Imagine reducing the shipping industry’s carbon footprint by a significant margin while also saving on fuel costs.

How, you ask? Welcome to the future of sustainable shipping – Rotor Sails.

These engineering marvels employ the Magnus effect to generate propulsion, offering a green alternative in an industry traditionally dominated by fossil fuels.

Our in-depth exploration of this innovative wind propulsion technology will cover everything from its scientific principles to real-world applications, impact on sustainability, and future projections. Join us as we sail into a greener tomorrow!

What are Rotor Sails?

Rotor sails are innovative wind propulsion devices installed on ships, utilizing the Magnus effect to enhance their energy efficiency and significantly reduce fuel consumption and emissions.

They are tall, spinning cylinders designed to capture wind energy and convert it into a forward thrust. The process begins when wind meets the spinning rotor sail, which accelerates the airflow on one side and decelerates it on the other, creating a pressure difference. This pressure disparity then generates a lift force perpendicular to the wind direction, providing an additional forward thrust to the ship.

Rotor sails stand out for their ability to deliver greater thrust force per square meter of sail area compared to other wind propulsion technologies, making them a promising solution in the pursuit of sustainable shipping. By implementing rotor sails, ships can minimize their reliance on fossil fuels, leading to lower operating costs and reduced environmental impact.

Their practical design includes an end plate for optimizing aerodynamic efficiency and a control panel for manual operation. Additionally, many rotor sail systems come with automated features that can monitor wind speed and direction, adjusting the rotational direction and RPM for optimal fuel savings.

The introduction of rotor sails to the maritime industry marks a significant step towards greener, more sustainable shipping practices. As the world grapples with the pressing need to reduce carbon emissions, rotor sails offer a viable path to an eco-friendly future in the shipping sector.

Named after their inventor, Anton Flettner, a German aviation engineer, rotor sails are ground-breaking wind propulsion systems that have been revolutionizing the maritime industry since their conception in 1920.

Rotor sails are designed to augment vessel efficiency by considerably reducing fuel consumption, bunker costs, and harmful emissions. They stand out from other wind propulsion technologies due to their unique ability to generate a significantly higher thrust force per square meter of sail area.

What Is The Magnus Effect?

Ever wondered why a tennis or golf ball curves during its flight path? The scientific reason behind this is the Magnus effect.

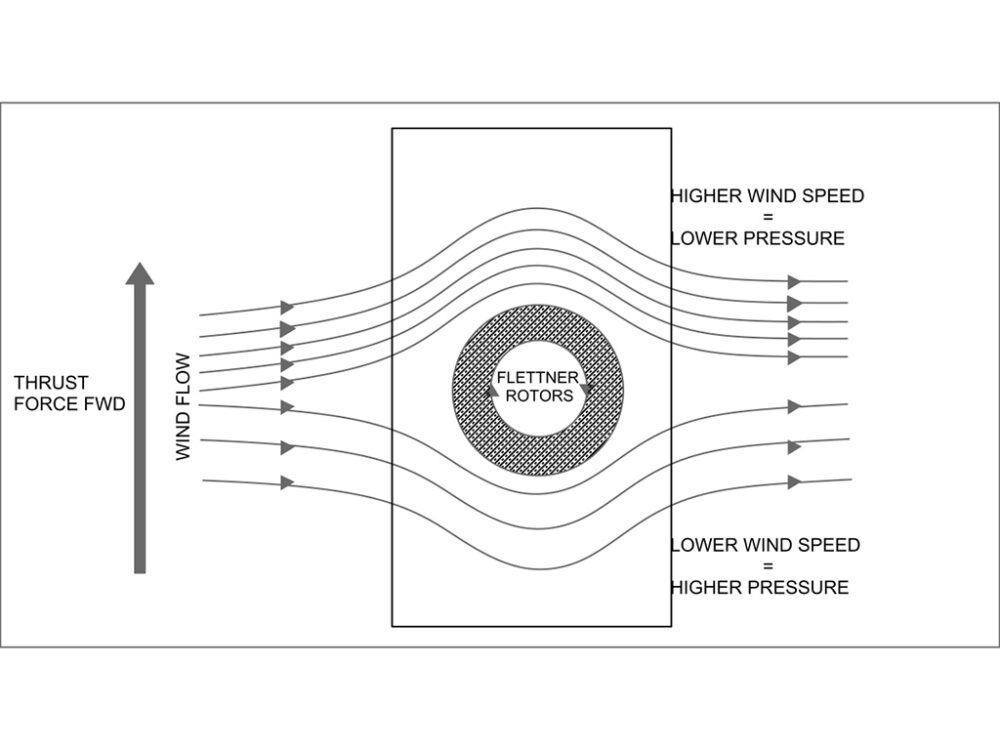

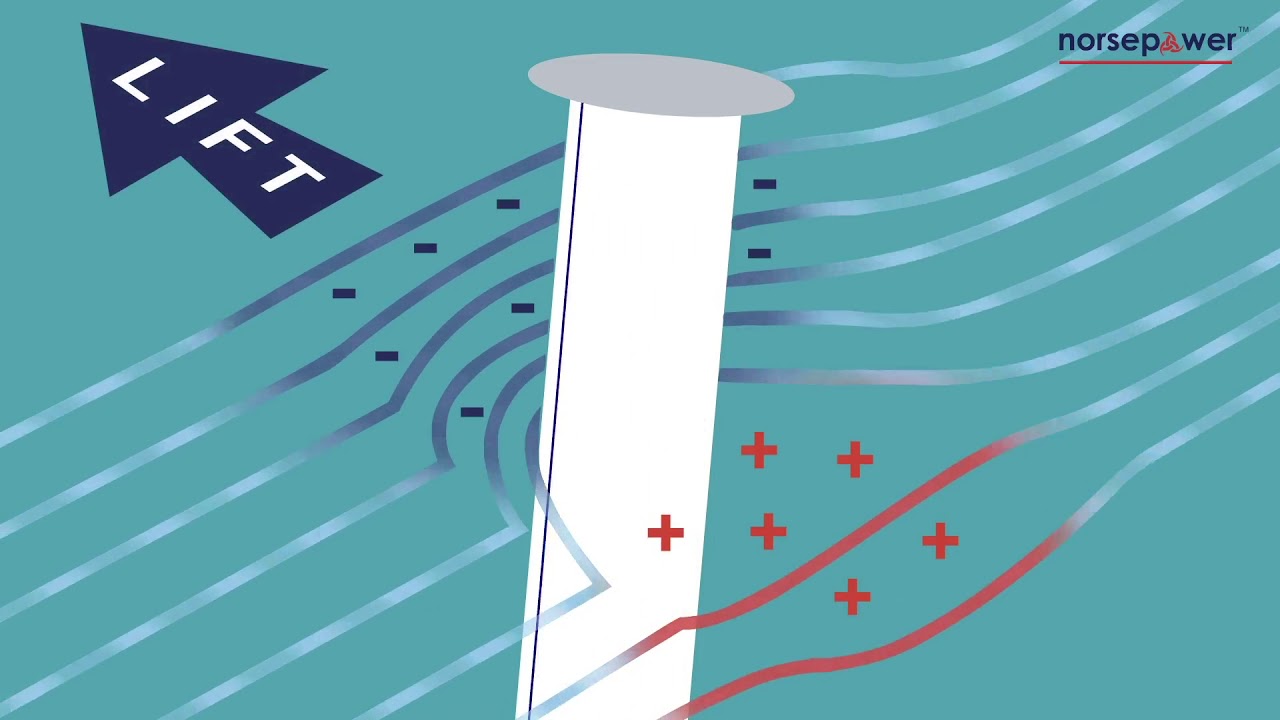

Magnus effect is when wind meets the spinning rotor sail, the airflow accelerates on one side of the rotor sail and decelerates on the opposite side creating a pressure difference.

Thrust is produced by the rotation of the sails in an airflow, which results in a pressure differential on the rotor’s aft and front surfaces. This thrust force is determined by wind angle and speed; the greatest thrust is produced when the wind direction is directly from the beam.

In operation when the rotor is switched on and starts rotating in presence of wind, the change in the speed of airflow results in a pressure difference which creates a lift force that is perpendicular to the direction of wind flow. This provides the ship with an additional forward force which reduces the engine’s fuel consumption.

How Does The Rotor Function?

There is an end plate fitted on the rotor which is used to optimize its aerodynamic efficiency. The crew has control of the rotor sails from the control panel on the bridge, also some systems can automatically monitor the wind and speed direction to determine the optimal rotational direction and RPM values which thereby maximizes the fuel savings for the vessel.

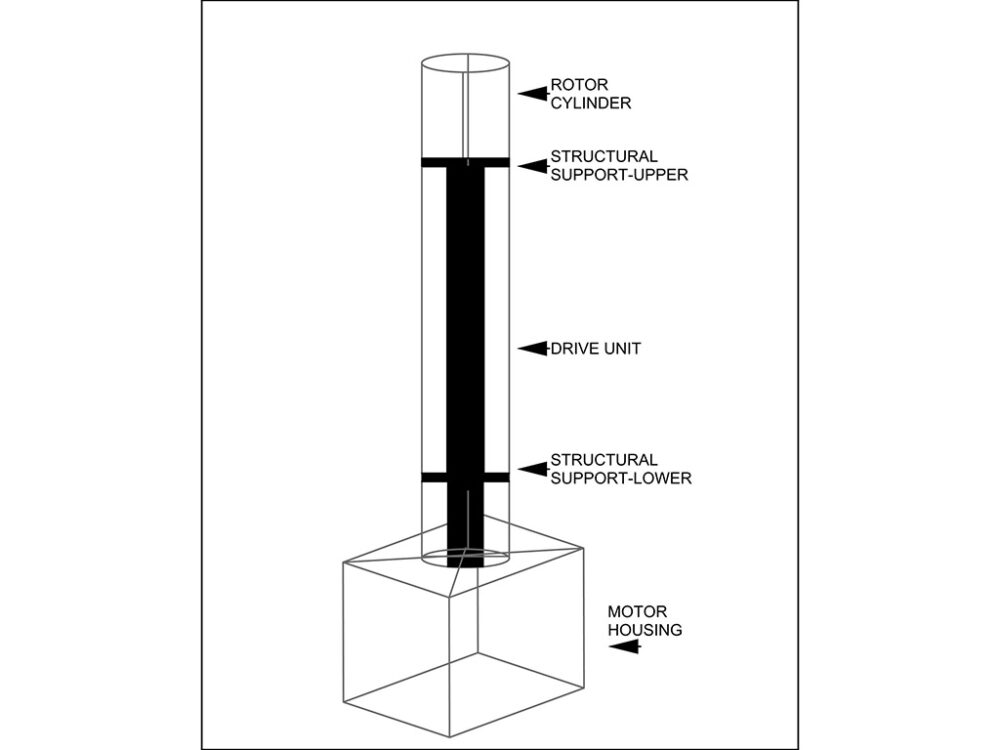

The rotor sails are mounted on vessels’ tailored foundations which also house a variable drive motor that can control the speed and direction of the rotor.

Flettner rotors are vertical cylinders that spin and generate lift forces due to the Magnus effect. These lift forces support the overall thrust forces acting on the hull for propulsion thereby reducing the loads on the main engines.

The total number, size, and location of rotor sails depend on the following factors,

- Available deck space

- Location of the structural members on the deck

- Vessel operation parameters and functions

What Are The Benefits Of Rotor Sails?

Most rotor sail manufacturers make sure that the rotors are designed and certified in line with the norms of the world’s main classification societies, assuring compliance with the highest maritime quality requirements.

The main benefits of rotor sails are ship performance and environment improvement, lightweight and flexibility, endurance, safety and compatibility, and versatility.

- Lightweight – Rotor Sails are made of the most modern composite structures and the most advanced manufacturing process to come up with lightweight yet strong materials to ensure exceptional performance while adding as little weight as possible. A sturdy steel tower at the center of the Rotor Sail securely transfers all loads into the ship structure.

- Endurance – By Class Requirements, rotors are intended to endure the most severe weather conditions as they stand very high above the main deck. Rotors can be designed for high seas and winds to withstand up to 35m/s (70kts). Some automated rotor sails automatically shut down in harsh situations that exceed their working limits. Reefing is not necessary, as it is with other wind technologies.

- Compliant with regulatory bodies – A 5-30% reduction in hazardous emissions such as CO2, SOx, and NOx benefits the environment while also assisting vessels in meeting regulatory requirements and objectives. Rotor Sails have a favorable influence on a newbuild vessel’s EEDI score and can give a path to compliance with the forthcoming 2025 Phase 3 standards, as well as improve possible operational indicators for retrofit installations (e.g. EEXI and CII).

- Performance benefits – Annual economic savings potential of 100 000 – 200 000 EUR per Rotor Sail under global average wind conditions. Typical average fuel savings of 5-20% per ship.

- Environment Benefits – The biggest Rotor Sail type has an annual average savings potential of roughly 300-350 kW. Annual fuel savings of around 300-400 tons. A 900-1200 ton decrease in yearly CO2 emissions.

- Movable – Sails may be redeployed between vessels based on operational needs, giving owners confidence in the lifetime of their investment and ensuring return.

- Safety and compatibility – Rotor Sails are appropriate for a wide range of vessel types, including newbuild and retrofit, Bulk Carriers (geared and gearless), Tankers, LPG and LNG Carriers, Ferries, and RoRo ships.

Rotor Sails Technical and Materials

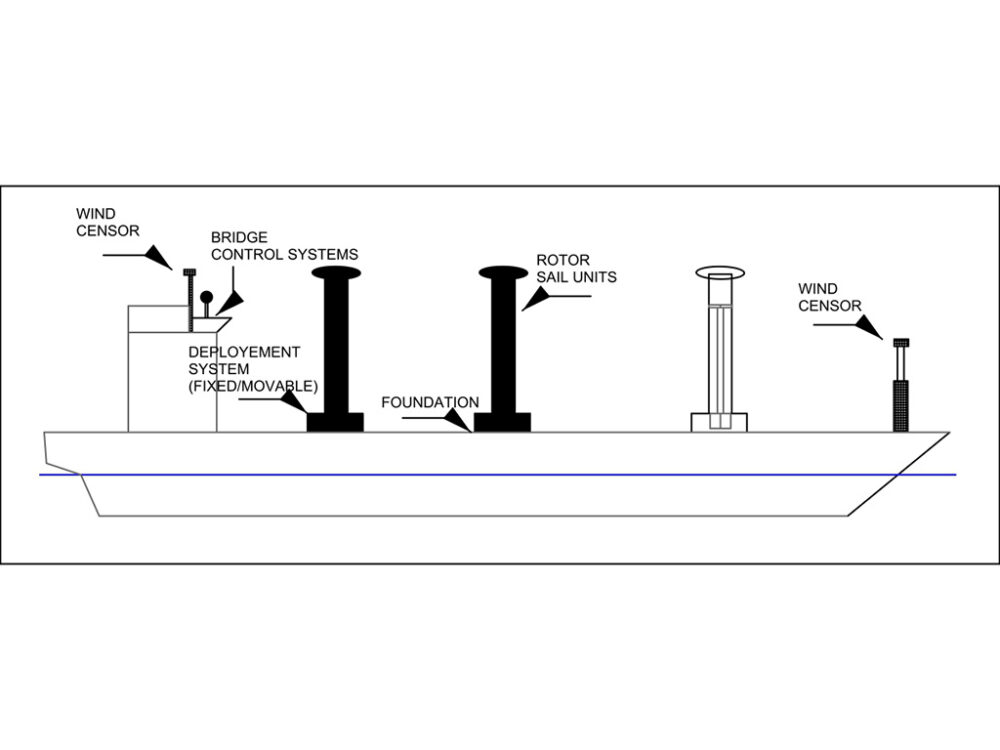

The Rotor Sail System is made up of the Rotor Sail, the Foundation, the Deployment System (if needed), wind sensors, and the Electrical and Control System. The following diagram depicts the position of the equipment.

The “Rotor” (the cylindrical, revolving section), the Tower, the Upper, and Lower bearings, and the electrical motor are the four basic components of our Rotor Sails. The “Rotor” is composed of lightweight composite material, while the Tower is made of steel columns.

The material selection is based on guaranteeing that the Rotor Sails operate well in all-weather situations. with the use of advanced composite like carbon fibers, the rotor sail systems are often less than 0.1% of the vessel’s deadweight.

Rotor Sails Controls And Electronics

A Control Station for the Rotor Sails is positioned on the bridge. This automatically regulates the speed and direction of the Rotor Sails while also monitoring the system’s performance and status. With automatic speed and direction setting, equipment monitoring, and safety shutdowns, the rotor sail control system is designed to maximize performance while minimizing crew involvement.

The electrical input power needs of the Rotor Sails vary with Rotor speed, which is affected by wind speed. When operational, the average power input of one Rotor Sail is approximately 40% of the rated power of the motor. A Rotor Sail with a 75kW motor, for example, would utilize 30kW on average.

Leading Rotor Sail Technology Providers

The following are a few of the major industry-leading companies that provide rotor sail technology and have successfully installed them on different kinds of vessels.

NORSEPOWER

A company named NORSEPOWER which is a leading sail technology provider has already installed rotor sails on different types of cargo ships such as tankers, dry cargo, and passenger vessels. Norsepower’s Rotor Sail system is the first complete commercial mechanical sail that has been third-party confirmed. The completely automated control system detects favorable wind conditions and operates the Rotor Sails with no intervention necessary from the crew.

The company has recently installed two 35m high world-first tiltable rotor sails, which allow the vessel plying in height-resisted routes to benefit from this technology to save fuel. The range of cost for a Flettner rotor varies from $1 000 000-$4 000 000 depending on the size and utility.

Anemoi

This company was started in 2007 to combat the global emissions from the shipping industry and to come up with a design solution that could revolutionize the industry. From the period 2008-2014, they started working on the Flettner rotor technology and even developed a full-scale model for testing and trials.

At present, they deliver clients with outstanding design solutions which include rotor sails that can be retractable and even removable which gives the owner flexibility in different operational conditions.

Hyundai

Hyundai, based in South Korea, has been working on a new rotor sail design to help in environmentally friendly shipping throughout the world. This is gaining popularity in the maritime sector as a feasible method for reducing carbon emissions. When in use, this new system is said to reduce carbon emissions and fuel consumption by 6% to 8%.

Hyundai stated that its design “improves the stability of the drive system compared to the belt method of existing commercial products by applying the reduction gear method to the driving part connecting the electric motor and the rotor.”

The system has been named the Hi-Rotor, and Hyundai expects to undertake land demonstrations with it by the end of 2022, after having their Rotor Sail system Approved in Principle by the Korean Register of Shipping.

Rotor Sails Summary

The rotor sails are efficient solutions in terms of reducing fuel consumption and emissions and can have a huge role in decarbonization in the maritime industry. Shortly, we can find more vessels that implement the rotor sail technology making them more efficient.

What are Rotor Sails and how do they work?

Rotor sails are wind propulsion devices on ships. They utilize the Magnus effect to enhance energy efficiency, converting wind energy into forward thrust and reducing fuel consumption and emissions.

What is the Magnus Effect and how does it apply to Rotor Sails?

The Magnus effect explains the curve of spinning objects in flight. In Rotor Sails, it creates a pressure difference when wind meets the spinning sail, generating a lift force and additional forward thrust.

What are the benefits of using Rotor Sails?

Rotor Sails enhance ship performance, are lightweight and flexible, endure severe weather conditions, and comply with maritime regulatory bodies. They reduce fuel consumption and harmful emissions like CO2, SOx, and NOx.

Which companies provide Rotor Sail technology?

Norsepower, Anemoi, and Hyundai are industry leaders in providing Rotor Sail technology. They’ve installed rotor sails on various types of vessels.

What materials are used to construct Rotor Sails and how are they controlled?

Rotor Sails are made from lightweight composite materials and steel. Control stations regulate the sails’ speed and direction, with some systems offering automatic monitoring for optimal operation.

- Sustainable and Luxurious: Discovering Split’s Yachting Paradise – April 26, 2024

- MarineTraffic vs VesselFinder: Which Is Better Vessel Tracking Service? – February 14, 2024

- Port Costs: A Comprehensive Guide to Port Dues and Fees for Cargo Ships – February 12, 2024

Leave a Reply