A waste oil incinerator is equipped onboard so that sludges that are accumulated can be burned and incinerated in order to lessen the volume of sludges in an environmentally way as well as comply with the latest IMO regulations.

Also, it can be used to burn garbage that is produced throughout the voyage. However, you can’t introduce glass, bottles, cartridges, or other solid materials that can not be burned.

Moreover, don’t put the wet solid waste inside for more than an hour before starting to avoid a sudden increase in temperature inside the furnace which may cause thermal problems on the furnace walls and thermocouples.

A rising level of sludge onboard can be caused by faulty purifiers or any fuel leaks in the engine room collected from bilges, and this is a burden for the engineers for they will need to find a way how to keep all the accumulating sludges.

Fortunately, an incinerator is introduced to lessen the sludges and other garbage onboard by burning them. Also, with incinerators, the owners or charterers can save money by hiring a barge to take the sludges to shore. However, there are still some regulations that are needed to follow in using the incinerator onboard.

Ship incinerator regulations

According to IMO, the regulations for shipboard incineration are divided into two parts. Regulations 16.1 – 16.4 covers onboard incineration in general and hence are potentially applicable to all ships meanwhile regulations 16.6 – 16.9 are specific only to incinerators installed on ships constructed on or after January 1, 2000, or to units installed on existing ships on or after that date.

- Regulation 16.1 – requires that incineration is only undertaken in equipment designed for that purpose

- Regulation 16.2 – prohibits incineration of certain materials and therefore can be seen as complementary to the MARPOL Annex V requirements in respect of the processing of ship-generated garbage.

- Regulation 16.3 – incineration of PVC or polyvinyl chlorides are prohibited unless the incinerator is approved with certificates from IMO in accordance with MEPC 59(33), MEPC 76(40), or MEPC 244(66)

- Regulation 16.4 – states that while incineration of ship-generated sewage, sludge, and sludge oil could alternatively be undertaken in main or auxiliary boilers, it is not to be undertaken within ports, harbors, or estuaries.

On the other hand

- Regulation 16.6 – require that incinerators installed on ships constructed on or after January 1, 2000, or units that are installed on existing ships on or after that date are to Type Approved in accordance with the resolution.

- Regulation 16.7 – requires that these incinerator’s operating manuals are to be maintained onboard

- Regulation 16.8 – requires that correct training must be given for the operation of the incinerator

- Regulation 16.9 – requires that the temperature of such incinerator must be achieved in order to ensure complete incineration inside the furnace chamber.

Working principles of waste oil incinerator

Burning waste oil

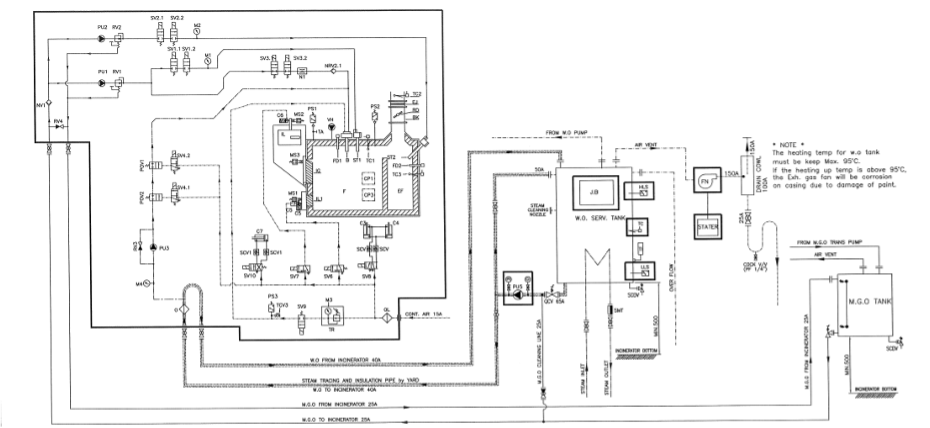

Before waste oil is burned inside the incinerator, it is preheated first on the waste oil settling and service tanks (some ships don’t have settling tanks) to evaporate the water so that it can be burned.

- Start of the incinerator – upon starting, the process timer, flue gas fan, and D.O burner blower will automatically start.

- Purging – after pressing start on the incinerator, the flue gas fan will automatically start to purge the unburnt gasses inside the furnace to avoid explosion.

- Preheating – after the purging time, the D.O. burner 1 and 2 will start simultaneously to preheat the furnace and bring it up to 650oC (for some incinerators, the burner 1 will start at 400oC depending on the settings)

- Feeding of waste oil – once the furnace temperature reaches 650oC, the waste oil burner will feed up the waste oil, and the D.O. burner 2 will stop. Meanwhile, the D.O. burner 1 will stop when the furnace temperature reaches 850oC. After this, only the waste oil burner will be firing the waste oil at an optimal temperature ranging from 900-950oC

- Temperature control – on times when the waste oil can’t maintain the furnace temperature due to some problems, the D.O. burner 1 will automatically start/stop at 850oC to keep up with the furnace temperature.

- Stopping of the incinerator – during the stopping of the incinerator, the waste oil burner will stop supplying waste oil and the flue gas fan will continue running to cool down the furnace chamber in a controlled manner.

Burning solid waste

Before introducing solid waste, make sure to check the garbage thoroughly. Also, don’t overload the incinerator with garbage, there is a standard quantity of load per charge during burning solid waste.

Moreover, don’t feed the following solid waste inside the furnace chamber

- Annex I, II, and III cargo residues and related contaminated packing materials.

- Polychlorinated biphenyls. (PCBs)

- The garage, as defined in Annex V of MARPOL 73/78, contains more than traces of heavy metals

- Refined petroleum products containing halogen compounds.

- Sewage sludge and sludge oil either of which are not generated onboard the ship

- exhaust gas cleaning system residues.

- and closed containers or aerosols for they are explosive kinds of materials

Failure to observe the below instructions can result in substantial damage to burners and thermocouples.

The sequence for the burning of solid waste is almost the same for the waste oil, except on solid waste, the waste oil burner will not start and the feeding of solid waste will be fed through the sluice door.

Operating Instructions Preparation

Before starting the incinerator, please check the following they are completely opened or closed.

1. Open the supply valve for compressed air

2. Open all supply and return valves for diesel oil

3. Make sure that the ash and sluice doors are closed.

4. Make sure that W.O is available in the W.O tank, preheated, and reached the temperature of 60℃ or more but not less than 90oC

5. Make sure that diesel oil is available in the diesel oil tank

6. Remove ashes and garbage that may cause possible combustion before the incinerator starts, and confirm the cleaning state of the main air entrance for combustion.

Waste Oil Burning

1. When the main switch is turned on, the WASTE OIL MODE is settled automatically. For only solid waste burning, the model should be changed to SOLID WASTE MODE. However, when the WASTE OIL MODE is settled waste oil and solid waste can be burnt together.

2. Check the alarm messages on the display screen by touch panel.

3. Activate the START-STOP switch to the START position on the control panel.

4. Most incinerator is operated automatically by PLC. If any abnormal alarm occurred during operation, kindly rectify the cause of the abnormal alarm and reset the alarm by touching the alarm display on the touch panel and starting again.

Solid Waste Burning

1. Make sure that the mode is settled on SOLID WASTE MODE

2. Check the alarm messages on the display screen by touch panel.

3. Activate the START-STOP switch to the START position on the control panel.

4. Most incinerator is operated automatically by PLC. If any abnormal alarm occurred during operation, kindly rectify the cause of the abnormal alarm and reset the alarm by touching the alarm display on the touch panel and starting again.

What are the types of waste oil incinerators?

There are two types of incinerators that are used onboard.

Horizontal Burner Type

The horizontal burner type has a burner arrangement similar to a horizontal fired boiler. The burner is horizontal to the combustion chamber or the furnace. However, due to its arrangement, the ash and non-combustible materials remaining at the end of the operation must be cleaned manually.

Vertical Cyclone Type

The burner on this incinerator is mounted at the top and the waste to be incinerated is supplied from the top as well. Moreover, a rotating arm device is equipped to optimize combustion and remove ash and slug from the surface.

Vital parts of the incinerator.

These are the important parts of the incinerator that needs inspection frequently.

- Furnace – check for cracks and collect the cracks frequently

- Flue gas fan – check the impeller regularly for any cracks on the impeller fan

- D.O. burner – check and clean the filter regularly

- Waste Oil burner – clean the swirler and the atomizer for any sludge and slug build up

- Waste oil Settling tank – with regular intervals, clean the settling tank to keep the evaporation of water from oil to maximum

- Waste oil Service tank – drain for water to ensure good combustion inside the furnace

- Thermocouples – check regularly to keep the temperatures on real time reports

During incineration, it is very vital to monitor the exhaust temperature and the furnace temperature. Having a high temperature may melt the metal inside and damage the furnace meanwhile with a low temperature, incineration may not be complete and efficient and may build up sludge formation inside. Fortunately, there are a series of interlocks that activates when this situation happens.

Moreover, make sure that your thermocouples are working properly to know exactly the temperature inside the furnace. In addition, always clean the furnace and remove slugs and ashes whenever possible.

Also, clean the swirlers of the burners and check if there is no obstruction on the air passage for atomizing of waste oil.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025