Bedplates are the one that supports the whole weight of the engine. It is located at the lowermost part of the engine and takes most of the load when it comes to weight. Moreover, it also supports the crankshaft of the engine and holds it in its exact position.

Accordingly, the bedplate is responsible also for fastening the engine to the tank top of the ship, thus transmitting the propeller thrust to the ship structure to be able to move and sail.

Engine bedplates must be flexible and robust enough to endure the heavy sag and hog of the ship structure to which it is attached.

In addition, taking care of bedplates should be properly done. Check for any corrosion especially when it is fitted at the tank tops where water and oil can be in contact with the bedplate.

Aside from corrosion, check also for any cracks and any loose bolts that hold down the engine. Keep it a habit to put marks on the bolts and nuts to know if they are moving or slowly loosening.

What is a bedplate made of?

Engine manufacturers (especially on large engines) mostly rely on cast or prefabricated steel to make engine bedplates. They always carefully choose the kind of material to use. More often, they check and test the material to be low-carbon steel with a maximum carbon content of about 0.23%.

For small engines, their bedplate is made of cast iron which has characteristics of reducing vibrations to avoid cracks during further use of the engine.

Bedplates that are made from cast iron or mixed with prefabricated steel are quite durable. It can absorb heavy impact and deform without any fracture. Moreover, they are also flexible and can take longitudinal stress without tearing it apart.

Bedplate construction

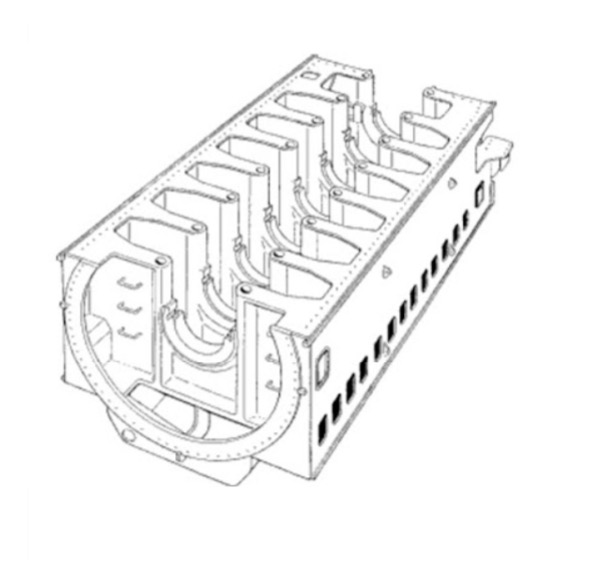

Mostly, bedplates are made of two longitudinal girders which have the same length as the engine it is supporting. Between these two longitudinal girders, there are transverse girders that are connecting them which are made to position the main bearing and run the crankshaft in a perfectly aligned manner.

The construction of the bedplate must be rigid enough to support the weight of the rest of the engine. In addition, bedplates may snap or crack when the ship flexes either by hogging or sagging if they are not cast very well.

Common problems with marine engine bedplate

Bedplates may encounter several problems as they are delivered to shipyards and installed on ships. That’s why a routine inspection must be carried out in order to raise the problem and immediately find solutions.

- Incorrect welding

Repairs for bedplate include welding. Check the welding if they are too deep or too shallow and might cause further problems during sailing.

- Corrosion

Corrosion may arise on bedplates because mostly it is in contact with water and oil, for it is located on the tank tops. Constant checking must be done to avoid serious damage to the engine.

- Loose bolts and nuts

Always check the bolts and nuts on the bedplate. Make it a habit to put marks to know if the nuts or bolts are slowly moving over time. Check whether the bolts and nuts are from the frame or from the ones holding onto the structure of the ship.

- Cracks

Constantly check for any cracks around the bedplate, or inside the crankshaft chamber if the ship is on standstill. Always pay attention to the bearing pockets, longitudinal girders as well as the transverse girders that are connecting them, and the base of the main bearings.

Bedplate functions

The bedplate is responsible for supporting the dynamic load of the running gear, the weight of the stationary engine, block, and frame, and most especially the crankshaft and keeping it aligned.

Furthermore, it is also responsible for fastening the marine engine to the ship’s structure in order to transmit the propeller thrust to the ship. It also collects lubricating oil and transfers it to the sump tank of the engine for recirculating using the main lube oil pumps.

It is very vital to keep a regular check of the bedplates of the engine. Check for any corrosion or cracks. Moreover, find a remedy immediately once any corrosion is noticed or any cracks to avoid further damage.

We must remember always that bedplates should be maintained properly for they are the foundation of the engines. Failure to keep the bedplates properly might end up having a reduction in engine efficiency due to heavy vibrations and misaligned crankshafts.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025