Have you ever wondered about the materials used to construct ships or about the ship’s primary components?

A ship is constructed of steel and composite materials and is composed of both visible and unseen structural components.

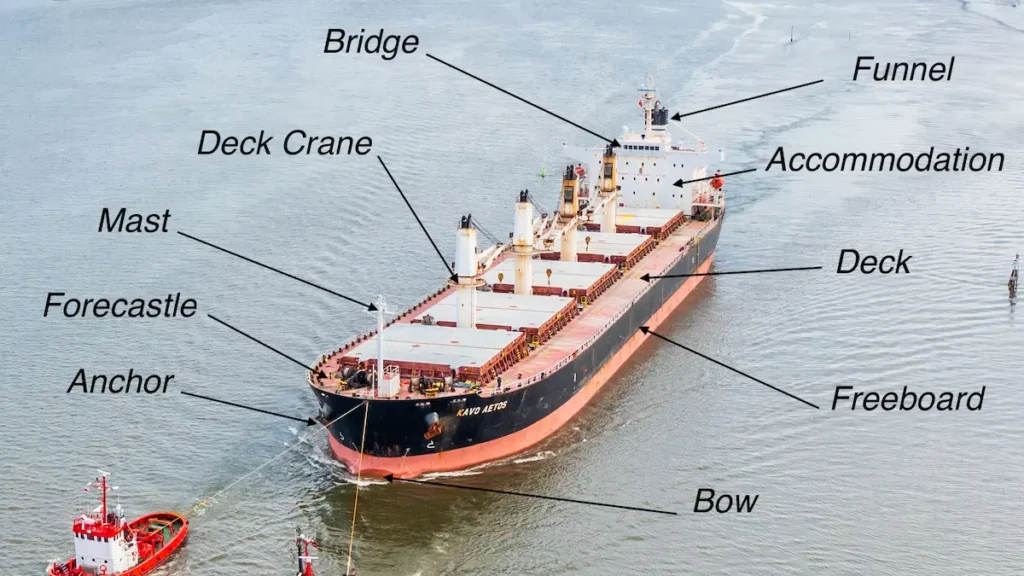

In this article, we will look at the different parts of a ship and break down their functions, including the visible components such as the rudder, anchor, accommodation, bow, deck, hatch covers, mast, deck crane, bridge, propeller, and bow thrusters, as well as the unseen structural components like bulkheads, keel, frames, cargo holds, hopper tanks, double bottoms, girders, cofferdams, and side shells.

What Are The Different Parts Of Ships?

From the visible to the unseen, ships are complex structures with numerous components crucial for their operation and safety. Let’s dive into the essentials of ship design, highlighting both the prominent and hidden parts that ensure a vessel’s integrity and functionality.

Visible parts like the rudder, anchor, accommodations, bow, hatch covers, mast, keel, bridge, propeller, and bow thrusters are familiar sights on a ship. However, the integrity of a ship relies heavily on its unseen structural components. These include bulkheads, frames, cargo holds, hopper tanks, double bottoms, girders, cofferdams, and side shells, all vital for a ship’s structural integrity and the safety of its crew and cargo.

Navigating the terminology of ship design can be challenging, with terms like port (left side when facing the bow), starboard (right side), ahead (front), and astern (rear) used to describe a ship’s orientation. Understanding these terms is key to grasping the full scope of ship components.

Anchor

An anchor is a massive piece of heavy metal that is connected to the chain cables and stored or fastened in the hosepipe during the journey/ship operation. It may be permanent or temporary, with the addition of a marine anchor category.

All ships carrying anchors are temporary since they are not permanently moored in one location and are often dropped at other locations based on the conditions. Anchor gear includes chain cables, connecting devices, a windlass, and a chain stopper.

An anchor’s five fundamental components are the shank, the crown, the stock, the flute, and the tripping ring. A shank is an integral stem that is permanently linked to the flute through the shank hole.

These linking structures, together with the stack, are referred to as anchor crowns – a crossbar that assists in twisting the anchor and helping the flute dig into the soil.

The fluke is a critical component of a ship’s anchor because it burrows deep into the soil to secure the ship.

While the majority of ships go between ports, a tiny percentage are forced to wait for berths outside. Due to rising trade and an expanding fleet of ships, it is becoming more normal to have to wait a long time for a berth.

The ship’s anchor plays a crucial role in protecting the ship from natural forces such as wind and tidal currents during this waiting period. They serve as a stabilizing hand, anchoring the ship precisely with their flutes hooked deep into the seafloor and the chain’s weight and resulting force.

Bow

A bow is the forward-most section of a ship that cuts through the water along its sides as it travels. The two primary requirements for a bow are that it must have the least drag possible, or so-called resistance, between the water and the ship’s hull, and that it must be tall enough to prevent water from splashing readily on top of it.

Only a few bow varieties have stood the test of time throughout history: the bulbous bow, the inverted bow, and the ax bow.

A bulbous bow is the kind of bow seen on the majority of ships, especially those used in commercial transportation. It is immediately identifiable by its distinctive bulging bulb-like form just below the waterline, and it has the benefit of increasing a ship’s fuel economy by 10% to 15% of total ship fuel consumption steaming, so the ship has to carry less fuel onboard.

On the other hand, a ship with an inverted bow design has the hull and bow sections reversed, similar to a submarine with an extended waterline. On the one side, this increases its water drag, while on the other, it reduces its reserve buoyancy and speed in inclement weather.

This style of bow is often seen on ships engaged in anchor handling, deep-sea pipe installation, and offshore operations.

Ax bows feature a vertical stem line hull construction, as well as a deep Axe-like structure in the ship’s front section. It is one of the ship’s components that, owing to its design capabilities, contributes to the ship’s increased speed with the same power.

Have you noticed how much more work it takes to walk through water? This is due to the drag caused by the water and its resistance to your body’s motion. Thus, to mitigate comparable negative forces acting on the ship’s body, a bow is added to aid in simple propulsion.

Bow Thrusters

Bow thrusters are propeller-like devices mounted on both sides of the ship’s bow. It is used to improve a ship’s maneuverability in crowded waterways, such as canals or areas next to ports.

Most designs include an impeller in a tunnel that runs through the bow of the ship. Bow thrusters are sometimes referred to as tunnel thrusters because of their odd appearance. The impeller may be rotated clockwise or counterclockwise, providing bidirectional propulsion capability.

Bow thrusters significantly reduce a ship’s total operating costs by compensating for part of the tug assistance charges levied by the port. Proper bow thruster marks above the waterline on both sides are crucial.

Electrical power is used to power these thrusters, with the prime mover coupled to the impeller shaft through a bevel gear arrangement. On some ships, hydraulic propulsion is also used when an electrical propulsion system is neither feasible nor accessible.

Propulsion and rudder angle changes are used to operate a ship. A rudder is a horizontally oriented blade-like device located behind the propeller that is used to direct the ship. The angle of the rudder is adjusted to achieve the desired direction change.

However, what if the ship’s speed is too sluggish for the rudder angle to manage effectively? This happens when the skipper uses bow thrusters to help him control the ship at extremely low speeds.

Accommodation

It is a section of a ship where the crew lives or dwells. It houses the ship’s offices, crew quarters, gym, prayer room, salon, recreation area, laundry, hospital, and galley, in addition to the engine room and navigational bridge on the ship.

A salon is a common room or living space onboard that is used by the crew, passengers, and any visiting authorities; it often includes a shared lounge and dining area. On the other hand, the galley is a nautical phrase for the kitchen; it refers to the location of food preparation.

As a significant component of the ship, accommodation is responsible for a variety of systems, including freshwater, domestic refrigeration, waste disposal, the sewage treatment plant, and the air conditioning in the accommodation block.

International and national maritime regulations require all vessels, including passenger ships, cargo ships, salvage ships, tugs, and dredgers, to offer accommodation above the summer load line aft or amidships of the ship structure.

The term “accommodation” refers to the ship’s living quarters. The Marine Labor Convention (MLC 2006-2007) stipulates that suitable housing and recreational facilities must be provided for ship personnel and commanders.

This involves adequate provisions for the crew’s safety, housing, and health and for on-board events. Hospital facilities, enough ventilation, lighting, headroom, and heating, as well as crew rooms of a respectable size, are now necessary.

Deck

A deck is a structural feature that acts as the floor or covering for the hull structure of a ship. A ship may have many decks, each of which is positioned in a distinct portion or segment of the ship; for instance, an upper and lower deck, or decks 1, 2, and 3 in increasing order. This means that the main deck or weather deck is the highest deck exposed to the elements.

Deck 1 and Deck 2 refer to the levels and floors under the weather deck. Level decks or floors, on the other hand, do not extend from aft to front.

A ship’s six separate decks are the main deck, upper deck, poop deck, weather deck, lower deck, and foredeck. The term “main deck” refers to a ship’s main deck, which runs the length of the vessel.

It is also the highest deck on the majority of ships, which is why it is referred to as the upper deck; but, on warships, it is a separate deck under the top deck. The phrase “lower deck” refers to the deck underneath the upper deck, while “weather deck” refers to any part of the ship exposed to the elements.

The poop deck is the area of the deck on the ship’s rear side, while the foredeck is the area of the deck between the cabin and forecastle.

A deck is one of the ship’s many components; it is the plane that supports the hull construction and serves as the ship’s distinct selling floor. Additionally, it offers room and a floor for equipment and personnel to stand and work in a climate-controlled atmosphere.

The Hull

A hull is the portion of a ship that extends below the waterline to contain and prevent water entrance. Consider it to be the protective shell that protects the inside gems from the elements.

The ship’s hull encloses and protects everything stored and situated inside the ship’s primary structure. It includes all key components of the ship, including the bow, deck, bottom keel, and both sides.

They are made up of a series of plates joined by stakes, as well as structural parts such as plating and stiffeners.

Stiffeners are constructed using structural components such as transverse and longitudinal frames, girders, bulkhead stiffness, and beams. While ship plating is most often associated with the deck, it also encompasses the bottom, bulkhead, and side plating.

A ship’s hull is designed in such a manner that it provides the least resistance to water, is feasible and economical to make, and does not lose critical cargo capacity.

By measuring and minimizing the resistance to motion of the ship’s hull, one may easily evaluate and improve the ship’s overall efficiency.

The principal purpose of a ship’s steel hull is to maintain its watertight integrity and reduce drag. Thus, the hull is crucial in determining the overall efficiency of a ship.

Thus, ships’ hulls are coated with specialized paints that reduce frictional drag while simultaneously inhibiting marine growth, which increases the resistance to ship motion. Thus, the ship’s hull is cleaned and repainted with a special coating during dry dock operations.

Keel

A keel is a structural component of a ship’s hull that adds to the structure’s strength by evenly distributing stress and strain longitudinally.

Due to its ability to maintain and sustain the ship’s structure, it is sometimes referred to as the ship’s backbone. In basic terms, it gives the ship stability and increases its effective speed.

In shipping, introducing keels alleviated a significant amount of labor associated with ship structural stabilization.

It was initially utilized by Vikings to minimize their ships’ lateral movement during that period. A keel is just a thick plate running longitudinally across the ship from the bow to the stern, passing through the ship’s bottom construction centerline.

In the maritime sector, three fundamental kinds of keels are used: flat keel, duct keel, and bar keel. All big ships in operation have flat keels; bar keels are employed when the ship must operate in shallow water, and duct keels are used on offshore vessels and double-hulled tankers.

It is a critical component of the ship, contributing to the structural stability and support of the vessel. Additionally, it contributes significantly to a ship’s effective speed.

With a ship’s displacement determined by the distance between the keel and the waterline, knowing the ship’s draught and reserve buoyancy is advantageous. If you go much deeper into this topic, then this article about ship keels is for you, but we move on.

Freeboard

The term “freeboard” refers to the portion of a ship’s hull visible above the waterline. It is the distance between the ship’s top deck and the waterline. A ship’s freeboard is not set but varies according to the quantity of cargo carried.

At all times, a minimum freeboard is essential to prevent the ship from sinking. Thus, to maintain the safety of ships at sea, load line marking is employed to ensure that the ship’s draught is as large as feasible while still completing the journey safely.

A ship’s minimum freeboard is defined by the distance between the upper deck and the load line. The international agreement on load lines requires that a minimum freeboard be maintained at all times (ICLL 1966).

This limits the number of goods that can be loaded onto a ship. By regulation, ships must load only up to the load line marker for the appropriate water type. As a consequence, ships’ hulls must have precise load line markings on both sides.

The purpose of freeboard between various sections of a ship is to keep it stable and prevent it from sinking. Tropical Freshwater, Tropical Freshwater, Summer, Winter, and Winter North Atlantic load line markings on ship hulls are required by ICLL 1996 on ship hulls. These load lines help ensure the ship has enough freeboard for a safe trip.

Engine Room

The engine room is functionally the heart of any vessel, this part of the ship is positioned on the lowest deck aft. It is used to store mission-critical equipment such as the main engine, boiler, fresh water generator, alternator, shafting, air compressor, pumps, purifier, heat exchangers, incinerator, and repair types of machinery.

When asked about the engine room, a mariner’s immediate response is that it is hot, loud, and vibrating. The engine room’s average temperature is always more than 45 degrees centigrade.

The engine room’s equipment is properly classified into three distinct decks: utility deck, weather deck, and mechanical deck. It is frequently referred to as the ship’s heart when equipped with all propulsion and auxiliary systems.

Remote management of the engine’s whole transmission is possible through a control room dubbed the Engine Control Room, or ECR for short. It is the engine room’s lone location that gives relief from the heat and noise.

The engine room’s primary responsibility is to house the ship’s critical equipment and auxiliary systems.

On deck one, control panels for diesel generators and pumps are often located, along with a workshop, a storeroom, settling tanks, service tanks, freshwater expansion tanks, an inert gas platform, a deck air compressor, and air bottles.

On deck two, you’ll find fuel oil heaters, purifiers, boilers, the ship’s primary air compressor, diesel generators, and a freshwater generator, among other things.

Deck three is mostly used to house the primary engine, several supporting coolers, and oily water separators.

Funnel

The exhaust gasses are discharged into the atmosphere through a funnel. Consider it the ship’s chimney. It has been a vital feature of the ship’s construction since the advent of mechanical ships.

The cross-section or breadth of these funnels is mostly determined by the quantity of exhaust produced by the engine room.

It was originally used to discharge everything emitted by the ship; however, it is now employed within the confines of regulated emission with shot collection in place to prevent pollution.

After collecting all of the shots in the shoot collection tank, it is subsequently discharged to the port authority. If this is not practicable, they are released overboard through an eductor, the time and quantity of which are recorded in a rubbish log book.

If you look closely, you will see that these funnels are not quite straight but rather angled. This is done purposefully to aid in the movement of flue gas away from the navigation bridge and the ship’s deck.

A funnel, as one of the ship’s components, is responsible for securely venting exhaust gas generated in the engine room to the outside environment.

In conjunction with the ship’s forward speed and the funnel’s tilt toward the aft, exhaust gas is readily pushed away from the ship, eliminating potential obstructions to ship navigation.

If the engine room is the ship’s heart, the navigation bridge is its brain. It is a large platform connected to the top of the cabin that serves as a navigational aid.

They are often assisted by an extra short passage known as a bridge wing; this allows a larger and clearer view of the outside, facilitating safe ship maneuvering.

The pilothouse is the bridge’s most critical component since it is where the ship is commanded and directed. It should be constructed in line with maritime norms and rules to provide a clear vision from the conning position to 1200 port to 1200 starboard.

From his or her vantage point on the navigation bridge, the duty officer commands, supervises, and maneuvers the ship. Normally, on the navigation bridge, a skilled sailor sits beside the duty officer.

When performing hazardous maneuvers or approaching port, the captain must be present in the navigation room with an assisting duty officer, an experienced sailor, and a pilot.

The bridge of a ship is equipped with a gyroscope, radar, magnetic compass, autopilot, echo sounder, rudder angle indicator, global positioning system, AIS, ship’s horn, navigation lights, and signaling flags, among other things.

The navigation bridge’s purpose is to give officers enough room to see and maneuver securely. Additionally, it has the technology and controls required to alter the ship’s speed and direction, as well as monitor and generate appropriate communication channels.

Deck Crane

While not all ships carry them, the majority do to aid with cargo operations and, if required, cargo adjustments throughout the journey. Apart from that, they are utilized to load and unload the ship’s hose, tools, and equipment.

They are deck-mounted and powered by an electric motor (or, in certain cases, hydraulics), with a lifting capacity of up to 50 tonnes. These cranes are seen as a vital component of typical cargo ships.

Forecastle

The forecastle is the ship’s most forward section. It is the front section of the ship’s upper deck and does not exceed 7% of the deck’s overall length. On a ship’s construction, it is immediately identifiable by a sharp rise in the foredeck toward the ship’s bow.

Historically, a ship’s forecastle was used only to establish defensive positions for a soldier aboard a military vessel. It is now mostly used to store and preserve critical ship components.

It is an anchoring tool and ground tackle hose that includes, but is not limited to, the following components: haws pipe, windlass, open rail, anchor chain, hydraulic motor, chain block, deck flange, bollard, gearbox, anchor, and foremast.

It is often used for anchoring and inspecting or maintaining the foremast navigation lights.

The forecastle, or beginning part of the foredeck, is a critical structural component of the ship since it houses the anchoring equipment. Apart from providing tools and equipment for anchoring, the forecastle aboard naval ships serves as a storage location for key defense cannons.

Propeller

It is a mechanical device, similar to a fan, that has blades that are attached. For a ship to go forward, it must spin in tandem with the shaft to provide the required push.

It is the propeller of a ship that generates propulsion by transforming the rotational energy produced by its blades into pressure energy.

This is accomplished by forcing the water away from the blade’s near and far sides, exploiting the pressure differential between the two sides.

It does this by using Newton’s third law of motion in conjunction with its components, which include the hub, blades, and faces, to provide the push necessary for propulsion.

By Newton’s third law of motion, every action results in an equal and opposite response. Using its propeller, the ship drives itself ahead by pushing the water backward, providing a net resultant force of equivalent magnitude that propels the ship forward.

As part of a ship’s propulsion system, which also comprises the engine and the engine’s shafts (including intermediate and propeller shafts), as well as the propeller itself, a propeller is referred to as a propeller. The propeller, which is one of the most important parts of a ship, is made up of non-corrosive alloys like manganese bronze and aluminum to ensure long service life.

A ship is rendered ineffective if it is not moving; as a result, ships are fitted with propellers to produce forward movement. For this reason, the propeller’s role in a ship is to give the vessel much-needed propulsion.

Propellers are divided into four primary varieties based on the number of blades they have and two broad groups based on their pitch.

Depending on the pitch of a propeller, it may be classified as either a fixed pitch or a variable pitch propeller.

Similarly, the number of blades can be three, four, five, or six, depending on the number of blades present.

Rudder

A ship’s rudder, in contrast to its propeller, is a component that steers it as it travels forward. It is a flat hollow device situated aft of the propeller that rotates on its axis from port to starboard to assist the captain in guiding the ship in the right direction.

To function properly, a rudder must have various components, including a trunk, primary rudder blade (with movable flap), links, hinge system, and a rudder carrier bearing. The rudder, like the propeller, works in conjunction with Newton’s third law of motion to steer the ship in the desired direction.

In the process of flowing, it creates resistance to water flow, forcing it to move in the opposite direction of its original flow. Using a similar mechanism, the ship may generate the force necessary to steer away from the changing water flow.

The way a rudder is built impacts whether it is balanced, semi-balanced, or unbalanced in operation. A balanced rudder has at least 20 percent of its componentry located in front of the turning axis of the boat’s sail.

An unbalanced rudder, on the other hand, has no component outside or ahead of its turning axis, while the component of a balanced rudder is less than 20% of its total component.

The rudder of a ship is the component that allows it to navigate through the water. Following Newton’s third law of motion, it creates a sufficient resultant force to steer a ship in the desired direction. The steering gear system is responsible for controlling the movement of the rudder.

When going from 35 degrees port to 35 degrees starboard, the rudder must be capable of doing so in fewer than 28 seconds, and the steering gear must be capable of changing from 35 degrees in one direction to 30 degrees in the other.

Mast

In a ship, a mast is a vertical structure that extends forward of the forecastle and toward the bow of the vessel. It has a connection to the peak of the bridge.

It serves to support the ship’s derrick and to house important equipment such as radars, navigation lights, and, in the case of a foremast failure, the ship’s horn, among other things.

They are made of high-tensile steel with greater rigidity to withstand the weight of the derricks on top of them. Furthermore, the main mast of a ship is used to hoist the ship’s flag, which is another important function.

In addition to its other functions, the mast’s principal duty is to hold necessary equipment such as a radar receiver, navigation lights (including the ship’s horn), flags (including the ship’s ensign), and, in certain situations, derricks.

Final Thoughts

Ships, a vital means of seaborne transportation, come in a range of shapes and sizes. Certain components are classified as required since they are present on all ships, while others are classified as accessories because they contribute to the luxury or better shipping experience.

Each component of the ship should be examined for proper functioning, and protections should be put in place for harmful equipment.

Three key components of a ship are the hull, navigation bridge, and engine room. Contemporary ships, on the other hand, are equipped with the most current techniques and technologies across their many components to facilitate sea navigation.

- Types of Gas Carriers as per IGC Code – April 22, 2025

- Wind-Assisted Propulsion Systems (WAPS): A Game Changer for Maritime Decarbonization – February 6, 2025

- 10 Boat Salvage Yards in California – January 25, 2025