The burner boilers mix up fuel and air to make complete combustion and make a high degree of combustion efficiency.

The burner in a boiler is considered the most critical part because it supplies the thermal energy the boiler needs to heat the water for it to produce steam, which is then needed to heat mostly fuel and water onboard.

Mostly, the burner has a series of settings to make a firing more sustainable because if there is less air on the ratio, the combustion will be incomplete, fuels that are unburned will be moved over and more smoke will be produced. Meanwhile, too much air on the ratio would rather cool the furnace and the heat would be neglected.

Steam is vital onboard, for heating is needed to raise the temperatures of fuels and maintain their viscosity for the engine’s consumption. Furthermore, in order to produce sustainable steam, we must consider the operation of the burner so that it can give enough thermal energy and prevent some heat loss.

So, make sure to check always the fuel tip nozzle for any wear and obstructions as well as the damper mechanisms, and don’t forget to do some re-calibrations and maintenance of the burner.

How does a boiler burner work?

Burner devices are fitted with a fan that is made to produce high steady air pressure that is required to get an efficient ignition and good combustion in a modern combustion chamber. The amount of air that is needed for the amount of fuel that will be combusted is controlled by a servomotor.

Burner runs a series of steps before it is fired, these are:

Pre-ventilation

Mostly, all boilers run through a pre-ventilation period. During this period, the burner fan runs at full load to drive-away explosive fumes outside of the boiler to the exhaust chambers. With this, it helps prevent a further explosion from possible fuel leaks from the nozzle that evaporates inside when it is stopped.

Purging

During purging periods, the nozzle valve is flushed and is pre-heated. The oil temperature controller ensures enough temperature has been reached for fuel atomizing. This is to ready the burner for the ignition period.

Ignition

At the end of the purging period, the servomotor turns to the position of load ready for ignition. During this period, the oil pressure begins to affect the nozzle control circuit and the oil flows from the nozzle. The ignition begins when the oil spraying from the nozzle ignites from the spark between the ignition electrodes.

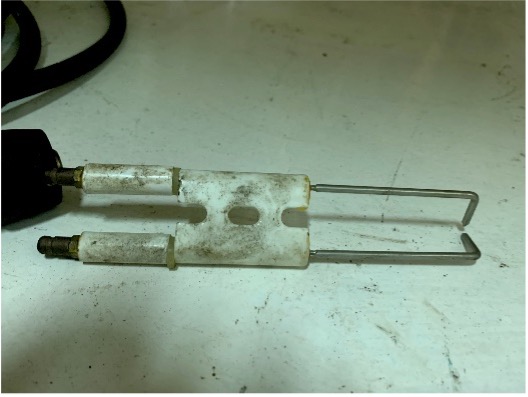

Sample of ignition electrodes onboard

Some type of burner uses a pilot burner for ignition, especially when using HFO (heavy fuel oil) as their fuel. The pilot burner uses MDO (marine diesel oil) to start an ignition then after a few seconds, the main burner sprays HFO along with atomized air and starts firing.

Afterward, the ignition pump stops along with the solenoid valve for the pilot valve to cut the diesel supply thus stopping the flame of the pilot valve. This is because MDO is easier to ignite than HFO.

Sample of pilot burners onboard:

Atomizing

During burner operation, a capacity controller is fitted along with the servomotor, which controls the air dampers as well as the oil regulators to give the load needed according to the capacity requirements.

The oil quantity to be burnt is regulated by means of the oil regulator by throttling the oil return flow. At partial load the oil regulators open and at full load closed.

Which burners are most effective in boilers?

Oil-fired burners are widely used on boilers as their means of producing thermal energy. These burners can burn both MDO (diesel) as well as HFO (heavy fuel oil) at a controlled temperature.

Viscosity and temperature of the fuel is the most important factor in producing efficient combustion, that’s why they should be monitored always because they affect the size of the oil particle that is produced at the burner nozzle.

Fuel with lower temperatures may result to have a larger size of droplets which will lead to poor combustion due to unburnt fuel which will further create smoke and soot. Meanwhile, fuels that have higher temperatures than normal will create very fine size of droplets which will lead to rapid fire near the nozzle tip.

What are the types of burners?

There are several types of burners that have been used on different boilers throughout the years. However, for marine boilers, these are the basic types of burners that are used:

Pressure jet burners

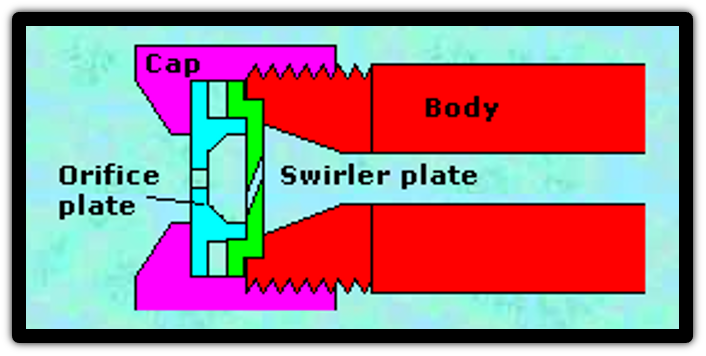

Burners’ main role is to atomize the fuel into fine droplets to achieve the desired combustion needed. For pressure jet burners, this is achieved by installing an orifice or a nozzle at the end of the pressure line.

The orifice of the burner comes at several diameters in order to sustain the required boiler load. Furthermore, the maintaining pressure of the fuel is typically within 7 to 15 bar, which also plays a part in a good atomizing process.

Advantages of pressure jet burners

- different variety of orifice diameter which can changed according to different boiler loads,

- can be fitted mostly to all types of boilers

- easy construction, and

- lesser maintenance cost.

Disadvantages

- it can’t sustain enough thermal energy needed by high load boilers

- nozzle usually clogs especially when using heavy fuel oil

- needs frequent maintenance

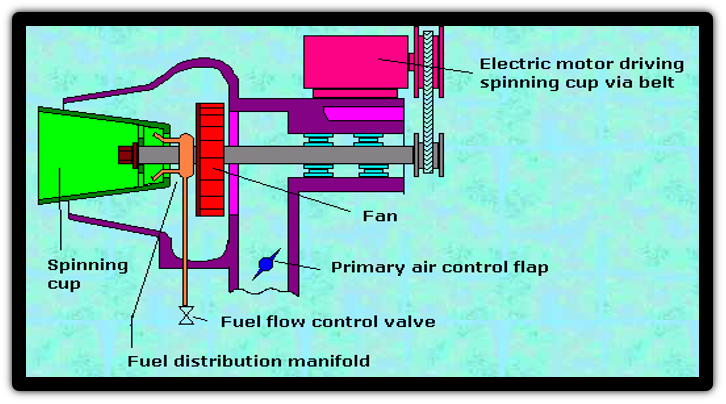

Rotary cup burner

Based on the name itself, rotary cup burners construction is made of a central tube and a rotating cone/cup. Fuel is supplied through the central tube, and as the fuel leaves the tube, it goes directly to a rapidly rotating cone which the fuel moves along.

Under a centrifugal force, the fuel film becomes thinner in its course as the circumference of the cup increases, thus producing atomized fuel as it leaves the tip of the rotating cone.

Advantages of rotary cup burners

- they can be of good use for the atomization of heavy fuel oils

- there is no high oil pressure on the line since it is dependent on the speed of rotation of the cup to produce atomized fuel

Disadvantages

- it is costly to maintain due to its complex construction

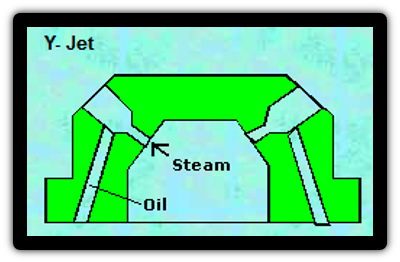

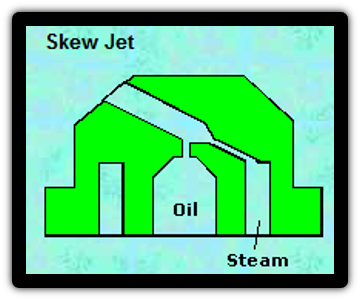

Air or steam-assisted atomizer

The oil inside the burner is sprayed along with the high-pressure air or steam to produce atomization. During starting, if steam is still not yet available, this burner uses air for atomizing. After the build-up of steam (usually 8 kilos and above steam), valves can be switched to use the steam for atomizing.

These burners are mostly equipped with pilot burners, that serve as an ignition for the main burner to fire. Pilot burners fire using diesel and they are used especially when using HFO because heavy fuel oils are very hard to start.

Advantages

- these burners are good for combusting HFO

- it has a robust construction, which may last longer than the other burner

- the air and fuel ratio can be adjusted by controller valves according to the load needed

- they can sustain enough heat to high-load boilers

Disadvantage

- combustion is dependent on air or steam

- since it is dependent to both air and steam, additional piping requirement for it to switch between the two means of atomizing.

What is boiler panting?

Panting usually occurs when there is a decrease of fuel oil supply when the air supplied is deficient or maybe the temperature of the fuel is too high resulting to vaporization on the burner tip.

When there is improper combustion due to low atomizing steam or air, or maybe less temperature of the fuel, there will be a sudden disturbance/vibration or yet the pulsating movement of the burner on the boiler.

As the pressure of the furnace will drop, the pressure of the gasses and smoke due to unburnt fuel will increase. This will signal the controller of the forced draft fan to open more and induce more air to aid the combustion process of the flame, which further burns the fuel residue that are not combusted

All types of burners consist of only one goal, to produce thermal energy to create steam production onboard. To avoid further delays in producing steam or more cost expenses, make it a routine to check and maintain the burner of the boilers frequently.

Be careful in cleaning the nozzle tip or the swirling blades of the fan for they need extra care in handling!

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025

Leave a Reply