Have you ever seen a boat at a boat show or even in a marina where there are no outboard motors or propellers mounted when you look at the back of the boat? Consequently, how do these boats move without any of these?

These boats employ water-jet propulsion systems and are situated at the stern of the ship, close to the water. The system draws water in, processes it, and then sends it out through an aftmost nozzle at a high velocity to move the ship forward, which also can be used for steering and moving astern.

Trawlers, tugboats, private vessels, and smaller coast guard and naval ships are better suited for its use. Let’s go into more detail about the background, basic principles, various parts, and advantages and disadvantages of water jet propulsion systems.

How Does Water Jet Propulsion Work?

In 1661, Toogood and Hayes were the first to consider employing water as a source of power, suggesting that a central water channel may be utilized to generate propulsion. The idea underwent several adjustments before it was widely adopted and applied to commercial vessels, eventually leading to the ultimate design that is currently in use.

Newton’s Third Law, which asserts that every action has an equal and opposite reaction, serves as the foundation for the water jet system’s operation. The vessel is propelled forward by a reaction force created by the fast water ejection from the water jet system’s aft nozzle. A suction duct on the underside of the vessel feeds water straight into the main gear.

Although a higher number of ducts might improve the power generated, which is needed in large vessels, the majority of vessels only use one duct. The system’s primary processing unit is where the fluid entering the inlet is directed. The vessel can be stopped in the event of any obstruction brought on by debris close to the inlet until the obstruction is cleared. Other processes can backflush the inlet and move the trash.

What Are The Different Components Of A Waterjet Propulsion System & Their Function?

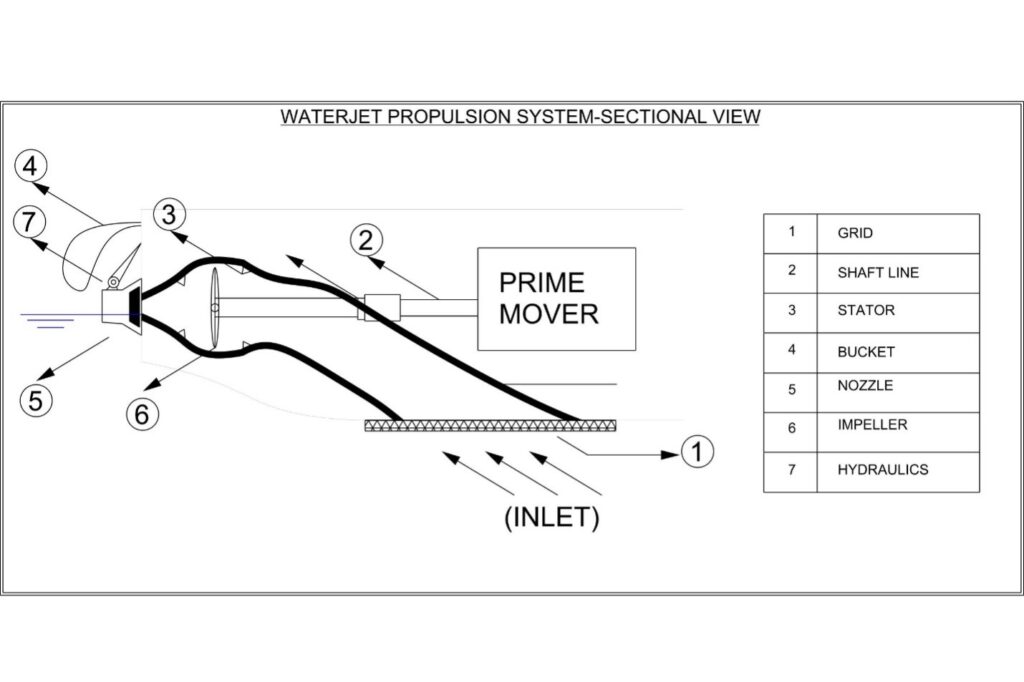

The main components of a water jet propulsion system are as follows,

- Impeller

The water will be at rest before suction, and therefore the incoming water to the motors will be comparatively low-energy fluid. This fluid needs to be transformed into a high-energy fluid to provide enough thrust. This is done by utilizing blades to create a little turbulence. A combination of an impeller and stator powers the blades.

This turbulence generates enough pressure, which is released as a high-pressure jet from the nozzle as a result of fluid mechanic responses. A shaft that houses the impeller is propelled by an onboard motor. The stator, which rotates the blades, is linked to it.

The impeller-stator configuration can be conceptualized as an airplane engine that rapidly increases the outlet velocity of air entering the turbine. The main drive shaft, which is coupled to the motor using reinforced bearings and connectors, rotates the impeller shaft.

- Nozzle

The fluid leaving the system is directed by the nozzle, which is situated at the rear of the unit. The steering wheel in the ship’s bridge is coupled to a swivel mechanism that controls it.

On most ships, the swivel motion lasts between 1500 and 1800 rpm. The vessel can move in reverse or make turns while in reverse thanks to a crucial part known as the astern deflector or bucket.

- Bucket

The bucket hydrodynamic shape is intended to gently reroute flow in the direction opposite to that which is used to provide the forward thrust. Depending on the desired steering maneuver, it can be raised or lowered such that it fits over the nozzle’s mouth with the help of hydraulics.

- Motor

There are two main sources used to power the unit’s moving parts:

hydraulics for the deflector operation and an onboard motor for the impeller shaft.

To prevent any kind of pollution in the event of an oil spill, the hydraulics, which are typically oil-based, are stored inside the hull of the ship.

Multiple access panels are spread out throughout the unit length to allow access to the different parts of the vessel. To open the system safely, the entire device must be switched off and completely stopped before doing so.

The unit is installed on specific structures that can divert and absorb the output forces because of the significant vibrational shocks and forces generated by the propulsion system. To properly disperse the force without producing hazardous point loads, it is directed into the substantial hull surface area.

- Stator

Stators are mounted to increase the efficiency of the incoming water by helping it maintain a specific direction after passing from the impeller to produce thrust.

What Are The Pros And Cons Of Waterjet Propulsion?

The following can be considered as the main advantages of waterjet propulsion systems when compared to conventional systems.

- Speed:

Small craft speed is crucial, and water jet-powered boats may go at speeds of up to 40 knots even in choppy waters. This is on par with and frequently exceeds customary industry norms.

The water jet system is quite tiny and can generate a significant amount of power in a relatively small space. This makes it a viable option for vessels with limited room

- Cavitation

Conventional propeller blades typically need to rotate at very high RPMs to produce enough thrust to travel at high speeds. The edges of the rotating propeller blades are then subject to a dynamic pressure difference with the surrounding medium. Due to the cavitation phenomena, this leads to the edge disintegrating.

Cavitation is brought on by water that rapidly evaporates along the surface of the blade, creating micro bubbles that harm the blade’s edge. Metal can be quickly worn through by this process, which also causes the vessel to move inexplicably.

Although hydrodynamic blades are also used in water jet systems, the dynamic pressure difference between the internal machinery and surrounding fluid is less. As a result, cavitation’s effects are greatly diminished. As a result, the system operates for a longer period.

- Draft

A shrouded construction protects the propeller blades from any unintentional contact with the high-speed blades. In comparison to traditional blades that are not shrouded, it is therefore safer. The fact that the complete assembly does not have to be submerged is another benefit of using water jets.

Unlike water jet systems, which only require the inlet to be immersed, typical systems require the complete blade and shaft assembly to be submerged to function which causes additional drag forces.

- Maneuvering

Since steering occurs practically instantly, water jet propulsion is much simpler to maneuver. This is a result of the hydraulic systems’ quick response time in swiveling the exit nozzle.

Water jet-powered vessels can do a full 3600 turn when stationary, unlike conventional vessels that need a bigger turning radius. Additionally, turns may be performed considerably more quickly by just giving the water jet more throttle. As a result, steering and navigation are much quicker and more effective.

- Gearbox

The absence of a gearbox is another advantage of water jet systems. While this offers a greater degree of control in propulsion systems that use regular engines, water jet systems do not require it. This is because only one gear mode is used and no rotating component’s torque needs to be changed.

The impeller, which is coupled to a fundamental rotational coupling, is the only rotating part of the system. As a result, water jet systems require maintenance and replacement of minor components.

- Stealth

Finally, compared to conventional propulsion, water jets make less noise from a military perspective. Reduced SONAR signatures and physical noise are the results of this. This is extremely useful for military-grade vessels that can travel at great speeds undetected by SONAR and other devices. This is partly caused by the assembly’s shrouded architecture, which reroutes and redistributes noise.

The main drawbacks of waterjet propulsion systems can be stated below,

- Cost

The biggest drawback of water jet systems is their substantial upfront expenses. The parts and equipment involved with this technology, unlike conventional propulsion systems, are still much too expensive to be incorporated into all vessels. Additionally, because of the specialized nature of the process, installation and maintenance costs can be high.

As a result, the majority of boat captains and owners choose to choose less expensive options. Water jet systems also have the limitation that they can only be applied to small and medium-sized vessels. This is because only vessels of these sizes can create enough thrust using normal equipment sizes. The propulsion systems would also need to be correspondingly bigger for larger vessels.

- Manufacturing

It is just far too expensive to carry out this type of manufacturing; it is not that it cannot be accomplished shortly. Additionally, it takes specialized tools that are still under commercial entities’ research and development to build components that are similar in size to conventional propellers. Due to reduced production costs, we can anticipate a gradual rise in the number of vessels using water jet propulsion shortly.

Summary

Most high-speed vessels worldwide employ waterjet propulsion, which is an effective form of propulsion. You can assess whether your boat needs water jet propulsion by looking at two key parameters: the operational parameters and the performance output.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025