Cargo ships consume a hefty amount of fuel every day especially when it is under voyage. Hence, it is necessary to plan in advance when and where to take fuel in order to make sure the vessel can still arrive at its port of call.

Bunkering is the process of supplying fuel or marine gas oil to supply energy to the propulsion and generators on ships. It is achieved either onshore where bunkers are supplied by tanker trucks or pipelines through bunker hoses or offshore where bunker barge goes to the ship to deliver fuel.

It is very important to check the quantity of the bunker for it is delivered in volume but paid in weight. Aside from the quantity, the quality of the bunker is the so needed to be checked using sample bottles attached to the bunker manifold during bunkering because a bad bunker can cause harm to the propulsion engine and the generators.

What Are The Duties While Bunkering On Ships?

Bunkering operation requires full attention to avoid any oil spills on the water and may cause harm to the environment. This is why designated persons are assigned their duties to perform during the operation such as:

Chief Engineer: The person in charge of the Bunkering On Ships

All persons will report to him prior to bunkering. He will address all safety items, and review all local and federal regulations. Moreover, when assigned personnel associated with the transfer fully understand their duties, the Chief Engineer himself will notify the Master of the ship to request permission to commence bunkering.

The Chief Engineer will note in the Engineer logbook any special instructions regarding the transfer, which will be followed by his subordinates. Aside from this, he will be in charge of inspecting and signing the Declaration of Inspection Form.

The following personnel will assist the Chief Engineer in the preparation and execution of oil transfers:

Second engineer

The second engineer is the second in command for the engine department and thus he will make sure that all tanks and valves must be double-checked. He will also supervise the engine crew and keep them updated if there are any changes during the bunkering operation.

The second engineer will also assist the chief engineer in calculating the amount of fuel that is being transferred from time to time by sounding the tanks and tank calibration book.

Duty Deck Officer

The duty deck officer will check all the mooring of the vessel and barge. In addition, he ensures that all scuppers are closed, and all safety signs are posted (i.e., No smoking, no open flame, restriction of personnel from the vessel, etc.).

Also, he checks that all doors, portholes, and vents are closed to avoid any entry of harmful gases to the accommodation from bunkering. The duty deck officer also provides two fire hoses, dry powder portable extinguishers, buckets of sand, and shovels for emergency purposes like oil spills or fire. Moreover, he continues to check the mooring condition of the vessel and barge and keeps all personnel advised of any weather changes.

3rd Engineer

The third engineer will assist the Chief Engineer during bunkering. He is to supervise appointed motormen during bunkering operations. He is also in charge of checking the operational condition of the fuel system, vents pipes, sounding pipes, opening, and closing of fuel valves, drip pan containment, and flange connections.

He must ensure that all fuel oil containment must be empty before transfer and check fuel sounding in all tanks as well as a record in the sounding logbook before transfer.

Motormen/Oilers

The assigned oiler will assist the 3rd Engineer on duty. He will take soundings every 10 minutes and check the general conditions around the deck for safety. Meanwhile, the other oiler assigned will continuously control and inspect the manifold area with regular reports on pressure.

What To Check Before, During, And After Bunkering On Ships?

First of all, before any bunkering operation commences, make sure to hand over the bunkering plan to each individual that is assigned to the operation to know how much is going to be loaded into the bunker tanks, and what is the final sounding on the pipes.

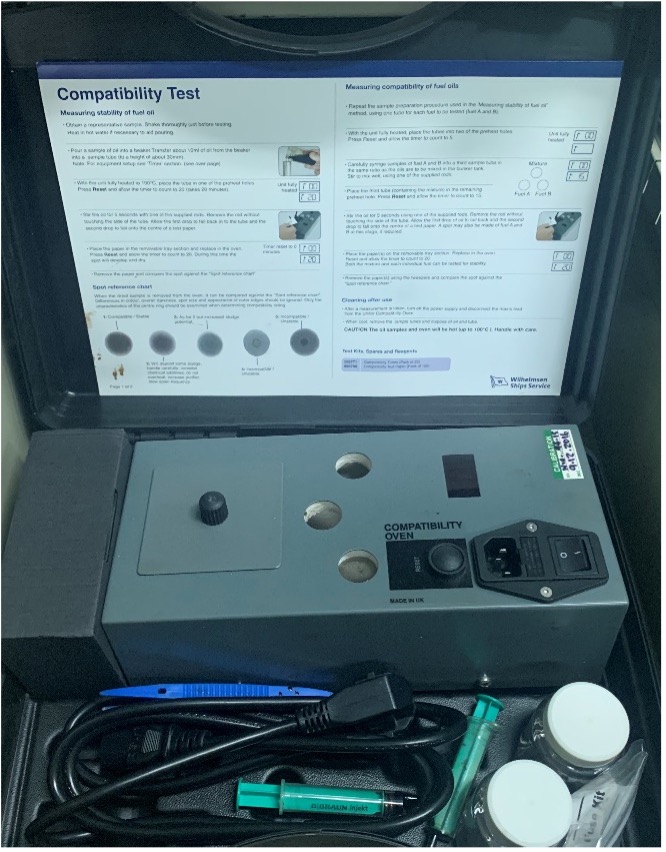

In the case of fuel oil, the remaining fuel must be transferred to one tank to avoid mixing with the new fuel to be bunkered. But if ever there is still fuel remaining, and that tank needs to be filled, a compatibility test is yet to be done before the bunkering operation continues. If it is compatible, then the new fuel can be added with the old fuel on the tank, but if not, the bunkering will be stopped and both parties must agree on how much fuel is loaded onto the ship.

Checklist for Bunkering On Ships

Now, once the team is already briefed on the situation on hand, the designated person is now to tick all that needs to be checked on the bunkering checklist. Some of these are:

- Are the bunkering hoses in good condition?

- Are bunkering hoses correctly connected and dip trays in position?

- Are the valves of the receiving tank open?

- Is the capacity of the receiving tank checked?

- Are the designated personnel aware of the maximum percent that can be loaded on the tanks?

- Are the scuppers plugged in?

- Are the communication system and channel agreed upon by both parties?

- Is the operation procedure agreed upon by both parties?

- Is the emergency equipment such as SOPEP materials, fire hoses, and absorbing cloth nearby ready?

- Is the transfer hose properly rigged and the flanges securely bolted?

Density and Quantity of Bunker Fuel

As fuel is delivered in volume but paid for by weight, it is vital that the exact density must be known, in order to find out how many tons of fuel the ship actually receives. This can be achieved by checking the temperature of the bunker on the barge.

In addition, the volume of fuel can be made to be larger than it seemingly is if the fuel contains a lot of air in it. This is also known as the cappuccino effect. So, if the quantitative determination of fuel is not managed properly, it may lead to huge financial losses for the company.

To make sure that the quantity of fuel bunkered is accurate, always sound the tanks that is going to be filled, as well as set a designated person to check the sounding of the barge’s fuel tank and the table of calibration that they are using.

Bunker Fuel Sampling

During bunkering on ships, the assigned crew must report the pressure on the manifold in a timely manner, as well as the sounding of the tanks.

A fuel sample bottle must be attached to the manifold with the use of a “continuous drip feed sampler” to extract fuel samples to be able to send them ashore for analysis. In order to make sure to collect samples throughout the bunkering operation, the needle valve needs to be adjusted and monitored.

Furthermore, the fuel sample bottle must be able to contain enough samples to fill all the containers that are needed afterward. The samples that the ship should take are the MARPOL sample, a retain sample for the ship, a retain sample for the bunker barge, a sample for the shore analysis and if ever a bunker surveyor is present, he will also take a sample for himself.

In addition, the bunker barge must also give the ship a fuel sample that is taken from their manifold in a proper manner.

Bunker Delivery Note (BDN)

According to MARPOL regulations, details of fuel oil for combustion purposes delivered to the ship and will be used onboard shall be recorded using the bunker delivery note. This is why a BDN is very important and shall be presented for every delivery made. Furthermore, the BDN must be kept onboard and must be presented when needed at all times. The representative of the delivery party should sign the BDN to confirm the following:

- The fuel supplied has sulfur content as specified.

- That it will not be harmful to personnel nor contribute to air pollution.

- That it is free from inorganic additives, added substances, or chemical waste.

- That the fuel will have no adverse effect on the pieces of machinery when used to

On the other hand, the BDN might be prepared before the delivery. But this might not reflect the fact of the delivery. So, it is advised not to sign any documents, labels, or tags before the bunkering is finished.

Disputes in Bunkering On Ships

Disputes can happen if there is a lack quantity of fuel or the quality of the fuel is an issue. So as far as possible, disputes should be taken care of immediately and peacefully. This is because disputes can be time-consuming and can have an expensive process.

In addition, the best chances of succeeding in a dispute are, if all the information and all the facts needed are gathered together to be able to find where the problem is. Lastly in order to avoid disputes in the first place, make sure to have good procedures and keep records onboard.

What causes oil spills on bunkering

Oil spills during bunkering can be caused by hose damage or even loose bolt-on flanges. Not to mention, the negligence of the attendant on the manifold or miscommunication.

Sometimes, it is because of unopened valves to the entry of the tank that is to be filled or unbriefed and incompetent crew that are given responsibilities for the bunkering operation.

All these undesirable events will lead to financial problems for the company and even worse, harm the environment that we should be keeping safe in the first place. To do so, in order to prevent this disastrous event, have a pre-bunkering meeting in order to refresh and guide the crew on what to do and what to pay attention to. Remind them the first thing to do during an actual oil leakage is to prevent it from spilling overboard.

To summarize it all, bunkering is the process of delivering fuel to aid the combustion of the propulsion on ships as well as the generators. Unfortunately, bunkering operations can lead to unwanted events such as oil spills if the procedures are not followed well.

To have a safe bunkering operation, make sure to check everything before the bunkering commences. Double-check all the valves that need to be opened and closed, check the hoses and the spill boxes, and the tanks to be filled. In addition, make sure to brief all personnel that is involved in the operation.

Lastly, make sure to sound your tanks as well as the tanks of the bunker barge in order to have some information and facts that can be helpful if there is a lacking of quantity and quality of fuel that may lead to disputes.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025