Boil-off Gas (BOG) is an essential yet often overlooked component in the maritime industry.

As liquefied natural gas (LNG) gains traction in global shipping, understanding and managing BOG becomes paramount. The evaporation of LNG during transport and storage can lead to significant safety and efficiency concerns.

Moreover, with the maritime sector’s increasing focus on sustainability, BOG’s potential as an alternative fuel source is becoming evident.

Addressing the challenges and harnessing the opportunities presented by BOG is crucial for the next phase of maritime advancements.

Key Takeaways:

- The Science Behind BOG: Beyond simple evaporation, BOG involves complex thermodynamic processes. Differences between LNG and LPG play a pivotal role in understanding BOG generation.

- Impacts and Management of BOG: Ensuring safe and efficient maritime operations requires effective BOG management strategies, especially with varied LNG carrier types.

- Future Directions and Innovations: The maritime industry is exploring ways to turn BOG from a challenge into an opportunity, with dual-fuel engines and Bio-LNG offering promising avenues.

Introduction to Boil-off Gas (BOG)

In the annals of maritime history, few developments have been as transformative as the rise of Liquefied Natural Gas (LNG). But with the ascent of LNG as a preferred maritime fuel, came the nuanced challenge of managing Boil-off Gas (BOG). BOG, simply put, is the natural gas that evaporates during the storage and transportation of LNG.

Historically, as maritime industries began to embrace LNG, they encountered the problem of this evaporation. The cryogenic temperature at which LNG is stored ensures that the gas remains in a liquid state.

However, despite the best containment measures, a small percentage of the LNG begins to revert to its gaseous state, leading to BOG. This phenomenon isn’t just a recent challenge; it has been a point of contention ever since LNG carriers first sailed the seas.

“The evaporation of LNG is more than just a process; it represents both a challenge and an opportunity in the maritime sector.”

The significance of managing BOG becomes paramount when considering the intricate balance of safety, efficiency, and environmental responsibility in the maritime sector.

While on one hand, BOG represents potential waste and a safety hazard, on the other, it’s seen as a potential alternative fuel source, which if harnessed properly, can drive the maritime industry towards a more sustainable future.

By understanding the history of LNG evaporation and the role of BOG, maritime professionals can equip themselves with the knowledge to tackle the challenges and leverage the opportunities it presents.

In the subsequent sections, we’ll dive deeper into the science behind BOG, its management, and its future in the maritime world.

The Science Behind BOG

When diving into the world of maritime fuels, the science behind Boil-off Gas (BOG) emerges as a fascinating study in thermodynamics. At its core, BOG is the result of the intricate dance between temperature, pressure, and the physical properties of Liquefied Natural Gas (LNG).

LNG, when stored in cryogenic storage tanks, remains at temperatures nearing -162°C. This ultra-cold environment ensures that the gas remains liquefied, thus enabling efficient storage and transportation.

However, as the LNG absorbs heat, either from the environment or operational processes, it begins to vaporize. This vaporization, often referred to as “LNG boil-off” or “gas generation,” is the primary cause behind BOG.

“Just as water boils at 100°C, turning from liquid to vapor, LNG has its own boiling point at cryogenic temperatures. The challenge? Keeping it below that point.”

This process isn’t just a straightforward evaporation. It’s affected by the temperature differential between the LNG and its surroundings, the insulation of the storage tanks, and the inherent properties of the LNG itself. But the science doesn’t stop at mere evaporation.

The challenge also lies in how to manage this BOG, either by re-liquefying it or using it as fuel.

Difference between LNG and LPG in the Context of BOG

When discussing BOG, it’s vital to distinguish between LNG and its close relative, Liquefied Petroleum Gas (LPG). While both are hydrocarbon gases liquefied for storage and transportation, their behavior under pressure and temperature variances is distinct.

LNG is primarily methane, and its cryogenic storage requirements stem from its very low boiling point. LPG, on the other hand, is a mix of propane and butane. Its storage is less stringent, often held under moderate pressures to keep it in liquid form.

This difference in volatility means that LPG boil-off is less frequent than LNG boil-off, even though both are stored in insulated tanks to minimize temperature fluctuations.

However, this isn’t a mere academic distinction. For maritime professionals, understanding the storage differences between LNG and LPG, and the associated challenges, can make a substantial impact on operational efficiency and safety.

In the next sections, we will delve into the intricate world of BOG management and its significance in the maritime industry’s journey towards sustainability.

Impacts and Management of BOG

The maritime world’s embrace of Liquefied Natural Gas (LNG) as a pivotal fuel source comes with the nuanced challenge of Boil-off Gas (BOG) management. BOG, while often perceived as a mere byproduct of LNG storage, carries profound implications on safety, operational efficiency, and environmental sustainability.

LNG carriers, the behemoth vessels that transport this precious cargo, face the constant challenge of maintaining their LNG below its boiling point. Even minor lapses in this balance can result in the generation of significant volumes of BOG.

Left unmanaged, this BOG can lead to over-pressurization of storage tanks, necessitating venting—a process where excess gas is released into the atmosphere. While venting might provide a quick fix, it comes at the cost of environmental impact and the loss of valuable fuel.

“Imagine pouring a portion of your fuel into the sea, every journey. That’s the operational and economic impact of unmanaged BOG.”

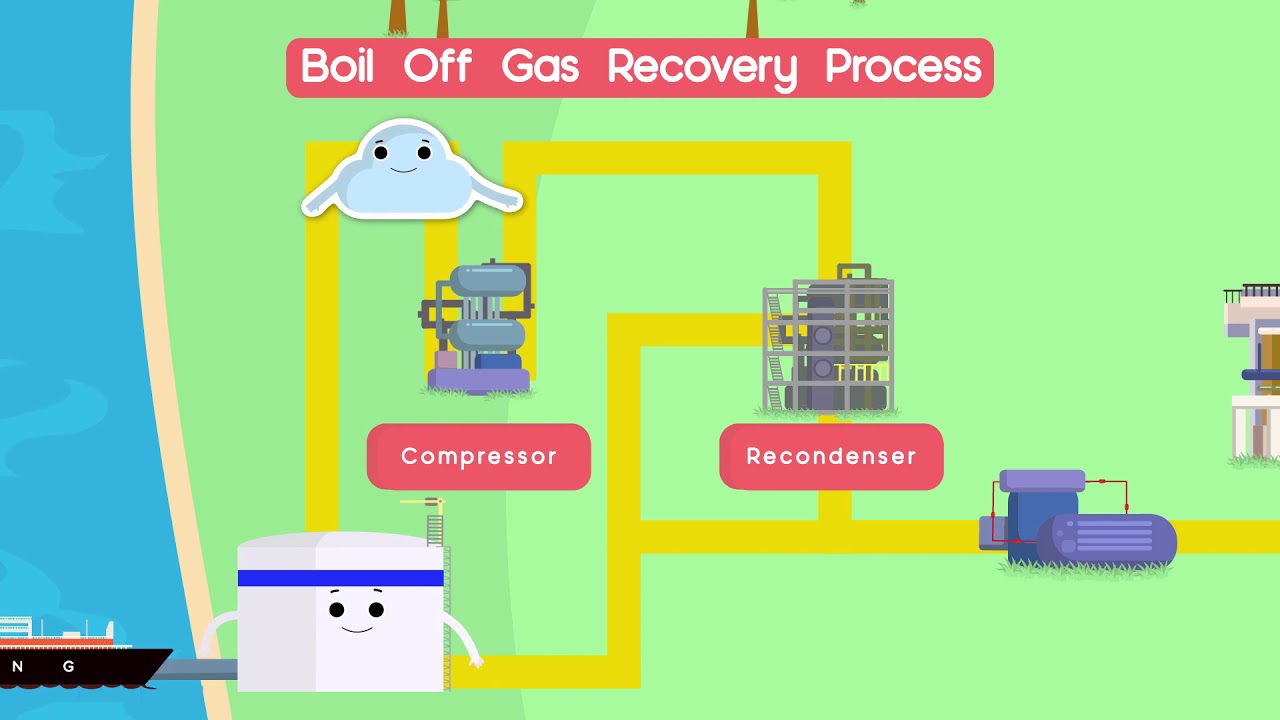

But modern maritime practices and technologies are evolving to address these challenges. From advanced containment systems that minimize heat ingress to re-liquefaction plants onboard that convert BOG back into liquid form, the industry is innovating at breakneck speed. Experts often emphasize the importance of holistic BOG management, not just as a safety protocol but as a pillar of operational efficiency.

Types and Sizes of LNG Carriers and Their Relevance to BOG

The maritime industry showcases a diverse range of LNG carriers, each with its unique design and capacity. From the colossal Q-Max vessels with capacities exceeding 260,000 cubic meters to the smaller coastal vessels, the spectrum is vast.

But how does the type and size of a carrier influence BOG generation?

Two predominant containment systems dominate the LNG carrier landscape: the Moss type and the membrane type. Moss type, characterized by its spherical tanks, offers the advantage of reduced BOG generation due to its minimized surface area.

The membrane type, on the other hand, utilizes thin walls and multiple barriers, optimizing space but requiring advanced insulation to manage BOG.

The size of the carrier further complicates the BOG equation. Larger vessels, while offering economies of scale, come with increased LNG volumes and, by extension, increased potential for BOG generation. Their sheer size demands advanced BOG management systems, often integrating both venting and re-liquefaction.

“Choosing the right LNG carrier is akin to choosing the right tool for a job. Each has its strengths, but understanding their BOG implications is crucial.”

Industry best practices emphasize the importance of tailored BOG management strategies, aligning with the specific type and size of the LNG carrier. As we venture deeper into the maritime world’s green transition, the effective management of BOG stands as a testament to the industry’s commitment to innovation and sustainability.

Using BOG as a Fuel

In the evolving maritime landscape, sustainability and operational efficiency are more than mere buzzwords; they are imperatives. One of the most promising avenues in this transformation is the utilization of Boil-off Gas (BOG) as a fuel. Historically viewed as a challenge, BOG, when harnessed correctly, stands as a testament to the maritime industry’s ingenuity.

As LNG carriers traverse the oceans, the BOG they generate isn’t just a byproduct to be managed; it’s a potential fuel source. By channeling this gas into the vessel’s propulsion systems, carriers can significantly enhance their operational efficiency while reducing their carbon footprint.

“From waste to wonder, BOG represents the maritime industry’s commitment to a greener, more sustainable future.”

This paradigm shift, from seeing BOG as a challenge to viewing it as an opportunity, is underpinned by advancements in engine technology, most notably, the rise of dual-fuel engines.

The Role of Dual-Fuel Engines in Utilizing BOG

At the heart of this BOG revolution lies the dual-fuel engine. As the name suggests, these engines can operate on two types of fuel: traditionally used marine diesel oil and now, the vaporized form of LNG, which includes BOG.

The technical advantages of these engines are manifold. They offer flexibility in fuel choice, allowing ships to switch between fuels based on availability and cost. Furthermore, by utilizing BOG, these engines significantly reduce the vessel’s reliance on external fuel sources, translating into notable cost savings.

But the benefits aren’t just operational. From an environmental standpoint, dual-fuel engines are a game-changer. Burning BOG results in reduced carbon emissions compared to traditional fuels, positioning these engines at the forefront of the green shipping movement.

“Dual-fuel engines aren’t just about fuel flexibility; they’re a nod to a world where shipping leaves a lighter footprint.”

Incorporating dual-fuel engines into the maritime world, especially in LNG carriers, is more than a strategic decision; it’s an environmental commitment. As we navigate the waves of change, the efficient utilization of BOG stands as a beacon, guiding the industry towards a more sustainable horizon.

Future of BOG Management and Global Standards

As we chart the course of the maritime industry, one thing becomes abundantly clear: the future is green. Boil-off Gas (BOG) management, once a niche concern, now stands at the intersection of technological innovation and global sustainability efforts.

The global maritime community, spearheaded by bodies like the International Maritime Organization (IMO), is actively shaping standards that prioritize both environmental responsibility and operational efficiency. These standards are not merely guidelines but represent a collective commitment to reduce the industry’s carbon footprint.

“The maritime world is not just adapting to change; it’s leading the charge towards a sustainable future.”

Technological advancements are poised to redefine the landscape of BOG management. From AI-driven containment systems that preemptively manage temperature differentials to advanced re-liquefaction processes that ensure minimal waste, the horizon is promising.

However, the most significant leaps are likely to be in the realm of fuels. The industry’s transition to sustainable fuels is not just an operational decision but an environmental imperative.

Bio-LNG and its Relationship with BOG

Emerging at the forefront of sustainable maritime fuels is Bio-LNG. Derived from organic waste, Bio-LNG represents a seismic shift from conventional LNG, offering a carbon-neutral alternative. Its rise is not just a testament to technological prowess but a nod to the maritime industry’s commitment to sustainability.

But where does BOG fit into the Bio-LNG narrative? Interestingly, the properties of Bio-LNG ensure that its evaporation rate, and consequently, its BOG generation, is on par with conventional LNG. However, the green credentials of Bio-LNG mean that even if this gas is vented or used as fuel, the environmental impact is negligible.

“Bio-LNG is not just another fuel; it’s a statement of intent, a commitment to a world where shipping harmonizes with nature.”

As the maritime industry sails towards this sustainable horizon, the synergy between innovations in BOG management and the rise of sustainable fuels like Bio-LNG will play a pivotal role. Together, they symbolize the industry’s unwavering commitment to a future where the waves are greener and the journey, more responsible.

Conclusion

The intricate dance of Boil-off Gas (BOG) within the maritime realm encapsulates the industry’s broader journey: a move from challenges to opportunities, from conventional methods to innovative solutions. The management of BOG, while technical in its nuances, is emblematic of the maritime sector’s larger commitment to sustainability and operational excellence.

From understanding the science behind BOG generation in LNG carriers to harnessing it as a viable fuel source, the industry has come a long way. And with the advent of sustainable fuels like Bio-LNG, the future looks even more promising.

“In the vast expanse of the maritime world, the management and utilization of BOG is a beacon, illuminating the path towards green initiatives and maritime sustainability.”

As we chart the course of the future, the developments around BOG will undoubtedly play a pivotal role, shaping not just operational strategies but the very ethos of the maritime industry.

Additional Resources

Leading LNG Carrier Operators

For those keen on understanding the major players driving the LNG carrier industry, this resource provides an in-depth look. Dive into the world of maritime giants, their operational strategies, and how they are shaping the industry’s future.

Understanding Ship Order Books

The ship order book, while seemingly a niche topic, offers profound insights into the maritime industry’s pulse. This resource demystifies ship procurement, offering a window into industry trends, demands, and future trajectories.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025