International maritime law mandates that all ships maintain certificates verifying compliance with critical conventions, such as the International Convention for the Safety of Life at Sea (SOLAS) and the International Load Line Convention. These documents cover essential systems, equipment, and structural aspects, ensuring they meet high safety and operational standards.

A survey is a structured inspection to confirm the functionality and compliance of a ship’s systems and equipment with international standards.

Conducted by classification societies and Port State authorities, these surveys uphold international maritime standards, ensuring that vessels operate safely and comply with both safety and environmental regulations critical to sustainable merchant fleet operations.

Ship Survey Types

Surveys are carried out either by Port States, Flag states, or organizations they empower to carry out the surveys on their behalf. The following are the types of surveys carried out on ships:

Initial Survey of the Ship

The Initial Survey is a one-time, comprehensive assessment conducted before a vessel enters service. Classification societies, acting on behalf of the flag state, perform this survey to ensure that all systems, structural elements, and equipment meet both national and international safety standards, particularly under SOLAS and MARPOL.

Key aspects of the Initial Survey include:

- Document Review: Verification of technical specifications, diagrams, and certifications.

- Structural and Machinery Inspection: Confirmation that materials, construction, and machinery match approved designs and meet safety requirements.

- Safety and Pollution Controls: Examination of life-saving equipment and pollution prevention systems in line with SOLAS and MARPOL standards.

The Initial Survey is essential for granting a ship its operational certificate, affirming its suitability for safe, compliant operations from the outset.

Annual Survey

The Annual Survey is conducted every 12 months to confirm that the ship remains in compliance with SOLAS and Load Line Convention requirements. Authorized by classification societies or other recognized entities, this yearly inspection checks essential systems and equipment to ensure continued safe operation.

Key areas inspected in an Annual Survey include:

- Hull Integrity: Examination of the hull condition and structural stability.

- Safety Equipment: Verification of life-saving appliances and firefighting equipment.

- Machinery and Electrical Systems: Ensuring operational integrity for navigation and safety.

- Pollution Prevention Controls: Inspection of systems to prevent pollution, as mandated by MARPOL.

This survey is mandatory to maintain the vessel’s certification and operational status under international law.

Periodical Survey

The Periodical Survey is conducted at set intervals, typically every 2-3 years, depending on the vessel type and flag state requirements. It serves as a mid-term inspection between the Initial and Renewal Surveys, mandated by SOLAS, MARPOL, and the Load Line Convention to ensure continued compliance.

Key components of the Periodical Survey include:

- Structural Inspections: Examination of the hull, bulkheads, and structural elements.

- Safety and Environmental Systems: Verification of fire suppression, life-saving appliances, and pollution controls.

- Mechanical and Electrical Checks: Ensuring primary systems are in optimal working condition.

Periodical Surveys are vital for renewing required certificates and confirming the ship’s seaworthiness for continued operations.

Renewal Survey

The Renewal Survey is required every five years, ensuring the vessel’s compliance with SOLAS, MARPOL, and Load Line Convention standards. This survey usually requires dry docking for a thorough inspection of underwater components and critical systems, ensuring long-term operational approval.

The renewal survey is an extensive inspection that often requires dry docking to allow a thorough examination of underwater sections, crucial for long-term operational approval.

Key checks during the Renewal Survey include:

- Hull and Underwater Structures: In-depth inspection of the hull, rudder, propellers, and other underwater components.

- Life-Saving and Safety Equipment: Ensuring compliance with current safety standards.

- Machinery and Cargo Systems: Assessment of machinery, cargo holds, and other essential systems.

- Pollution Prevention Measures: Detailed review of systems designed to prevent marine pollution.

The Renewal Survey is mandatory for the issuance of a new certificate, allowing the vessel to continue operations without interruption.

Special (Class) Survey

The Special (Class) Survey is required every five years by classification societies and focuses on verifying a vessel’s structural integrity and essential equipment. For older ships, or those with a history of incidents, classification societies may require more frequent inspections due to increased risks. The survey aims to confirm that the ship meets the classification society’s rigorous standards, particularly in areas that might be at higher risk due to age or wear.

Special Surveys include:

- Hull and Structural Assessment: Extensive checks on the hull, superstructure, and other load-bearing elements.

- Machinery and Safety Systems: In-depth review of machinery, safety equipment, and other critical operational systems.

- Damage and Repair Verification: Confirmation that repairs from past incidents meet class standards.

This survey is essential for maintaining the vessel’s classification and operational certification, especially for ships over 20 years old.

Intermediate Survey

The Intermediate Survey is conducted at the midpoint of a vessel’s five-year certification cycle, typically around 2-3 years after the Initial or Renewal Survey. This inspection is mandated by SOLAS, MARPOL, and classification societies to verify that the vessel continues to comply with safety and environmental standards.

During the Intermediate Survey, surveyors conduct a thorough check of:

- Critical Systems and Components: Examination of the hull, machinery, and electrical systems to ensure operational reliability.

- Safety Equipment and Pollution Control: Verification of fire-fighting equipment, life-saving appliances, and MARPOL-compliant pollution prevention systems.

- Structural Integrity: Inspection of primary structural elements to assess ongoing seaworthiness.

This survey allows shipowners to address any maintenance needs promptly, ensuring the vessel remains safe and compliant between Renewal Surveys.

Pre-purchase Survey

A Pre-purchase Survey is an in-depth inspection typically conducted before a buyer finalizes the purchase of a vessel. It is not legally required but is highly recommended to assess the ship’s condition and value. Classification societies or independent surveyors usually perform this inspection.

Key elements of the Pre-purchase Survey include:

- Structural Assessment: Evaluation of the hull, deck, and internal structures for signs of wear, corrosion, or damage.

- Machinery and Equipment Review: Inspection of engines, propulsion systems, and auxiliary machinery.

- Safety and Maintenance History: Review of maintenance records, operational manuals, and life-saving appliances.

- Seaworthiness and Value: Overall assessment of the ship’s condition and seaworthiness, aiding the buyer in understanding potential future maintenance or repair needs.

The Pre-purchase Survey provides the buyer with a comprehensive understanding of the vessel’s current state and anticipated future upkeep requirements.

Dry Docking Survey

The Dry Docking Survey is performed whenever a vessel is taken out of the water and placed in a dry dock for repairs or maintenance. Typically, this survey is required at least once every five years, often aligning with Renewal Surveys. It allows surveyors to inspect parts of the ship normally underwater, such as the hull and propulsion systems.

Key inspection areas in a Dry Docking Survey include:

- Hull and Coating Condition: Detailed examination of the hull’s surface, coating, and any signs of corrosion or damage.

- Propeller, Rudder, and Shafts: Inspection of these critical components to assess wear and alignment.

- Sea Valves and Openings: Ensuring watertight integrity and functionality of all underwater valves and openings.

- Hull Cleaning and Painting: Maintenance tasks such as cleaning marine growth and applying protective coatings.

This survey is critical for identifying potential structural or mechanical issues that may not be visible during standard in-service inspections.

Underwater Inspection in Lieu of Dry Dock (UWILD) and In-Water Survey (IWS)

The Underwater Inspection in Lieu of Dry Dock (UWILD) allows a vessel to undergo a comprehensive underwater inspection instead of a scheduled dry docking, subject to approval from the classification society and flag state. This inspection enables the ship to remain in service, minimizing downtime.

- Scope: UWILD includes thorough checks of the hull, propellers, rudder, and sea valves to meet the same standards as a dry dock inspection.

- Approval Requirements: Unlike the more flexible In-Water Survey (IWS), UWILD requires strict adherence to procedural controls and real-time verification by surveyors to be accepted as a dry docking substitute.

- In-Water Survey (IWS): IWS, while similar, generally involves less comprehensive inspections and is often used as an interim maintenance check rather than a full dry dock replacement.

These inspections are valuable tools for maintaining a vessel’s condition while maximizing operational efficiency and flexibility.

Condition Assessment Program (CAP) Survey

The Condition Assessment Program (CAP) Survey is a specialized inspection program designed primarily for older tankers and bulk carriers to assess their structural condition and suitability for continued service. CAP Surveys are typically required by cargo owners, oil majors, or other stakeholders who seek assurance of a vessel’s condition beyond standard classification requirements.

The CAP Survey evaluates the vessel’s condition based on a structured grading system, where each area (e.g., hull, machinery, structural components) is rated from 1 to 4, with 1 indicating excellent condition and 4 requiring immediate repairs. This system provides transparency to cargo owners and charterers.

Key Aspects of the CAP Survey:

- Purpose: To provide an in-depth evaluation of a vessel’s condition, particularly as it ages, through a structured grading system. This survey is critical for verifying the ship’s safety, reliability, and seaworthiness.

- Frequency: CAP Surveys are often conducted every 5 years, aligning with the vessel’s certification renewal cycle or as specified by the cargo owner or charterer.

- Scope: The survey covers structural areas, tanks, machinery, and critical operational systems, with each component graded to indicate its condition.

- Regulatory Context: While CAP is not a mandatory classification survey, it has become an industry standard, especially for tankers and bulk carriers over a certain age, and is commonly requested by oil majors and charterers to assess compliance with their quality standards.

The CAP Survey helps shipowners maintain credibility with charterers, ensuring that older vessels meet stringent safety and operational standards.

Port State Control (PSC) Inspection

A Port State Control (PSC) Inspection is a regulatory inspection conducted by Port State authorities on foreign vessels to verify compliance with international conventions, such as SOLAS, MARPOL, and the International Load Line Convention. PSC inspections are a critical safeguard to prevent substandard ships from operating and to uphold safety, environmental, and labor standards.

Key Aspects of Port State Control Inspection:

- Purpose: The main aim of PSC inspections is to ensure that foreign vessels entering the port meet internationally mandated standards for safety, environmental protection, and crew welfare. It serves as a secondary layer of enforcement, complementing the vessel’s flag state responsibilities.

- Frequency: PSC inspections are unscheduled and can occur whenever a ship calls at a port. However, certain factors, such as a ship’s age, past deficiencies, or high-risk profile, can increase the likelihood of inspection.

- Scope: PSC inspections cover a broad range of compliance areas, including:

- Structural Integrity: Ensuring that the hull, decks, and superstructure are in safe condition.

- Certificates and Documentation: Verifying that all essential certificates (e.g., SOLAS, MARPOL, Load Line, ISM Code) are current and valid.

- Safety and Life-Saving Equipment: Checking the condition and availability of life-saving appliances, firefighting equipment, and navigational aids.

- Crew Welfare and Working Conditions: Assessing compliance with the Maritime Labour Convention (MLC) for crew rights, living conditions, and safety.

- Pollution Prevention Measures: Ensuring compliance with MARPOL requirements for waste management, bilge water treatment, and ballast water management.

- Consequences of Non-Compliance: If deficiencies are found, the vessel may be detained, issued deficiencies that must be corrected, or even denied entry into port. Severe deficiencies can lead to ship detentions until corrective actions are taken.

PSC authorities follow targeting systems that prioritize higher-risk ships, including older vessels, those with previous deficiencies, or ships operated by flags with poor safety records.

Port State Control Inspections are vital to upholding international standards across the global maritime industry, ensuring that only compliant, safe, and environmentally responsible ships operate within territorial waters.

Load Line Survey

The Load Line Survey is a regulatory inspection under the International Load Line Convention to ensure the vessel is marked with accurate load lines, indicating safe loading limits and protecting vessel stability across varying sea conditions.

Load lines are markings on the hull that indicate the maximum depth to which a ship can be safely loaded in various water conditions, ensuring stability and safety during navigation.

Key Aspects of the Load Line Survey:

- Purpose: To ensure that the vessel’s load lines are marked correctly and comply with load line regulations, protecting the ship’s stability and buoyancy under different loading conditions.

- Frequency: Load Line Surveys are typically conducted annually as part of the Annual Survey, with more comprehensive checks occurring during the Renewal Survey every five years.

- Scope: Includes inspection of hull integrity, watertight closures, freeboard markings, and the condition of the hull plating around load lines.

- Regulatory Context: Mandated by the International Load Line Convention, this survey is enforced by the classification society and flag state, ensuring that vessels operate safely at approved load levels in various sea conditions.

The Load Line Survey is crucial for verifying a vessel’s compliance with stability standards, safeguarding it against potential overload or stability risks.

Damage Survey

The Damage Survey is conducted after a vessel sustains damage due to an incident or accident. This survey assesses the extent of the damage, and the quality of repairs needed, and verifies that the vessel can return to safe operation. It is usually performed by a classification society or independent surveyor.

Key Aspects of the Damage Survey:

- Purpose: To evaluate the impact of damage on the ship’s structure, equipment, or systems and to confirm that repairs meet classification and safety standards before the vessel resumes service.

- Frequency: Conducted as needed following any significant incident or accident, such as a collision, grounding, or severe weather damage.

- Scope: Focuses on damaged areas, including the hull, superstructure, machinery, and critical equipment. The surveyor also assesses repair quality to ensure compliance with class and safety standards.

- Regulatory Context: While not mandated by international conventions, classification societies require Damage Surveys to validate the safety and structural integrity of repaired vessels before re-entry into service.

The Damage Survey is essential for verifying that all repairs are conducted according to recognized standards, ensuring the vessel’s seaworthiness and compliance with classification requirements.

On/Off-Hire Condition and Bunker Survey

The On/Off-Hire Condition and Bunker Survey is performed at the start (on-hire) and end (off-hire) of a charter period to document the vessel’s physical condition and fuel levels. Charterers or shipowners typically request this survey to ensure transparency in the vessel’s condition and fuel usage.

There are two main parts to this survey:

- Condition Survey: Examination of the ship’s overall condition, including hull, cargo holds, and critical machinery, documenting any pre-existing damages.

- Bunker Survey: Measurement of bunker fuel (ship fuel) levels to calculate fuel consumption during the charter period for financial settlement.

This survey is essential for maintaining accurate records, and helping both parties resolve any disputes regarding the vessel’s condition or fuel usage.

Surveys for Ship Recycling

When a ship is scheduled for recycling, it undergoes several surveys to ensure that the process is safe and environmentally responsible. These surveys are mandated by the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships.

Key surveys for ship recycling include:

- Inventory of Hazardous Materials (IHM) Survey: Identification and documentation of hazardous materials onboard, which is essential for planning safe recycling operations.

- Pre-cleaning Survey: Assessment of the vessel for any operational waste, hazardous substances, or residues that require removal before recycling.

- Final Survey: Conducted immediately before the ship is recycled to confirm compliance with safety and environmental standards.

These surveys are crucial for managing hazardous materials and ensuring that the recycling process adheres to global environmental and safety standards.

Special (Additional) Survey

The Special (Additional) Survey is conducted on a vessel after significant repairs, modifications, or incidents that may affect its seaworthiness. Classification societies or Port State authorities typically initiate this survey, particularly for older vessels or those with a history of incidents.

Key aspects of the Special Survey include:

- Damage and Repair Verification: Inspection of areas that have undergone repairs to confirm adherence to safety and classification standards.

- Structural and Equipment Checks: Examination of the hull, superstructure, machinery, and equipment to assess overall safety and functionality.

- Crew Interviews and Maintenance Review: Review of maintenance records and crew interviews to evaluate the ship’s operating condition.

Special Surveys are often required for vessels over 20 years old or those deemed high-risk, ensuring they remain fit for operation despite aging or previous damage.

Draft Survey

The Draft Survey is a specialized survey that measures a vessel’s cargo load by calculating the ship’s displacement. This survey is widely used in the merchant shipping industry, especially for bulk carriers, to determine the exact weight of cargo loaded or discharged.

Draft Surveys are conducted before and after cargo operations for accurate loading and unloading calculations.

Key Aspects of the Draft Survey:

- Purpose: To calculate cargo weight accurately, which is critical for commercial transactions and maintaining stability during navigation.

- Methodology: Surveyors take draft readings at fore, aft, and amidships on port and starboard sides, measure water density, and apply correction factors for accuracy. Displacement values are calculated based on the draft measurements and the ship’s hydrostatic tables.

- Regulatory Context: While not required by international conventions, Draft Surveys are industry-standard for many cargo owners, charterers, and ship operators, especially in bulk trades.

Warranty Survey

The Warranty Survey is conducted to ensure that specific maritime operations—such as heavy lifting, loading of project cargo, or transport of oversized structures—are performed safely and in accordance with industry standards. Insurance companies and cargo owners often require this survey to reduce the risk of accidents or damage during high-risk operations.

Key Aspects of the Warranty Survey:

- Purpose: To verify that the loading, securing, transport, and unloading of cargo adhere to safety and operational standards. This survey mitigates risks associated with complex maritime operations.

- Frequency: Conducted as required, typically for high-risk cargo operations or when transporting project cargo.

- Scope: Includes inspection of cargo stowage, lifting procedures, lashing, and securing of cargo, as well as the vessel’s suitability for carrying the specific cargo. The surveyor also reviews operational plans to ensure they align with best practices and insurance requirements.

- Regulatory Context: Warranty Surveys are typically required by insurance companies or cargo owners rather than by international conventions, ensuring compliance with contractual and safety requirements.

The Warranty Survey provides assurance to all stakeholders that the cargo operation is prepared and executed safely, meeting the contractual obligations and insurance criteria.

Load and Lashing Survey

The Load and Lashing Survey assesses the proper loading, securing, and lashing of cargo to prevent shifting or damage during transit. This survey is essential for ensuring that cargo is stowed safely and will not compromise the vessel’s stability or safety during the voyage, especially for bulk or project cargo.

Key Aspects of the Load and Lashing Survey:

- Purpose: To confirm that cargo is loaded and secured according to safety guidelines and that it will remain stable and undamaged throughout the voyage.

- Frequency: Conducted before each voyage or cargo operation, especially when transporting heavy, oversized, or irregularly shaped cargo.

- Scope: Involves the inspection of cargo securing methods, including lashings, chains, stoppers, and dunnage. Surveyors ensure that the cargo is stowed in a way that maintains vessel stability and complies with loading standards.

- Regulatory Context: Required by cargo owners, charterers, and sometimes Port State Control to ensure safety compliance. It adheres to guidelines from the Code of Safe Practice for Cargo Stowage and Securing (CSS Code), as well as classification society standards.

The Load and Lashing Survey is crucial for safe transport, ensuring that cargo remains secure during transit and reducing the risk of accidents or cargo loss.

The Harmonized System of Ship Survey

The Harmonized System of Ship Survey and Certification (HSSC), established under IMO Resolution A.746(18), was designed to streamline the survey and certification process for ships. Introduced to reduce redundancy, the HSSC allows ships to consolidate required surveys and certifications into a single, coordinated timeline.

The harmonized system provides:

- Standard Survey Intervals: Surveys are conducted on an initial, annual, intermediate, periodical, and renewal basis as needed, with most certificates aligned on a five-year cycle.

- Flexibility in Survey Timing: Permits completion of Renewal Surveys within three months before certificate expiry without affecting validity.

- Certificate Validity Periods: Cargo ship certificates have a maximum five-year validity, while Passenger Ship Safety Certificates last 12 months.

- Extension Procedures: Allows certificates to be extended up to three months (or one month for short voyages) for journey completion.

The HSSC improves efficiency by synchronizing survey schedules, reducing the need for frequent port visits, and helping ships maintain operational continuity.

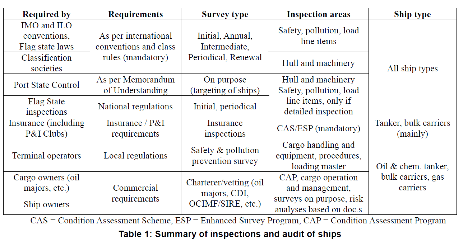

Current Survey Practices

The ship inspection system has evolved to include both mandatory and non-mandatory inspections. Mandatory inspections are based on international legal frameworks, including SOLAS and MARPOL, and are enforced by flag and Port States, often conducted by recognized classification societies.

In addition, non-mandatory (industry-driven) inspections may be required by:

- Insurance Providers: To assess risk and liability, such as by Protection and Indemnity (P&I) Clubs.

- Terminal Operators: To confirm vessel suitability for port facilities.

- Cargo Owners (Oil Majors, etc.): For quality and safety assurance.

- Shipowners: For routine assessments of their fleet’s operational condition.

This dual inspection system enables thorough oversight of vessel standards, ensuring the safe and compliant operation of merchant fleets.

| Survey Type | Mandatory/Non-Mandatory | Frequency | Governing Bodies/Requesting Entities | Specific Requirements |

|---|---|---|---|---|

| Initial Survey | Mandatory | Once, before entering service | Classification societies, Flag State | Comprehensive assessment to verify compliance with SOLAS, MARPOL, and Load Line requirements before operation. |

| Annual Survey | Mandatory | Annually | Classification societies, Flag State | Inspects hull, machinery, and safety equipment for SOLAS, MARPOL, and Load Line compliance. |

| Periodical Survey | Mandatory | Every 2-3 years | Classification societies, Flag State | Mid-term inspection for continued compliance with structural and safety standards under SOLAS and MARPOL. |

| Renewal Survey | Mandatory | Every 5 years | Classification societies, Flag State | Extensive inspection, often requiring dry docking, to renew vessel certificates under SOLAS and MARPOL. |

| Intermediate Survey | Mandatory | Midpoint of the 5-year cycle | Classification societies, Flag State | Verification of structural integrity and compliance with MARPOL, SOLAS, and other conventions between Initial and Renewal. |

| In-Water Survey (IWS) | Optional | As needed | Classification societies | Routine maintenance check of underwater areas, less extensive than a dry dock inspection. |

| Underwater Inspection in Lieu of Dry Dock (UWILD) | Conditional Substitute | Every 2-3 years or as approved | Classification societies, Flag State | Allows substitution of dry docking with an underwater inspection if stringent standards are met. |

| Pre-purchase Survey | Non-Mandatory | Before purchase | Ship buyers, Classification societies | Comprehensive inspection to evaluate vessel’s condition and value for potential buyers. |

| Dry Docking Survey | Mandatory | Every 5 years | Classification societies, Flag State | Inspection of underwater areas, conducted in dry dock for thorough examination of the hull and propulsion systems. |

| On/Off-Hire Condition and Bunker Survey | Non-Mandatory | At start and end of charter period | Charterers, Shipowners | Documents vessel condition and fuel levels at the beginning and end of a charter period for accuracy in settlements. |

| Surveys for Ship Recycling | Mandatory | Before recycling | IMO, Flag State | Includes hazardous materials inventory, pre-cleaning, and final survey for safe, environmentally sound recycling. |

| Special (Class) Survey | Mandatory | Every 5 years | Classification societies | Extensive survey to maintain classification, focusing on hull, machinery, and equipment, especially for aging ships. |

| Condition Assessment Program (CAP) Survey | Non-Mandatory | Every 5 years or as required | Cargo owners, Oil majors, Classification societies | In-depth survey for older tankers and bulk carriers, evaluating structural condition and grading quality. |

| Load Line Survey | Mandatory | Annually, with Renewal Survey every 5 years | Classification societies, Flag State | Ensures correct load line markings and compliance with International Load Line Convention to maintain stability. |

| Damage Survey | Conditional | As needed | Classification societies, Flag State | Conducted after incidents to assess damage and verify repairs meet safety standards before resuming operation. |

| Warranty Survey | Non-Mandatory | As required for high-risk operations | Insurance companies, Cargo owners | Verifies safety compliance for loading, transport, and unloading of heavy or oversized cargo. |

| Load and Lashing Survey | Non-Mandatory | Before each voyage | Cargo owners, Charterers, Port State Control | Ensures cargo is properly secured and stowed in line with CSS Code and industry safety standards. |

| Draft Survey | Non-Mandatory | Before and after cargo operations | Cargo owners, Charterers | Measures vessel displacement to calculate cargo weight for commercial transactions. |

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025