The maritime industry is undergoing a transformative shift, and at the heart of this change lies the LNG bunkering vessels list.

As environmental concerns take center stage globally, the maritime sector is not just observing but actively participating in the green revolution.

LNG (Liquefied Natural Gas) bunkering vessels are not merely symbols of this transition; they’re the tangible solutions for those in the industry seeking cleaner fuel alternatives.

Key Takeaways:

- Evolution of LNG Bunkering: Discover the journey of LNG as a marine fuel, tracing its growth and the pivotal role of bunkering vessels in this transformation.

- Safety and Regulations: Delve into the stringent safety protocols and international regulations that govern LNG bunkering, ensuring both environmental protection and crew safety.

- Future Trends: Gain insights into the technological advancements, challenges, and opportunities that lie ahead for LNG bunkering vessels, shaping the future of sustainable shipping.

LNG Bunkering Vessels

In the vast expanse of the maritime world, the rise of LNG (Liquefied Natural Gas) as a marine fuel marks a significant turning point. As the industry grapples with the challenges of GHG (Greenhouse Gas) emissions and the pressing need for sustainable shipping, LNG emerges as a beacon of hope.

Endorsed by the IMO (International Maritime Organization), LNG is not just another marine fuel; it represents a paradigm shift towards clean energy in the maritime sector. Bunkering vessels play a pivotal role in this transition, ensuring that ships can refuel with LNG efficiently and safely, no matter where they are in the world.

But why is there such a buzz around LNG? The answer lies in its potential to drastically reduce the industry’s carbon footprint. Unlike traditional marine fuels, LNG produces significantly fewer emissions, aligning with the global push towards a more sustainable future.

For those new to the concept, understanding the LNG bunkering basics is crucial. It’s not just about fueling ships; it’s about fueling them right.

As we delve deeper into the world of LNG bunkering vessels, we’ll uncover the intricacies of this clean energy source, its impact on the maritime industry, and why it’s rapidly becoming the preferred choice for ships worldwide.

Overview of the Current Fleet of LNG Bunkering Vessels

The evolution of the maritime industry towards more sustainable practices has seen a significant rise in the adoption of Liquefied Natural Gas (LNG) as a bunker fuel. Let’s delve into the growth trajectory and the current distribution of the LNG bunkering fleet.

Historical Growth

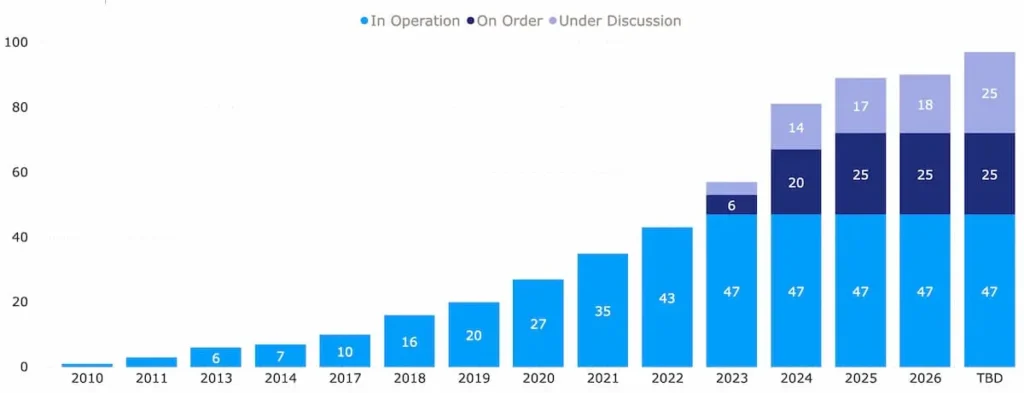

The journey of LNG bunkering vessels began modestly, with only a single vessel in operation in 2010. This number saw a steady rise in the subsequent years, reaching 43 vessels by 2022.

As of 2023, the number stood at 47 vessels in operation. Additionally, there’s a clear anticipation of a continued upward trend, with orders for 25 more vessels for 2026 and discussions underway for even more.

Distribution LNG fuelled fleet by type

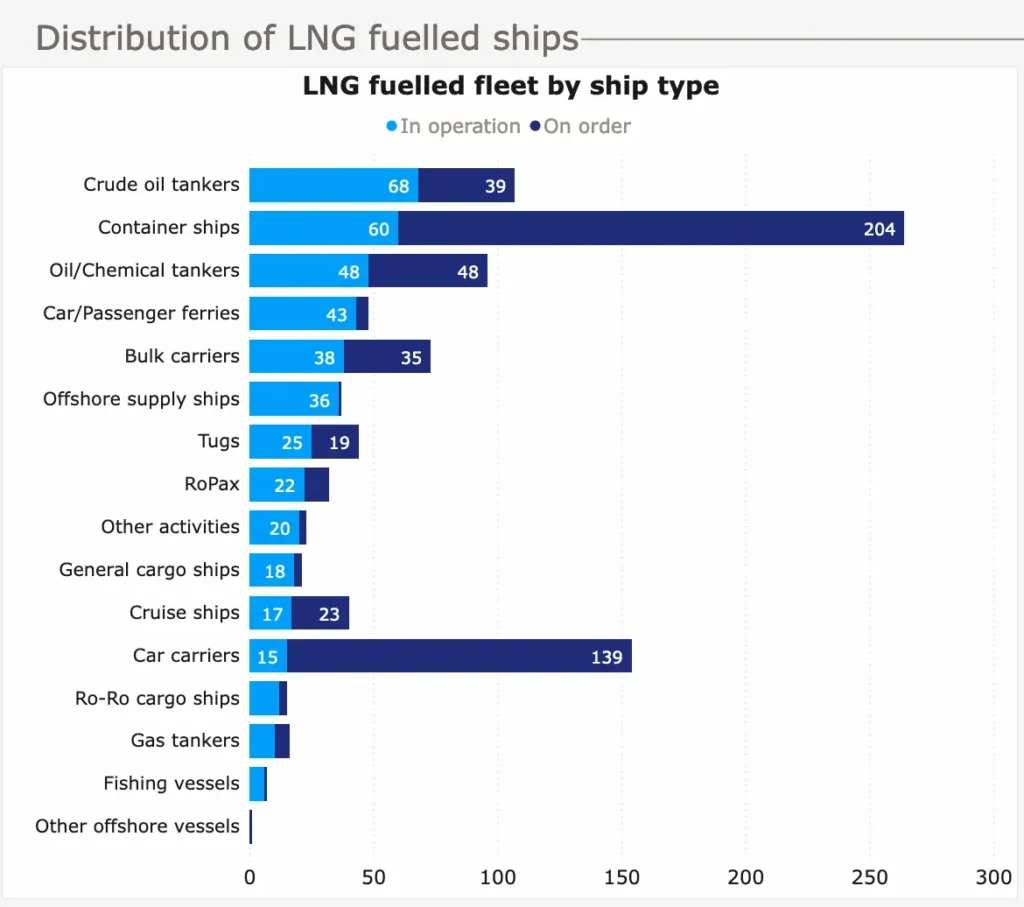

When we classify the LNG-fuelled vessels by ship type, the data reveals a diverse fleet. Crude oil tankers lead the way with 68 vessels in operations, followed by container ships (60) and oil/chemical tankers (48).

In the next 3 years, the situation will flip and the leading positions will be taken by container ships, Car carriers leaving Crude oil tankers on the third place only.

Notably, the car/passenger ferries and bulk carriers also contribute a significant portion with 43 and 38 vessels in operations, respectively.

The presence of LNG in niche ship types like RoPax, general cargo ships, and cruise ships indicates the industry’s broad acceptance of LNG as a feasible fuel alternative.

Tank Capacity Analysis

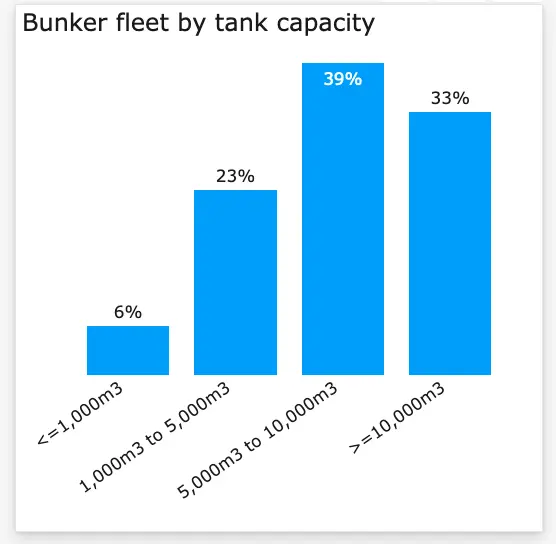

The distribution of LNG bunker vessels by tank capacity provides insights into the prevalent storage requirements in the industry.

The largest segment of the fleet (38.55%) falls within the 5,000m³ to 10,000m³ capacity range. However, larger capacities aren’t far behind, with vessels having a capacity of 10,000m³ or more constituting 32.53% of the fleet.

Smaller capacities, like those under 1,000m³, comprise 6.02%, highlighting a clear preference for medium to large-sized storage tanks in the current market scenario.

While there are currently 47 LNG bunkering vessels in operation globally, their number is deemed sufficient for the time being. However, a significant uptick in their count is anticipated by 2025, as ships using LNG fuel are expected to proliferate at a pace that outstrips the growth of LNG bunkering vessels and infrastructure.

The challenge in the industry revolves around defining an ideal tank size for these vessels. Large modern container ships, for instance, necessitate fuel volumes that allow them to traverse entire oceans, approximating around 6,000-8,000 cubic meters.

In contrast, car carriers usually refuel with volumes close to 2,000 cubic meters. Expert projections suggest that the average tank size, in the imminent years, will likely hover around 10,000-12,000 m³.

Highlighting the extremes, the present-day largest LNG bunkering vessel, operated by the Chinese, boasts a capacity of 30,000 m³. Meanwhile, at the other end of the spectrum, the Swedes command the smallest vessel with a modest 160 m³ capacity.

These variations in tank capacities underscore the diverse requirements of the maritime sector and present both challenges and opportunities for the industry. As ship types and operational needs evolve, so will the specifications of LNG bunkering vessels, attesting to the dynamic nature of this burgeoning sector.

LNG Bunkering Vessels List in 2024

| Ship name | Delivery year | Region of operation |

|---|---|---|

| Avenir Accolade | 2021 | America |

| Avenir Achievement | 2022 | America |

| Avenir Advantage | 2020 | Asia |

| Avenir Ascension | 2022 | Europe |

| Avenir Aspiration | 2021 | Europe |

| Bergen LNG | 2021 | Europe |

| Bunker Breeze | 2018 | Europe |

| Clean Canaveral | 2021 | America |

| Clean Jacksonville | 2018 | America |

| Coral Anthelia | 2013 | America |

| Coral EnergICE | 2018 | Europe |

| Coral Energy | 2013 | Europe |

| Coral Favia | 2010 | Europe |

| Coral Fraseri | 2019 | Global |

| Coral Fungia | 2011 | Europe |

| Coral Furcata | 2011 | Europe |

| Coral Methane | 2018 | Europe |

| Coral Nordic | 2022 | Europe |

| Coralius | 2017 | Europe |

| Dmitry Mendeleev | 2021 | Europe |

| FlexFueler 001 | 2019 | Europe |

| FlexFueler 002 | 2021 | Europe |

| FueLNG Bellina | 2020 | Asia |

| FueLNG Venosa | 2023 | Asia |

| Gas Agility | 2020 | Europe |

| Gas Vitality | 2021 | Europe |

| Green Zeebrugge | 2017 | Europe |

| Hai Gang Wei Lai | 2022 | Asia |

| Hai Yang Shi You 301 | 2022 | Asia |

| Haugesund Knutsen | 2022 | Europe |

| K. Lotus | 2022 | Europe |

| Kaguya | 2020 | Asia |

| Kairos | 2018 | Europe |

| LNG London | 2019 | Europe |

| New Frontier1 | 2017 | America |

| New Frontier2 | 2023 | America |

| Oizmendi | 2018 | Europe |

| Optimus | 2021 | Europe |

| Pioneer Knutsen | 2020 | Europe |

| Q-LNG 4000 | 2020 | America |

| Seagas | 2013 | Europe |

| SM JEJU LNG1 | 2019 | Asia |

| SM JEJU LNG2 | 2020 | Asia |

| Titan Unikum | 2023 | Europe |

| Titan Vision | 2023 | Asia |

| XIN AO PU TUO HAO | 2022 | Asia |

| Yidu inland river LNG bunker barge | 2014 | Asia |

Evolution of LNG Bunkering Vessels

The maritime industry, with its rich history and deep-rooted traditions, has always been a reflection of global economic and technological shifts. The story of LNG bunkering vessels is no exception, tracing a narrative of innovation and adaptation.

In the early days of shipping, vessels primarily relied on fuels like MGO (Marine Gas Oil) and HFO (Heavy Fuel Oil). These traditional fuels, while effective, came with a significant environmental cost, particularly in terms of sulfur emissions.

As global awareness about environmental conservation grew, so did the scrutiny on the maritime industry’s carbon footprint. This led to the introduction of the sulfur cap, a stringent regulation aimed at reducing the sulfur content in marine fuels.

This transition towards cleaner fuels was not just a regulatory mandate but a necessity for the industry’s sustainable growth. Enter LNG. As the world grappled with the challenges of climate change, the maritime sector began its journey of fuel evolution, moving from traditional fuels to the cleaner, more efficient LNG.

The growth of the LNG bunkering industry was not just a response to environmental concerns but a testament to the industry’s adaptability and forward-thinking approach.

Today, as LNG bunkering vessels sail across the world’s oceans, they symbolize the maritime industry’s commitment to a greener future, echoing the global call for sustainable practices and cleaner energy sources.

Key Features of LNG Bunkering Vessels

LNG bunkering vessels, with their specialized design and features, stand as marvels of maritime engineering. These vessels, tailored to cater to the unique requirements of LNG as a marine fuel, are equipped with a range of features that ensure efficient, safe, and reliable operations.

One of the primary features of these vessels is their cryogenic tanks. Designed to store LNG at extremely low temperatures, these tanks ensure that the gas remains in its liquid form, optimizing storage capacity and ensuring efficient transfers. These tanks are intricately designed, factoring in the specific properties of LNG and the challenges associated with its storage.

Another crucial aspect is the BOG (Boil-off Gas) management system. Given the volatile nature of LNG, managing boil-off gas is essential to ensure safety and minimize wastage. Advanced BOG management systems in these vessels ensure that any evaporated LNG is either re-liquefied or used as fuel for the vessel, optimizing efficiency.

Furthermore, the transfer systems in these vessels are designed for both efficiency and safety. Whether it’s a ship-to-ship transfer or refueling at a port, these systems ensure that LNG is transferred without any spillage or wastage. For a deeper dive into the technicalities of LNG vessel specifications, one can explore the intricate designs and systems that make these vessels truly unique.

Safety Protocols in LNG Bunkering

Safety, given the nature of LNG, is paramount in bunkering operations. Recognizing the potential risks associated with LNG transfers, the industry has put in place stringent safety protocols.

At the forefront of these safety measures are the safety barriers. These barriers, both physical and procedural, ensure that any potential hazards are identified and mitigated before they can pose a risk. Coupled with this is the emergency shutdown system, designed to halt operations immediately in the event of any anomalies.

Another crucial safety feature is the gas detection system. Given the flammable nature of LNG, these systems continuously monitor for any gas leaks, ensuring immediate response in case of any breaches.

However, safety is not just about equipment and systems. It’s also about the people operating these vessels. Comprehensive crew training for LNG ensures that every individual onboard is well-versed with the safety protocols, risk management strategies, and hazard identification techniques.

This human-centric approach to safety, combined with advanced safety equipment, ensures that LNG bunkering operations are conducted with the highest standards of safety and reliability.

Global Impact of LNG Bunkering

The maritime industry, with its vast reach and influence, plays a pivotal role in shaping global environmental and economic landscapes. The shift towards LNG bunkering has far-reaching implications, not just for the industry but for the world at large.

From an environmental perspective, the adoption of LNG as a marine fuel is a significant stride towards reducing the carbon footprint of global shipping. With the maritime sector accounting for a substantial portion of global greenhouse gas emissions, the transition to LNG can significantly mitigate the industry’s environmental impact. This shift aligns with global efforts to combat climate change, making the maritime sector a proactive participant in global sustainability initiatives.

Moreover, the ripple effects of this transition extend to coastal communities and ecosystems. Reduced emissions from ships mean cleaner air and healthier marine ecosystems, leading to improved quality of life for coastal populations and a boost in marine biodiversity.

Economic Implications of the Shift to LNG Bunkering

The economic ramifications of the maritime industry’s pivot to LNG are multifaceted. On one hand, the demand for LNG has spurred investments in infrastructure, from the construction of specialized bunkering vessels to the development of LNG terminals and refueling stations in ports worldwide. This has generated employment opportunities and has invigorated local economies, especially in regions emerging as LNG bunkering hubs.

On the flip side, the reduced reliance on traditional marine fuels has implications for the oil and gas industry. As ships transition away from fuels like MGO (Marine Gas Oil) and HFO (Heavy Fuel Oil), there’s potential for shifts in global oil demand and prices.

Furthermore, the initial investment required for ships to transition to LNG can be substantial. However, in the long run, the operational savings, coupled with potential regulatory incentives and the prospect of reduced carbon taxes, make LNG a financially viable option for many shipping companies.

In essence, while the shift to LNG presents challenges, it also offers opportunities for economic growth, innovation, and the development of new markets, solidifying the maritime industry’s role as a key player in the global economic landscape.

Future Trends in LNG Bunkering Vessels

As we navigate the waters of the maritime industry, it’s evident that the horizon holds promising developments for LNG bunkering vessels. The confluence of technology, environmental concerns, and industry needs is shaping a future that’s both exciting and challenging.

One of the most anticipated trends is the push towards decarbonization. With global emphasis on reducing carbon footprints, the maritime sector is actively exploring ways to further reduce emissions. While LNG already offers a cleaner alternative to traditional marine fuels, the industry is not stopping there. Research into even cleaner fuels and technologies is underway, ensuring that the maritime sector remains at the forefront of environmental conservation.

Another significant trend is the exploration of alternative fuels and hybrid systems. As the industry looks beyond LNG, there’s a growing interest in fuels like bio-LNG, hydrogen, and ammonia. Additionally, hybrid systems that combine LNG with other fuels or energy sources are gaining traction, offering the potential for even lower emissions and greater operational efficiencies.

However, the path ahead is not without challenges. As the industry evolves, there will be hurdles related to infrastructure, regulations, and technology adoption. Yet, these challenges also present opportunities. Opportunities for innovation, collaboration, and setting new benchmarks in sustainable shipping.

For those keen on understanding the future of maritime fuel, it’s a narrative of continuous evolution. From technological advancements to the emergence of new fuels, the landscape of LNG bunkering is set to witness unprecedented changes. At MaritimePage.com, we remain committed to chronicling these changes, ensuring that our readers are always abreast of the latest in green shipping and LNG bunkering innovations.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025