Engine room watchkeeping is a continuous way for the watch to monitor and attend to the engine room and be able to rectify and troubleshoot problems that may occur anytime. Unfortunately, this is only applicable to conventional ships in which UMS or Unattended or Unmanned Machinery Space system is not yet installed.

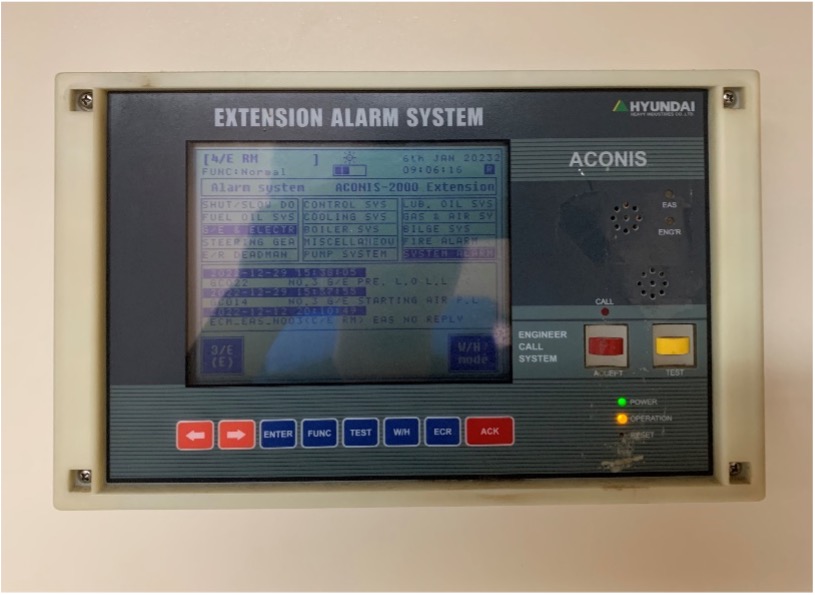

UMS is an automated system onboard that sends any malfunction from the engine room to the cabin of the duty engineer through the extension alarm system. This extension alarm system is also located in some various spaces inside the accommodation such as the mess room, gym, smoking room, etc.

In most ships, UMS is activated between 1700H to 0800H, so any alarms during that time will be attended to by the duty engineer. Furthermore, when the alarm needs assistance or concerns about the safety of the ship, and/or the duty engineer is in doubt about the decisions to be made, he/she will notify the chief engineer immediately.

In all cases, before the duty engineer switches to UMS mode, he/she must take a good check in the engine room and will also have his rounds around 2300H or before he/she takes their sleep.

In addition, if ever the alarm was not acknowledged by the duty engineer for some reason, the alarm will continue until it will alarm all cabins and spaces with an extension alarm system. In that way, the other engineer can check on the alarm to avoid any undesirable incidents happening.

Further in this article, we will discuss what to check in the engine room before the UMS will be activated and the essential requirements for UMS ships.

UMS Watchkeeping And Alarm System

UMS watchkeeping is like you a duty but inside your cabin or simply called “cabin duty”. Unfortunately, before you’ll have a good night’s sleep, there are plenty of things that you need to check during your rounds and maintain throughout your duty.

Here are the things that need attention during your rounds.

Dead Man Alarm System

First of all, before the duty engineer plans to enter the engine room, the latter must call the bridge and inform them how long will they stay inside the engine room. The duty officer on the bridge will take note of this and will call the engine within 30 minutes of intervals to check the status of the duty engineer. After this, before entering the engine room, activate the dead man alarm system on the entrance and/or on the ECR.

Example of dead man alarm and signal column onboard:

Once the dead man alarm system is activated, this will run continuously and must be acknowledged by the duty engineer by pressing the reset buttons found on any signal light column 10 minutes inside the engine room.

Through this, the dead man alarm system gives a safeguard to the duty engineer because once this is not acknowledged by the given time due to some particular reasons, the alarm will continuously sound to the extension alarm system of each cabin notifying that there is something wrong inside the engine.

Freshwater Hydrophore Tank, Cascade, Expansion Tanks, Fresh Water Generator

During rounds, always make sure that the water level of hydrophore, cascade, and expansion tanks is in the normal water level range. Once there is an abrupt loss of water inside cascade or expansion tanks, check for any steam or water leakage inside the engine room, especially the main engine and the generator. In addition, check also the freshwater generator for any flooding inside the evaporator space as well as its salinity ppm.

Air Compressors, Generator And Main Engine Sump Tanks

Also, checking for the oil level of the sump tanks of these pieces of machinery for the oil helps to avoid friction and lubricate the insides of the engine. Fill oil if necessary. Moreover, always make sure that the idle generator is on standby mode and the engine is on bridge control.

Provision Refrigiration Unit, Air Condition Unit, ECR Air Conditioner

The air conditioner gives comfort to the crew to have a good night’s sleep so always check for the belts, oil on the compressor, and the temperature and pressure of the refrigerant. This goes also for the provision ref unit.

Take a good inspection also of this machinery for this keeps the temperature of the food and provisions onboard. Furthermore, check also for any abnormalities on the ECR aircon to prevent the electronics and automation inside the engine control from any moisture.

Air Bottles To Drain/ Air Driers

The air reservoirs should be pressurized up to 30 bars. Always check the pressure switch of the main compressor to ensure that the reservoirs have sufficient pressure. In addition, don’t forget to drain the air reservoir from any water accumulation inside the tank. Don’t forget to drain also the air drier and make sure that the drying/cooling system is operational to have a moist-free control air supply.

Bilges Level And High-level Alarms Are Operational

Don’t forget to pump up bilges to avoid alarms at night due to high levels. Also, make sure that all high-level alarms are functional and it is not reposed.

Sludge, Overflow, And Oily Bilge Tanks Are At A Minimum Level

It is normal for sludge to rise up in level especially when purifiers are running. This goes also to the oily bilge tank if the main engine is running.

Meanwhile, the overflow rises casually due to backwash filters and some fuel leaks on the main engine. So, make sure that they are far from the maximum level to avoid high-level alarms and overflowing at night.

Fire Alarms And Smoke Alarms Are Operational And No Fire Zones Are Isolated

Fire and smoke alarms are very important onboard for they notify when there is an immediate fire in the engine room. So, make sure that the fire alarm system is operational and that no fire zones are isolated. Also, check the water valve that supplies the water mist if this is open. This is usually connected to the freshwater tank onboard.

General Routines During Rounds In The Engine Room

In your rounds, check also:

- Fuel oil purifiers – adjust the parameters when needed

- Fuel oil service and settling tanks – maintain the desired level and temperature that is necessary for the consumption of the engine. Also, don’t forget to drain them as well for they accumulate water inside the tank.

- Auto-backwashing filters – check the differential pressure between the inlet and the outlet.

- Pumps – make sure to set to standby mode for those pumps that are not in use

- Composite boilers and auxiliary boilers – check if they are switched to auto mode so they can start and stop when needed to and maintain the desired steam pressure

- Lastly, check the workshop for any plugged items such as an electric grinder or electric heater. Check also the welding machine if it is turned off and the fire alarm is switched on.

The Essential Requirements For Ums Ship

In order for ships to sail in UMS system, there are some requirements that need to be present onboard for it to work.

For a detailed list of requirements you can read and download one of the top ship class societies – Lloyds register Overview and find LR Code, but below are the requirements for UMS in ships:

Fire Prevention And Precaution

Under this field, the arrangements for the fire and smoke detection should be placed in the incinerator area, boiler area, generator, purifier room, and above the main engine. Aside from the smoke and fire detection, an oil mist detector and bearing temperatures must be installed on the main engine to be able to notify in case of any abnormalities in the system.

Example of oil mist detector onboard:

Automatic Fire Detection

Fire detection onboard must be fast and accurate. It should be placed carefully in places where fire and smoke can be detected quickly.

Fire Extinguishing System

Aside from the water mist system and hand extinguishers, there must be a fire station where a fire extinguishing system (high expansion foam, CO2 system, etc.) can be activated remotely inside the room. Along with this, fire pumps and quick-closing valves for fuel and vents should also be located inside the fire station.

Alarm System

Extension alarm systems should be operational and audible inside the cabins of each engineer and other accommodation spaces such as the mess room and smoking room. Make sure to test this weekly in order to know if they are still operational.

Protection Against Flooding

Bilge wells should have-high alarm levels and an operational auto start/stop of the bilge well pumps if the float switch is activated. A bilge pump long run alarm must be installed as well in order to know that the bilge pump’s pumping capacity is less than the water accumulation onboard.

The bridge should have full control of the engine’s speed and thrust and its limiters. Aside from this, the ship navigation bridge should have a monitor as well just like in the ECR in order to know the parameters of the main engine. An emergency stop should also be available at any cost to prevent any further incidents that may happen.

Automatic start of emergency system emergency generator should be in service in less than a minute in case of a blackout. Furthermore, emergency generators should be tested weekly and be started both in battery and hydraulic to know that it is operational. Also, check for the level of the marine gas oil that supplies the emergency generator as well as the lube oil on its sump tank.

To summarize, if all requirements are met, UMS system can be granted on ships that complied with it. Moreover, UMS system is a marine automation system onboard a ship that gives the engineers an advantage on rest periods compared to the conventional way of engine watchkeeping.

Unfortunately, there are still areas that need to be checked and monitored before activating the UMS and during the duty engineer’s night rounds. Furthermore, make sure that the key points and parameters are visited and maintained in order to have a good night’s sleep.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025