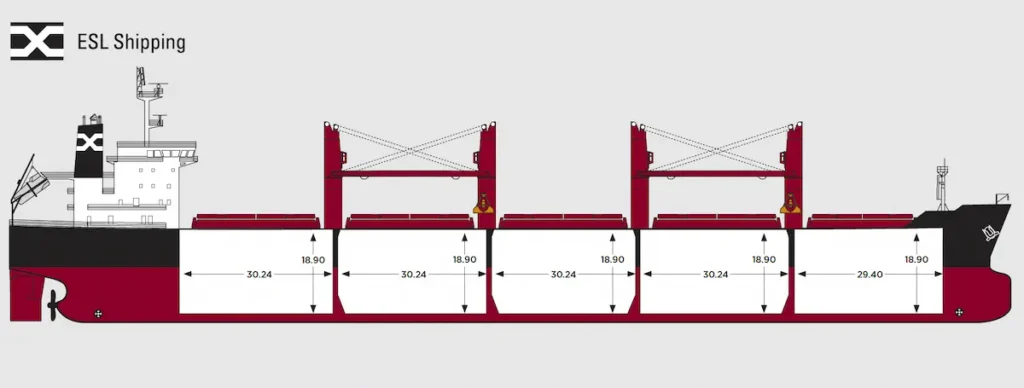

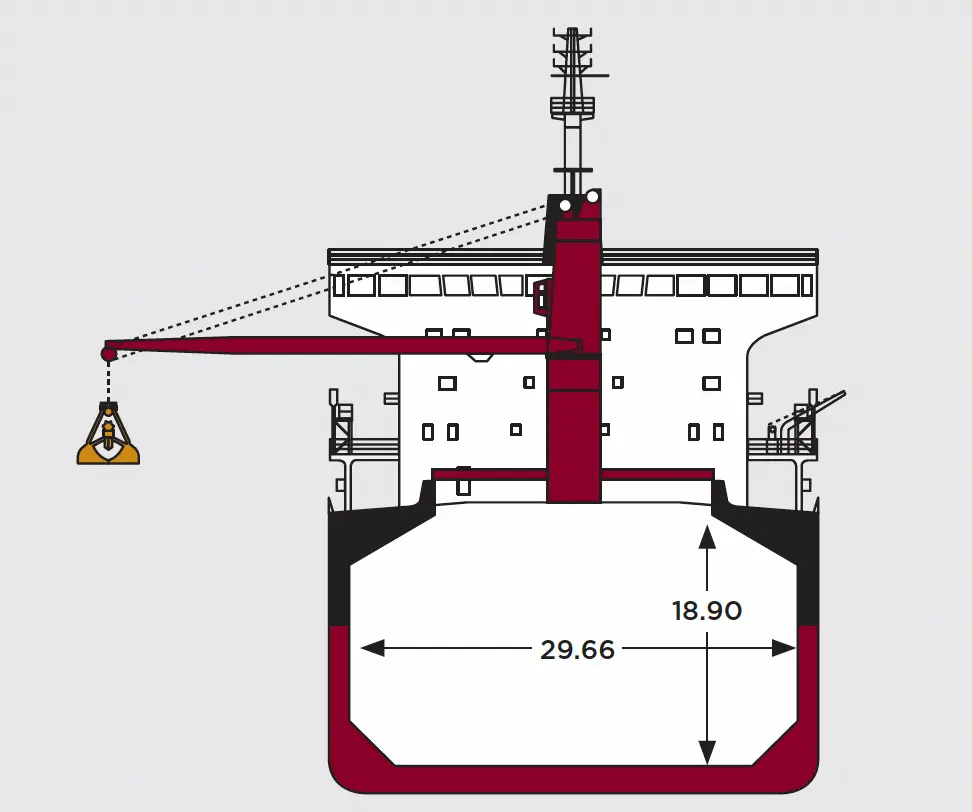

Supramax bulk carriers typically feature a superstructure at the stern, which accommodates crew quarters, machinery, equipment, and the bridge. The upper deck includes hatch covers and deck cranes, with around five watertight hatches on conventional vessels. Four deck cranes are usually present, offering an average lifting capacity of 30 tons and enabling efficient loading and unloading of cargo.

Modern Supramax vessels measure approximately 199 meters in length, 32 meters in beam, 12.2 meters in draft, and 18.8 meters in depth. The engine compartment houses the twin-stroke marine diesel engine, which powers a fixed-pitch propeller. The hull features a double bottom for increased stiffness and leakage prevention. Inwardly sloped hulls near the bilge prevent substance accumulation and provide ballast water storage.

Supramax Vessel Operations

Supramax vessels can accommodate crews of 10 to 30 individuals, depending on their size. The operational routes often depend on supply and demand, and these vessels can travel through most locks and canals, such as the Panama Canal and the Suez Canal. Turnaround times at ports can range from 12 hours for container vessels to 60 hours for Supramax vessels.

Loading and unloading processes are critical for Supramax vessels and can be carried out using gantry bins, deck cranes, or conveyor belt systems. Proper cargo placement and restraint are essential to prevent shifting during transit. Unloading cargo must be done carefully to avoid damage to the vessel or pier, and cargo shifts must be managed to prevent capsizing or splitting. Once unloaded, the holds must be thoroughly cleaned using high-power water jets and chemicals to prevent contamination and corrosion.

Supramax vs. Ultramax: A Close Comparison

The Ultramax is another type of geared dry bulk carrier that is slightly larger than the Supramax. Ultramax vessels typically have a deadweight tonnage (DWT) of 60,000 to 65,000, allowing them to carry more cargo. However, the difference in size and capacity between the two is not drastic.

Some key differences between Supramax and Ultramax vessels include:

- Size: Ultramax carriers are larger, with a length of around 200-220 meters, a beam of 35-37 meters, and a draft of 12-14 meters.

- Carrying capacity: Ultramax vessels have a slightly larger cargo-carrying capacity compared to Supramax carriers.

- Navigational capabilities: While both vessel types are versatile and able to navigate a variety of waterways, Supramax carriers have an advantage in narrower or shallower waters due to their slightly smaller size.

Despite these differences, both Supramax and Ultramax carriers share similar advantages, including their geared design and ability to operate in ports with limited infrastructure.

Scrubbers: Enhancing Supramax Vessel Efficiency

During dry docking, Supramax vessels may undergo upgrades to improve their efficiency and reduce their environmental impact. One such upgrade is the installation of a scrubber, a device that removes sulfur dioxide and other pollutants from the ship’s exhaust gases.

Scrubbers not only help Supramax vessels meet strict emission regulations, but they also improve fuel efficiency and reduce operating costs. As environmental regulations continue to tighten, scrubbers are becoming an increasingly important addition to Supramax carriers.

Pacific Basin: A Leader in Supramax Shipping

Pacific Basin is a prominent shipping company with a large and versatile fleet of Supramax vessels. With a focus on sustainability and operational efficiency, Pacific Basin is committed to providing reliable, cost-effective, and environmentally responsible shipping solutions.

Their Supramax fleet is designed to accommodate a wide range of cargo types, including dry bulk commodities like coal, iron ore, and grain. By leveraging their fleet of Supramax carriers, Pacific Basin can offer flexible, efficient shipping services that cater to the needs of their clients.

Conclusion

Supramax bulk carriers are an essential part of the global shipping industry, known for their versatility, efficiency, and impressive carrying capacity. With shipping companies like Pacific Basin leading the way, these vessels continue to play a crucial role in transporting goods across the world.

As environmental regulations become more stringent, upgrades like the installation of scrubbers will help to ensure that Supramax vessels remain competitive and environmentally responsible.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025