Oil rigs are an important part of the oil and gas industry. They are large structures with facilities to extract and process petroleum and natural gas from the ground, They are sometimes referred to as oil platforms or oil and/or gas production platforms. There are different types of oil rigs, each with its advantages and disadvantages.

What Do Oil Rigs Do?

Oil rigs are a type of drilling platform used to extract petroleum from under the earth. They are typically large, tower-like structures that are installed on the ocean floor. Oil rigs can be used to drill in both shallow and deep water formations.

The primary purpose of an oil rig is to extract oil and gas from the earth and to do this they are equipped with a variety of drilling equipment and machinery that is used to break through the earth’s surface and extract hydrocarbons. Once the oil and gas have been extracted, it is transported to onshore processing facilities where it is refined and sold.

Types of Oil Rigs

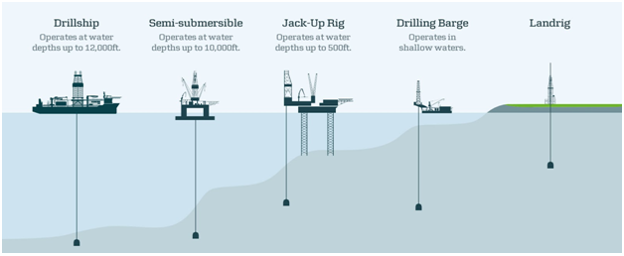

Oil rigs come in all shapes and sizes. There are three main types of oil rigs: offshore, onshore, and floating rigs. Offshore oil rigs are located in the ocean and are the most common type of rig. They can be found in a variety of water depths, but are typically situated in deep water. Offshore rigs are used to drill in both shallow and deep waters.

Onshore oil rigs are located on land. They are used to drill in areas that are close to the shore and can be found in a variety of environments, including desert, swamp, and tundra. They can also be used in shallower waters and are much less expensive to build and operate. However, they are not as mobile and can be affected by bad weather. They are generally classified by their maximum drilling depth and their mobility.

Floating oil rigs are the most mobile type of rig. They are used to drilling in offshore areas that are too deep for traditional rigs to work in.

There are two main types of floating oil rigs: drillships and semi-submersibles. Drillships are used to drill in areas that are too deep for traditional rigs to work in. They have a large drilling tower that rises above the ship. This tower allows the drillship to drill in water depths of up to 3,000 meters.

Semi-submersibles are used to drill in areas where the ocean floor is too soft for a traditional rig to stand on. These rigs have a large metal frame that sits on the ocean floor. The frame is partially submerged in the water, which allows it to stay stable even in rough seas.

Onshore rigs on the other hand are used in shallower waters and are much less expensive to build and operate. However, they are not as mobile and can be affected by bad weather. They are generally classified by their maximum drilling depth and their mobility.

Oil rig design and construction are influenced by factors such as variations in expected sea level, weather conditions, and a desire for platform mobility. This has resulted in the design of many different types of rigs. The following are the different types:

Spar Platform

Spar platforms are semi-submersible platforms that are used in the offshore oil and gas industry. It is made up of large-diameter, vertical buoyant cylinders that support a deck. The buoyant cylinder(s) are secured to the seafloor by a spread-mooring system made up of either a chain-wire-chain or a chain-polyester-chain configuration.

Spar platforms are traditionally moored to the seabed and use counterbalance for stability. They are similar to tension-leg platforms, but because of their increased stability, they can be used in more difficult waters.

The main advantage of the spar platform is that it is very stable in rough seas. This makes it an ideal platform for use in deepwater environments.

Tension-Leg Platforms

A TLP, or tension-leg platform, is a large floating structure used in the offshore oil and gas industry. It is a self-contained drilling and production platform supported by three or more ocean-floor-attached legs (pillars). The TLP was created in the early 1970s to provide a more stable alternative to the traditional jack-up rig.

The buoyant hull and the mooring system are the two main components of the TLP. The buoyant hull is made of steel or concrete and is intended to keep the ship afloat even in rough seas. The mooring system is made up of anchors and cables that secure the buoyant hull to the seafloor.

A tugboat tows the TLP to its final destination. Once in place, the tugboat releases the anchors, which pull the buoyant hull down to the seafloor. The buoyant hull is then held in place by the mooring system.

This type of drilling platform is a massive floating vessel. The platform is supported by massive columns that are attached to large pontoons. It stays in place during drilling by using dynamic positioning systems (thrusters) or anchors. The BP Deepwater Horizon was a drilling rig of this type

Semi-Submersibles

Semi-submersibles are the most stable of the floating rigs. When drilling in rough waters, oil companies will frequently use semi-submersibles due to their ability to remain stationary in less-than-ideal conditions. Modern rigs can drill to depths of less than 1,000 meters, and the most recent can reach depths of less than 3,000 meters.

Drillships

Drillships are the most in-demand drilling rigs right now. The majority of the drilling platforms currently under construction are drillships. This is because drillships are a faster alternative to semi-submersibles. While semis can take over two months to reach a new location, drillships can do so in three weeks.

Drillships have the advantage of being able to operate in remote locations with fewer supply trips. Furthermore, because of their mobility and increased depth capabilities, owners can charge more per day for use. They are, however, less stable than the average semi-submersible.

Compliant Towers

Compliant towers are slender, flexible towers with a concrete pile foundation. This structure is designed to sustain significant lateral forces, and it can operate in water up to 2,990 feet deep.

Condeep Platforms

Condeep platforms have a concrete base with one or more concrete shafts extending upward. The platform’s bulk is submerged. Due to their ability to survive harsh weather and deep water, these platforms are mostly used in the North Sea and on the Norwegian continental shelf. weather

Fixed Platforms

Fixed platforms are attached directly to the bottom and are designed for long-term use. These platforms can work in up to 1,710 feet of water.

Normally Unmanned Installations

Normally Unmanned Installations (NUIs) are platforms that operate without a crew and commonly are relatively small platforms.

Jack-Up Rigs

For shallow wells, jack-up rigs are used. The oil platform can move up and down the legs as water levels change, standing on three (often four) legs anchored to the ocean floor. This technology gets its name from the platform’s ability to “jack” up and down. Jack-up rigs provided the first stable platform for drilling oil offshore. These rigs began to sprout all over the shores of the United States.

Although the first jack-up rig was built in 1954, technological advancements continued to improve it far into the 1980s and 1990s. As of 2013, there were 540 jack-up rigs in operation around the world. Today’s “premium” jack-up rigs can drill to depths of up to 400 feet (which is now considered shallow in the industry).

How do Deep-sea oil rigs float?

Oil rigs use a variety of methods to stay afloat. Some rigs are mobile and can move from one location to another as needed. Others use large metal hulls that keep them above the water. The most common method for keeping rigs afloat is through the use of large, buoyant tanks known as “flotation cells.”

These tanks are filled with either air or gas and help to keep the rig in place. They also act as a buffer against waves and storms and help to reduce the amount of noise and vibration that is transmitted to the ocean floor.

How do oil rigs move?

Oil rigs are designed to be sturdy and mobile. They need to be able to withstand the harsh conditions of the ocean, as well as be moved from one drilling location to another.

The base of the rig is mounted on a large platform called a jack-up barge. The barge has large legs that can be lowered into the water. When the legs are in the water, they support the weight of the rig.

The rig is then towed to its new location by a large tugboat. The tugboat uses a special cable to connect to the rig. The cable is attached to a large winch on the tugboat. The winch pulls the cable tight, and the rig is moved to its new location.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025