Shipping is an essential component of global trade, transporting goods from one corner of the world to another. Within the shipping industry, there are two main types of cargo: bulk and break bulk. In this article, we will explore the differences between these two types of cargo, along with their respective handling, storage, transportation, advantages, and disadvantages.

Definition of Bulk and Break Bulk Cargo

Bulk Cargo

Bulk cargo refers to large quantities of homogeneous, unpackaged goods that are transported in massive volumes. They are typically stored and transported in bulk carriers, specialized ships designed for the purpose of carrying large volumes of cargo.

Break Bulk Cargo

Break bulk cargo, on the other hand, consists of goods that are individually packaged or bundled and loaded onto the ship. These goods are not uniform in size or shape and often require special handling, storage, and transportation methods.

Types of Bulk

Dry Bulk

Dry bulk cargo comprises solid, granular, or particulate materials such as coal, grain, or minerals. These goods are typically transported in large carriers designed to hold and unload dry bulk cargo.

Dry bulk cargo comprises a variety of solid, granular, or particulate materials that are transported in large quantities. Some examples of dry bulk cargo include:

- Coal: Coal is a key component in the energy sector and is used for electricity generation, steel production, and cement manufacturing.

- Grain: Various types of grain, such as wheat, corn, and soybeans, are transported worldwide to meet the food demands of a growing global population.

- Iron ore: Iron ore is a critical raw material in the steel industry and is shipped in large quantities to steel mills around the world.

- Fertilizers: Fertilizers, such as urea, potash, and phosphate, are vital for agricultural productivity and are transported as dry bulk cargo.

- Sand and aggregates: Sand, gravel, and crushed stone are essential for construction projects and are often shipped as dry bulk cargo.

Liquid Bulk

Liquid bulk cargo includes fluids like oil, petroleum products, and chemicals. These substances are transported in specialized tanker ships designed to hold and transport large volumes of liquid cargo safely.

Liquid Bulk

Liquid bulk cargo includes various fluid substances that are transported in large volumes. Some examples of liquid bulk cargo are:

- Crude oil: Crude oil is the primary raw material for the production of gasoline, diesel, and other petroleum products, and is shipped in large quantities in tanker ships.

- Refined petroleum products: Gasoline, diesel, jet fuel, and other refined petroleum products are transported as liquid bulk cargo to meet global energy demands.

- Chemicals: Industrial chemicals, such as solvents, acids, and bases, are shipped in large volumes for use in various industries, including manufacturing, pharmaceuticals, and agriculture.

- Vegetable oils: Liquid bulk cargo also includes edible oils, such as palm oil, soybean oil, and sunflower oil, which are essential ingredients in food production.

- Liquid natural gas (LNG): As the demand for cleaner energy sources grows, LNG is increasingly being transported as liquid bulk cargo to supply natural gas to various markets.

Types of Break Bulk

General Cargo

General cargo includes a wide variety of goods, such as consumer products, machinery, and equipment. They are usually transported in containers, crates, or pallets and can be loaded onto general cargo ships, container ships, or roll-on/roll-off vessels.

General cargo includes a wide array of goods that are shipped in smaller, individual packages or units. Some examples of general cargo include:

- Consumer products: Items such as clothing, electronics, and toys are often shipped as general cargo to meet consumer demands.

- Food and beverages: Packaged food products and beverages are transported as break bulk cargo to supply retail stores, restaurants, and other outlets.

- Machinery and equipment: Industrial machinery, agricultural equipment, and other specialized tools are shipped as break bulk cargo to support various industries.

- Spare parts: Automotive, aerospace, and other spare parts are often shipped as general cargo to maintain and repair equipment and vehicles.

- Building materials: Lumber, steel beams, and other building materials are transported as break bulk cargo for use in construction projects.

Project Cargo

Project cargo refers to oversized or heavy items, such as wind turbine components, power plant equipment, or large machinery, which require specialized handling and transportation. These cargoes are often carried on flat racks, specialized trailers, or heavy-lift ships.

Project cargo refers to oversized, heavy, or otherwise challenging items that require specialized handling and transportation. Some examples of project cargo include:

- Wind turbine components: The blades, towers, and other components of wind turbines are large and heavy, requiring specialized shipping methods and equipment.

- Power plant equipment: Boilers, turbines, and transformers for power plants are often shipped as project cargo due to their size, weight, and complexity.

- Modular housing units: Prefabricated building modules for housing, office spaces, or other structures can be transported as break bulk cargo.

- Industrial machinery: Large-scale manufacturing or processing equipment, such as printing presses or chemical reactors, often require specialized handling and transportation as project cargo.

- Infrastructure components: Bridge sections, rail tracks, and other infrastructure components are often shipped as project cargo due to their size and weight.

Handling of Bulk and Break Bulk Cargo

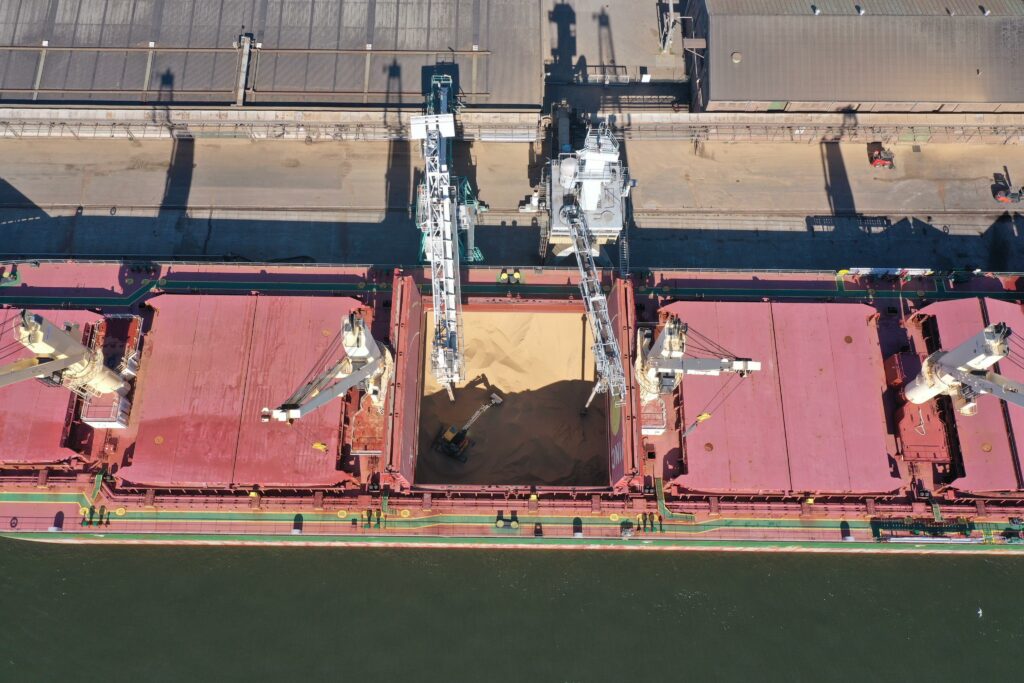

Bulk Handling Equipment

Handling bulk cargo typically involves specialized equipment designed to manage large volumes of cargo efficiently. Some common types of bulk handling equipment include:

- Conveyor belts: Conveyor belts are used to transport bulk materials from one location to another within a storage facility or between a ship and a storage facility. They are particularly useful for handling dry bulk cargo such as grains or minerals.

- Grabbers: Grabbers, or bulk cargo grabs, are mechanical devices attached to cranes that can efficiently pick up and release large quantities of dry bulk cargo. They come in various sizes and designs to accommodate different cargo types.

- Ship loaders/unloaders: Ship loaders and unloaders are large, specialized machines used to transfer bulk cargo between a ship and a storage facility. They can handle both dry and liquid bulk cargo, with some designs catering specifically to certain cargo types.

- Pumps and pipelines: For liquid bulk cargo, pumps and pipelines are used to transfer the cargo between ships, storage facilities, and transportation vehicles. Pumps can move large volumes of liquid cargo quickly and efficiently.

- Hoppers: Hoppers are funnel-shaped containers used for the temporary storage and handling of dry bulk cargo. They can be used to facilitate the transfer of cargo between different modes of transportation or storage facilities.

Break Bulk Handling

Handling break bulk cargo can be more complex due to the varying sizes, shapes, and packaging of the goods. Some common methods and equipment used for break bulk handling include:

- Forklifts: Forklifts are versatile vehicles that can lift, transport, and stack pallets or other cargo units. They are widely used for handling break bulk cargo in warehouses and storage facilities, as well as during loading and unloading processes.

- Cranes: Cranes, particularly mobile or shipboard cranes, are essential for lifting and moving heavy or oversized break bulk cargo. They can be equipped with various attachments, such as hooks, slings, or spreader beams, to accommodate different cargo types.

- Pallet jacks: Pallet jacks are manual or electric devices used to lift and move palletized cargo. They are particularly useful for handling smaller break bulk shipments within storage facilities or during loading and unloading processes.

- Specialized lifting gear: For certain types of break bulk cargo, such as project cargo or heavy machinery, specialized lifting gear may be required. This can include custom-made slings, shackles, or lifting frames designed specifically for the cargo in question.

- Container handling equipment: For break bulk cargo shipped in containers, specialized container handling equipment, such as reach stackers or container cranes, can be used to move and stack containers efficiently.

Break bulk cargo handling, also known as stevedoring, often requires a combination of manual labor and mechanical equipment to ensure that goods are loaded and unloaded safely and efficiently. This process can be more time-consuming and labor-intensive compared to bulk cargo handling, but it is essential for managing the diverse nature of break bulk shipments.

Storage of Bulk and Break Bulk Cargo

Bulk Storage Facilities

Bulk storage facilities are designed to accommodate large volumes of homogeneous goods. The type of facility used depends on the nature of the cargo being stored, whether it is dry or liquid. Here are some examples of bulk storage facilities:

- Silos: Silos are vertical storage structures used for storing dry bulk cargo, such as grains, cement, and fertilizers. They are designed to hold large quantities of materials, protect them from external elements, and facilitate easy loading and unloading.

- Tanks: Tanks are used for storing liquid bulk cargo, such as crude oil, chemicals, and liquid natural gas (LNG). They come in various sizes and materials, depending on the cargo being stored and environmental conditions.

- Stockpiles: Stockpiles are open storage areas used for bulk materials like coal, iron ore, or aggregates. They can be formed using earthmoving equipment or conveyor systems and are often located near transportation hubs, such as ports or railway stations.

- Domes: Domes are large, enclosed structures used for storing dry bulk cargo, such as minerals or agricultural commodities. They provide protection from the elements and can be equipped with ventilation systems to control humidity and temperature.

- Bins and hoppers: Bins and hoppers are smaller storage containers used for temporary storage or handling of dry bulk cargo. They can be used in conjunction with other storage facilities or transportation equipment, such as conveyor belts or ship loaders.

Break Bulk Storage

Break bulk storage facilities must accommodate a wide variety of cargo types, sizes, and shapes. They are designed to ensure easy access to individual shipments and efficient organization of goods. Some common types of break bulk storage facilities include:

- Warehouses: Warehouses are large, enclosed buildings used for storing a wide range of break bulk cargo. They can be organized with pallet racking systems, shelving units, or floor storage, depending on the type of cargo and storage requirements.

- Sheds: Sheds are smaller, open or partially enclosed structures used for storing break bulk cargo that may not require full protection from the elements. They can be used for goods such as lumber, steel, or other building materials.

- Open storage areas: Open storage areas, or laydown yards, are used for storing oversized or heavy break bulk cargo that cannot be accommodated indoors. These areas can be paved or unpaved and are often used for project cargo or machinery storage.

- Container yards: Container yards are specialized storage facilities designed to handle shipping containers. They are equipped with container handling equipment, such as reach stackers or container cranes, and can be used to store both loaded and empty containers.

- Cold storage facilities: Cold storage facilities are temperature-controlled warehouses used for storing perishable break bulk cargo, such as food products, beverages, or pharmaceuticals. They are designed to maintain specific temperature ranges and humidity levels to preserve the quality of the goods.

Proper organization and management of break bulk storage facilities are crucial to ensure efficient retrieval and distribution of goods. This can involve inventory management systems, proper labeling and documentation, and regular inspections to maintain the quality and safety of the stored cargo.

Transportation of Bulk and Break Bulk Cargo

Bulk Transportation

Bulk transportation involves moving large quantities of homogeneous cargo using specialized vehicles or vessels designed to accommodate the specific cargo type. Here are some examples of bulk transportation methods:

- Bulk carriers: Bulk carriers are ships specifically designed to transport dry bulk cargo, such as coal, grain, or iron ore. They come in various sizes, ranging from small coastal vessels to large Capesize ships, and are equipped with large cargo holds and specialized loading and unloading systems.

- Tanker ships: Tanker ships are designed to carry liquid bulk cargo, such as crude oil, chemicals, or liquefied natural gas (LNG). They have a series of large tanks or compartments to store the cargo and are equipped with pumps and pipelines for efficient loading and unloading.

- Railcars: Bulk cargo can also be transported using specialized railcars, such as hopper cars for dry bulk cargo or tank cars for liquid cargo. These railcars are designed to handle large volumes of goods and can be connected to form long trains for efficient transportation over long distances.

- Trucks: Bulk cargo can be moved by truck using specialized trailers, such as dump trailers for dry bulk cargo or tanker trailers for liquid cargo. Trucks offer flexibility in transportation routes and can be used for both short- and long-distance hauls.

Break Bulk Transportation

Break bulk transportation involves moving diverse cargo types, sizes, and shapes using a variety of vehicles or vessels. Here are some examples of break bulk transportation methods:

- General cargo ships: General cargo ships are versatile vessels that can accommodate a wide range of break bulk cargo, such as palletized goods, crates, or drums. They can be equipped with cranes or other loading equipment to facilitate cargo handling.

- Container ships: Container ships are designed to transport cargo packed into standardized shipping containers. They come in various sizes and can carry thousands of TEUs (twenty-foot equivalent units) at once. Containers offer a flexible and efficient means of transporting break bulk cargo, as they can be easily transferred between ships, trucks, and trains.

- Roll-on/roll-off (RoRo) vessels: RoRo vessels are specialized ships designed to carry vehicles and other wheeled cargo. They have built-in ramps that allow vehicles to be driven on and off the ship, making them particularly useful for transporting cars, trucks, buses, and heavy equipment.

- Trucks: Trucks are versatile vehicles that can be used for transporting break bulk cargo over short or long distances. They can be equipped with various types of trailers, such as flatbeds, box trailers, or refrigerated trailers, to accommodate different cargo types and requirements.

- Railcars: Break bulk cargo can also be transported by rail using a variety of railcars, such as boxcars, flatcars, or refrigerated cars. Rail transportation can be efficient and cost-effective for long-distance hauls, especially when transporting large volumes of cargo.

- Air freight: For high-value, time-sensitive, or perishable break bulk cargo, air freight can be the most suitable transportation method. Cargo aircraft can transport a wide range of goods quickly and efficiently over long distances, although this mode of transportation tends to be more expensive than other options.

The choice of transportation method for break bulk cargo depends on factors such as the type of cargo, distance, time constraints, and cost. Often, a combination of transportation methods, known as intermodal transportation, is used to optimize the efficiency and cost-effectiveness of the shipping process.

This can involve transferring cargo between ships, trucks, trains, and even planes, using standardized containers or other specialized equipment to facilitate smooth transitions between different modes of transportation. Proper planning, coordination, and communication between all parties involved in the transportation process are essential to ensure that break bulk cargo reaches its destination safely and on time.

Advantages of Bulk and Break Bulk Cargo

Bulk Cargo Advantages

Bulk cargo offers several advantages, including:

- Economies of scale: Shipping large quantities of cargo at once can reduce overall transportation costs.

- Efficient handling and storage: Specialized equipment and facilities designed for bulk cargo can streamline the handling and storage process.

- Reduced packaging: Bulk cargo typically requires less packaging, leading to lower costs and less waste.

Break Bulk Advantages

Break bulk cargo also has its advantages, such as:

- Flexibility: Break bulk shipping can accommodate a wide variety of cargo types, sizes, and shapes.

- Easier access: Smaller shipments can be more easily retrieved and distributed upon arrival at their destination.

- Less reliance on specialized equipment: Break bulk cargo can often be handled using more standard equipment, reducing the need for specialized machinery or vehicles.

Disadvantages of Bulk and Break Bulk Cargo

Bulk Cargo Disadvantages

Bulk cargo also comes with certain disadvantages, including:

- Limited cargo variety: Bulk shipping is best suited for homogeneous goods and may not be suitable for diverse cargo types.

- Investment in specialized equipment: Bulk cargo handling and transportation often require investment in specialized machinery or vehicles.

- Potential for contamination: Bulk cargo can be more susceptible to contamination due to the lack of individual packaging.

Break Bulk Disadvantages

Break bulk cargo has its own set of disadvantages, such as:

- Higher handling costs: The labor-intensive nature of break bulk cargo handling can lead to higher costs.

- Slower loading and unloading times: Break bulk cargo may require more time for loading and unloading due to the individualized nature of the goods.

- Greater potential for damage: Break bulk cargo is more susceptible to damage during handling and transportation due to its varied nature and packaging.

Conclusion

Understanding the differences between bulk and break bulk cargo is crucial for businesses and shipping professionals. Bulk cargo offers economies of scale, efficient handling, and storage, while break bulk cargo provides flexibility and easier access to goods. Each type of cargo has its own set of advantages and disadvantages, and choosing the right method depends on the specific needs of the cargo and the parties involved in the shipping process.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025