One aspect of a ship that needs additional consideration during design and construction is the hull. In the development of naval architecture, hull designs have gone from cylindrical wooden shanks to steel columns over time. To provide higher structural strength, engineers have been improving hull designs regularly.

A variety of forces are working simultaneously on the hull since it is constantly in contact with water. Additionally, a hull needs to be very resilient and durable to avoid structural damage in the event of a collision or grounding. One aspect of a ship that needs additional consideration during design and construction is the hull.

To construct a ship’s hull, naval architects use a variety of techniques depending on the ship’s function and design. We shall examine the fundamental ship hull designs that are frequently employed in this post.

Types Of Drawings Used For Hull Construction

From the initial design to the final production phase, naval architects and engineers use different sets of drawings to model the complex 3D hull shape such that every aspect of it is available as a plan with which the design can be brought into reality.

We shall look into some of the most important drawings used for the construction of a hull.

The Lines Plan

The three simplest drawings of a ship are its lines plan, which depicts the main shape of its hull. It consists of the body plan, the waterlines or half-breadth plan, and the profile or sheer plan. The line plan only represents the 3D shape of the shape and does not include any construction details.

The line drawing comprises projections of the points where the hull and several planes cross. The planes are equally spaced in each of the three dimensions (x, y, z). The planes in one dimension will be parallel to the planes in the other two dimensions. The sets of planes are referred to as being orthogonal or mutually perpendicular planes.

Placing the ship inside a hypothetical rectangular box with sides that just touch the ship’s keel (baseline) and sides can help you understand how a “lines drawing” works. Three orthogonal projection screens will be based on the box’s front, side, and bottom.

These screens will be used to project lines. The intersection of the hull with planes parallel to each of the three orthogonal planes results in the projection of the lines.

Let us learn more about the three main drawings of the lines plan to understand more.

The Half Breadth Plan Or The Waterline Plan

Consider a hypothetical box. A base plane is a reference plane that is located at the bottom of the box. Typically, the base plane and keel are parallel.

Now, Imagine at regular intervals a set of planes parallel and above the base plane. Each plane will cross the hull of the ship at its intersections, forming a line. These lines, which are referred to as “waterlines,” are all projected onto the “Half Breadth Plan,” a single plane.

Every waterline displays the true shape of the hull from the top perspective at a slight elevation above the base plane, making it possible to use this line as a guide when building the ship’s framing.

The waterlines being discussed here have nothing to do with where the ship floats in reality. These waterlines are where a hypothetical plane above the base plane meets the ship’s hull.

This waterline, also known as the “Design Water Line or Loaded Waterline,” will be one plane above the base plane and correspond with the ship’s usual draft (or draught). The ship floats above this waterline. In designs, the design water line is frequently denoted by the letters “DWL,” and “LWL”.

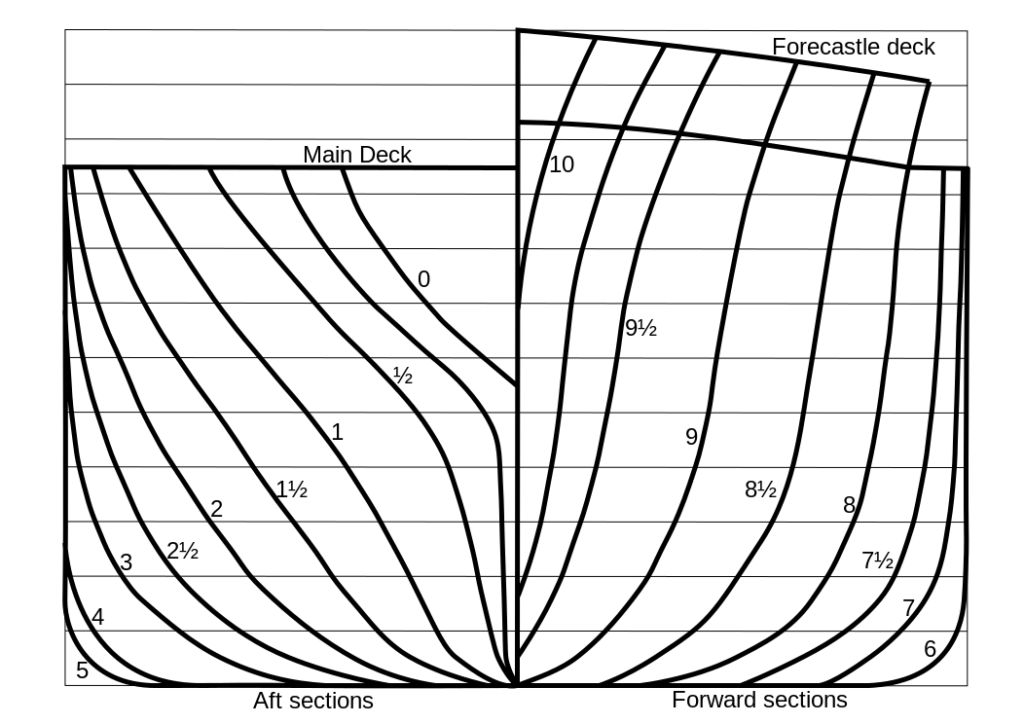

Body Plan

Stations or sections are the planes that run port to starboard parallel to the front and back of the hypothetical box. Typically, a ship is divided into 11, 21, 31, or 41 uniformly spaced stations. There will be more stations built as the ship gets bigger. An even number of equal blocks are created between an odd number of stations.

The symmetry of the ship is used to the body plan’s advantage. Because the opposite half of each section is identical, just half of each section is drawn.

By custom, the sections in front of the middle of the ship are drawn on the right side, while the sections in the back are drawn on the left. The amidships region of the body design is often depicted on both sides. The centerline is the vertical line in the middle that divides the ship’s left and right halves.

Each section line depicts the hull’s true shape from the front view at a specific longitudinal position on the ship, making it possible to use that line as a guide while building the ship’s transverse framing. At the points where each station plane intersects the ship’s hull, a curved line is created.

These lines are collectively referred to as “sectional lines” or “sections,” and they are all projected onto the “Body Plan” plane.

Sheer Plan Or Profile Plan

A centerline plane is a plane that passes right down the middle of the ship, parallel to the sides of the fictitious box. It travels from bow to stern. Imagined at regular intervals from the centerline are several planes parallel to one side of the centerline plane.

Each plane will cross the hull of the ship and create curved lines when it does. These lines are collectively referred to as “buttocks” and are all projected onto the “Sheer Plan.”

When viewed from the side and offset from the ship’s centerline, each buttock line reveals the true contour of the hull. This enables them to act as a template for the longitudinal structure of the ship.

The “profile” of the ship can be seen in the centerline plane as a unique buttock. The sheer line aboard a ship is the inspiration behind the name of the sheer plan. The upward longitudinal curvature of a ship’s deck is known as the sheer line. The vessel’s attractive aesthetic quality is due to its sheer line.

Shell Expansion Plan

This shell expansion plan provides details about the shell platings and how they are to be arranged so as to form the 3D shape of the hull. The ship’s hull shape is depicted as a three-dimensional surface in two dimensions. It is created using the ship’s line plan, with the contour lines built straight on the baseline to reflect the length of the ship.

On the length of the baseline, the contour lines on the lines plan are positioned at corresponding stations denoted by corresponding frame numbers. The shell expansion outline is created when a continuous line connects the ends of the vertical lines on the baseline.

The surface is then appropriately marked with parallel lines that are both vertical and horizontal, and they are aligned such that they exactly match the number of strakes that make up one-half of the hull surface.

Construction/production plan

The production plan is used to provide the production engineers and fabricators with the full details with which they can make the design a reality.

The production drawings help in enabling the full construction of the hull in a sequential format that best aligns with the build processes. The production drawings and information are basically a detailed explanation of the 3D Hull model. This comprises 2D drawings, welding schedules, structural assembly, plumbing, mechanical, hull outfitting, electrical, and HVAC 3D and CNC data.

Summary

Hull construction is both a design and production-oriented complex process which is one of the main functional parts of a ship that determines its various characteristics such as stability, sea keeping, and so on. The design and construction drawings provide the engineers and naval architects with a detailed plan with which they can make the design a reality.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025