As we progress towards innovation in the late 1960s, the size of oil tankers rapidly increased due to high demands, thus increasing also the incidents of explosions on tanks. The explosions were due to the ignition of flammable vapors in the tank’s atmosphere.

The ignition source in many cases was the static electricity charge that build up in the tank’s atmosphere during cargo and ballast operation and especially tank cleaning operations. This led to global changes and conventions to introduce an inert gas system to counter rising incidents and protect more life from explosions.

The inert gas system’s function is to minimize and if not remove the risk of explosions throughout the tanks by suppressing the combustion gases to a minimum. In addition, inert gas introduced to the tanks contains insufficient oxygen which dilutes the combustion of flammable hydrocarbon gases.

The inert gas system or IG system distributes inert gas to the tanks that are over-rich with hydrocarbon gases to increase the lower explosion limit (the lower concentration where the vapors can be ignited), as well as decrease the higher explosion limit (the higher concentration where the vapor will explode).

Oil tankers carry different kinds and grades of oil, having the property to produce flammable gases when loaded and unloaded at different ports. Even if it has no cargo, still it can contain harmful gases which can cause an explosion when diluted with air.

That’s why an inert gas system was introduced to counter the risks of explosion by adding inert gas to make the oxygen content less than 10% by volume. With this, a mixture of hydrocarbon gases will not be flammable.

Moreover, if a tank is inserted with <5% oxygen by volume, one side of the fire triangle has been already removed (fuel, oxygen, and fuel) thus making the atmosphere inside the tank combustion-proof.

As per regulations of The International Convention for the Safety of Life at Sea (SOLAS 1974), the inert gas systems on ships must be able to produce an inert gas with an oxygen content no higher than 5% by volume. By continuously maintaining a pressure that is higher inside the tanks, than the surrounding atmosphere, and ensuring that the air inside the tank does not contain more than 8% oxygen by volume, it makes the atmosphere inside the tank non-flammable. This is an essential safety measure to protect the ship and its cargo.

Why Inert Gas System Is Important?

The process of combustion is always pictured as a fire tetrahedron. Each side of the fire tetrahedron is labeled as the components to build a fire, they are labeled “oxygen”, “heat”, “fuel” and “chain reaction” accordingly. When one of the sides is missing, it can’t produce fire and that’s the purpose of an inert gas system.

An inert gas system is used to lower the oxygen content in the tanks in order to avoid combustion and explosion. Taking out oxygen means taking out one side of the fire tetrahedron in order not to build a fire. By this stage, it increases the crew and the vessel’s safety as well as avoids any environmental incidents.

As we continue to study the importance of inert gas systems, here are some terminologies that are commonly used onboard during loading, discharging, or tank cleaning operations.

- Inert gas – a gas or mixture containing insufficient oxygen to support the combustion of hydrocarbons.

- Inert condition – a condition in which the oxygen content throughout the atmosphere of the tank has been reduced to 8% or less by volume by the addition of inert gas.

- Inerting – the introduction of inert gas into a tank with the object of attaining an inert condition where the oxygen content throughout the atmosphere of a tank is 8% or less by volume.

- Gas freeing – the introduction of fresh air into a tank with the object of removing toxic, flammable, and inert gases and increasing the oxygen content to 21% by volume.

- Purging – the introduction of inert gas into a tank already in the inert condition with the object of:

- further reducing the existing oxygen content

- or reducing the existing hydrocarbon gas content to a level below which combustion cannot be supported if the air is subsequently introduced into the tank

- Topping up – the introduction of inert gas into a tank that is already in inert condition with the object of raising the tank pressure to prevent any ingress of air.

Advantages And Disadvantages Of Inert Gas System (IGS)

As most of the systems have pros and cons, inert gas systems also have some advantages and disadvantages of their own.

Here are some of the advantages of the IGS

- The corrosion rate is significantly lower in exposed tank structures if the oxygen content is kept <8% by volume

- As it suppresses the oxygen content, it makes the atmosphere inside the tank explosion-free

- Time is reduced when cleaning the tanks as it allows high-pressure tank washing with the use of large tank-washing machines.

- Since the tanks are pressurized by IG, it makes the stripping efficient and reduces discharging time.

- It complies with international conventions for SOLAS to have a safer operation for the crew and the vessel as well as for the protection of the environment.

Unfortunately, as we have advantages, we also have some disadvantages to tackle for IGS

- Since a system is needed to install, it burdens the owners of the ships with the additional costs for the installation of the IGS.

- As the system parts gradually deteriorate, additional maintenance and spares for the system are needed.

- Oxygen content should always be monitored at all times otherwise you’ll be operating your system with the atmospheric valve open since gases with high oxygen content will be released into the atmosphere.

- If not maintained, failure of instrumentation could affect the production of IG and may endanger the crew and the vessel.

How Is Inert Gas Produced

There are many ways to produce and introduce inert gas in the tanks in order to lower the oxygen content. These are the following:

Independent inert gas generator system – this kind of system is capable of producing gas with an oxygen content of less than 3% per volume. This system is fitted when there is no boiler available or when the oxygen content that is needed is below 3%.

Along with this, it is fitted with a high-efficiency burner unit with a water-jacketed furnace, that is usually operated with distillate fuel to produce cleaner and lower oxygen content.

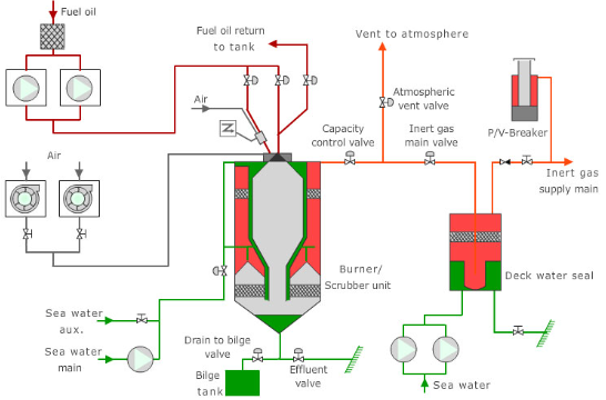

Flue gas systems – use normal boiler exhaust gas as means to produce inert gas. Moreover, boilers that are efficiently operated can produce an oxygen content of less than 5%. When it comes to its exhaust gas, it needs a scrubber unit to clean and cool them before it is used in any cargo tanks.

In addition, most crude oil carriers that is fitted with steam turbine cargo pumps use flue gas from the boilers since it is readily available when using boilers to produce steam.

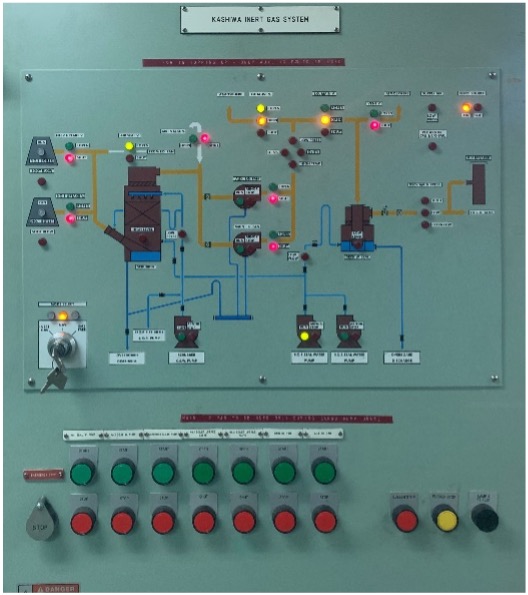

Example of inert gas system panel for flue gas system:

Combination inert gas system – these systems are fitted on ships where flue gas supply is not always enough or available that’s why oil-fired burner is used to supply the lacking need for inert gas

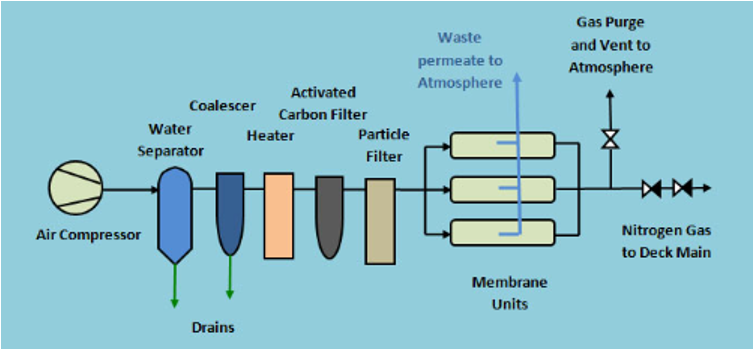

Nitrogen generator system – as the name itself, nitrogen is a natural inert gas that can be used to lower oxygen content and destabilize combustion in tanks. They are used commonly by gas and chemical tankers where high-quality inert gas is required for each tank.

The nitrogen generator system is fitted with an air compressor, water separator, filters, and some hollow membrane units. Air is compressed, dried, and heated before it is passed through the hollow fiber membrane. The oxygen and carbon dioxide pass through the walls of the hollow membrane, leaving only the nitrogen that is then pumped to the tanks to keep them inerted.

What Is An Inert Gas Generator System?

Ships that don’t have an oil-fired boiler will have an alternative source of inert gas by installing an independent oil-fired inert gas generator or a nitrogen generator system. Independent inert gas generators are efficient since they only need to be connected to the ship’s fuel, and water supply as cooling media.

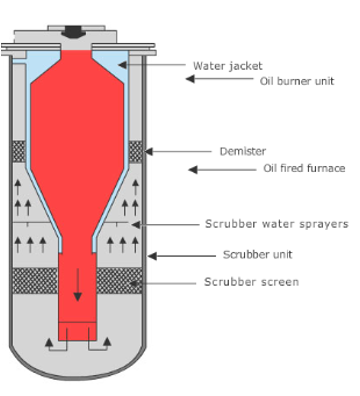

An oil-fired inert gas generator typically consists of a self-contained oil burner unit and a water-cooled combustion chamber. The water jacket surrounding the chamber is built to prevent overheating during firing. The gas that is produced is cooled and cleaned by an integral scrubber unit that has water sprays and demister.

Fans are also provided for the combustion of air and gas flow as well as cooling water and scrubber pumps. In addition to this, fuel pumps, controls and instrumentations are also installed as part of its self-sufficient inert gas generator.

In general, inert gas generators use distilled marine gas oil to produce cleaner and high-quality gas as well as lower oxygen content. Also, it has a dedicated scrubber pump only for cooling and cleaning the gas produced during firing.

Seawater used for cooling the gas will be drained or stored in a bilge tank depending on port regulations. Moreover, the fans that are installed must be of an electrically driven centrifugal type which has the capacity to ensure gas flow within the system. Once there is already production of inert gas, it is then delivered to the deck seal to be introduced to the tanks to keep them inerted.

PV Breaker In IG System

A PV breaker, also known as a pressure-vacuum breaker, is a critical component of an inert gas system onboard an oil tanker. Its purpose is to prevent the ingress of air into the cargo tanks and the release of vapor from the tanks into the atmosphere. It is typically located on the cargo tank vent line, and it consists of a spring-loaded valve that opens or closes based on the pressure differential between the inside of the cargo tank and the atmosphere.

The PV breaker is designed to open when the pressure inside the cargo tank exceeds a certain level, allowing excess vapor to escape and preventing the tank from becoming over-pressurized. Conversely, it will close when the pressure inside the cargo tank drops below a certain level, preventing air from entering the tank and maintaining the inert atmosphere.

For more detailed information about the construction and working principle of a PV breaker, you may refer to the article “What Is PV Valve And PV Breaker On Ships?”

To summarize, an inert gas system is installed onboard in order to produce inert gas to keep the oxygen content to a minimum so that it cannot support any combustion inside the tank.

The inert gas system’s purpose is to eliminate one side of the fire tetrahedron (which is by lowering the oxygen content) to prevent any risk of fire. This was amended to keep the life of the crew and the vessel away from any incidents that may occur during operations such as explosions.

Lastly, the production of inert gas doesn’t seem that much of a problem onboard since there are several ways to produce them such as flue gas from the boilers, nitrogen generator systems, and inert gas generator systems.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply